Why Soft Pour Play Surfaces Are Revolutionizing Playground Safety

Soft pour play surfaces are seamless, poured-in-place rubber surfacing systems that provide superior safety, accessibility, and durability for playgrounds and recreational areas. These surfaces consist of two layers: a shock-absorbing base made from recycled tire rubber and a colorful, weather-resistant top layer that can be customized with designs, logos, and multiple colors.

Key Benefits of Soft Pour Play Surfaces:

- Safety: Meets critical fall heights up to 13 feet per ASTM F-1292 standards

- Accessibility: ADA-compliant seamless surface for wheelchairs and mobility devices

- Durability: 12-15 year lifespan with minimal maintenance

- Customization: Available in 24+ colors with design flexibility

- Sustainability: Made from recycled tire rubber, diverting waste from landfills

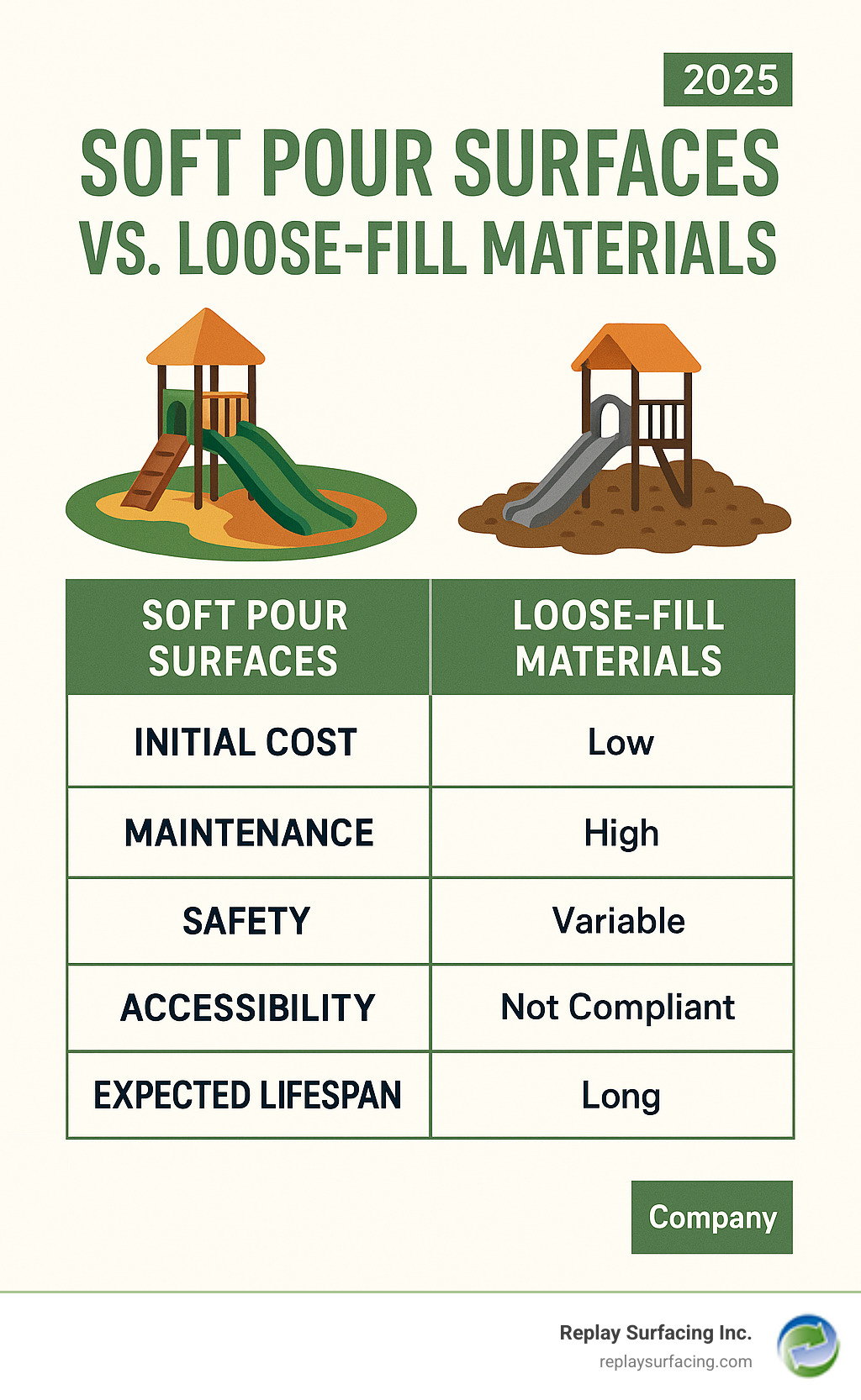

With falls accounting for nearly 70% of all playground injuries, choosing the right surface material has never been more critical. Traditional loose-fill materials like wood chips and sand compress over time, lose their protective qualities, and create accessibility barriers. Soft pour surfaces solve these problems by creating a permanent, level playing field that protects children while accommodating users of all abilities.

The maintenance benefits are equally compelling – while loose-fill materials require constant replenishment and raking, soft pour surfaces need only routine cleaning and occasional resealing every 18-24 months to maintain their protective properties and vibrant appearance.

I’m Landon Olson, a mechanical engineer and MBA who has dedicated my career to changing scrap tires into innovative soft pour play surfaces through my company, Replay Surfacing. With experience spanning manufacturing, sustainability, and safety surfacing, I’ve seen how these surfaces create safer, more inclusive play environments while supporting environmental goals.

Essential soft pour play surfaces terms:

What Are Soft Pour Play Surfaces?

Imagine stepping onto a playground where the ground feels like one giant, colorful cushion. That is exactly what soft pour play surfaces – also called poured-in-place rubber or wet pour rubber – deliver.

Instead of installing pre-made mats or tiles, we blend rubber granules with a polyurethane binder right on site. The result is a single, seamless surface that follows every curve of your playground, leaving no gaps, joints, or trip hazards.

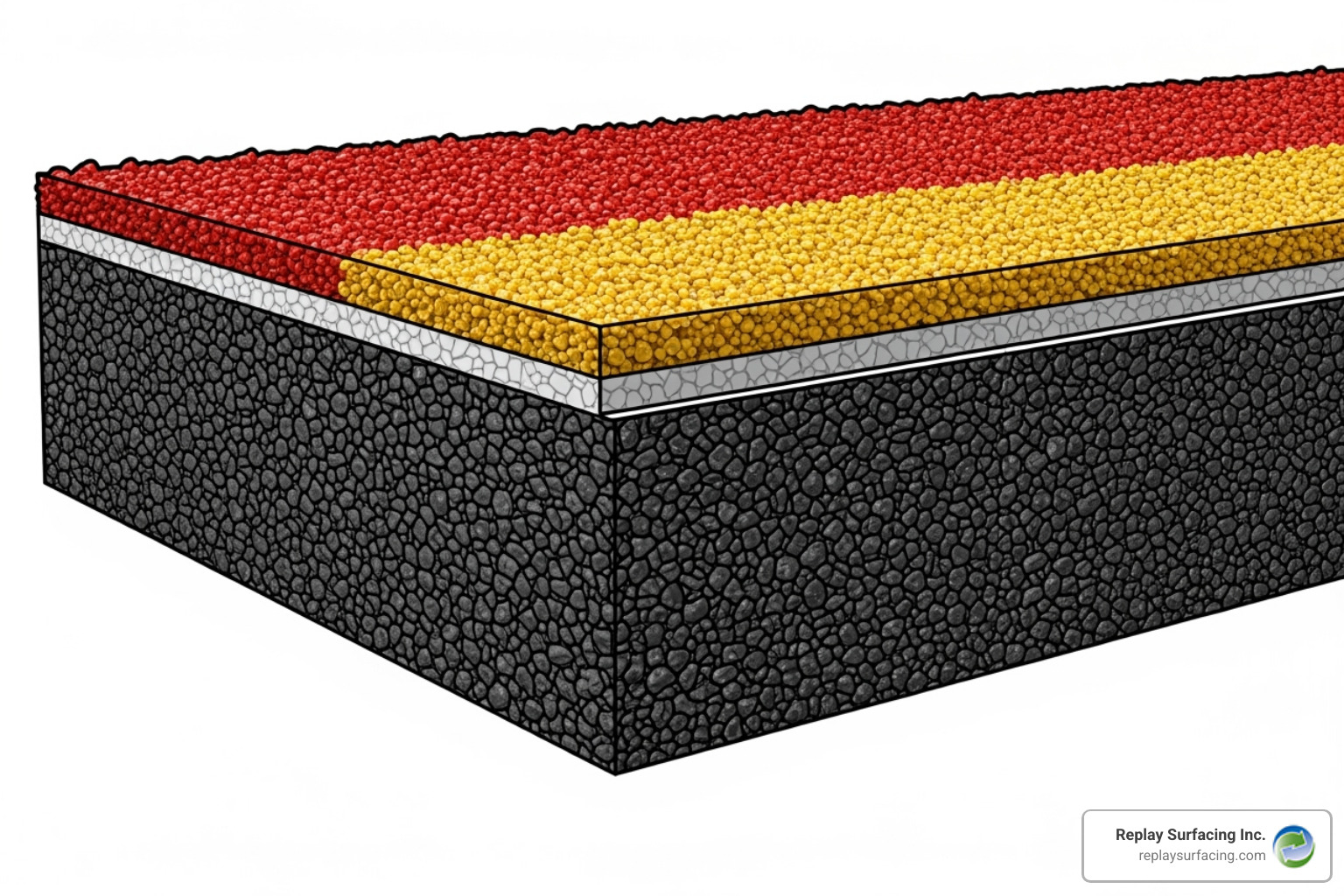

The system has two jobs – and two layers:

- Cushion layer (bottom) – Recycled SBR tire granules mixed with binder create a thick, shock-absorbing pad that meets fall-height requirements.

- Wear layer (top) – Colorful EPDM granules form a tough, UV-stable shell that resists weather, fading, and daily traffic while showing off school colors, games, or logos.

On-site installation lets us vary thickness (extra under swings, less under benches), integrate wheelchair-friendly ramps, and even hand-trowel hopscotch, foursquare, or mascot art right into the surface. Because nothing is loose, you never have to rake, refill, or chase scattered pieces.

For communities that want a long-lasting, low-maintenance answer to playground safety, poured in place rubber the ultimate playground safety surface remains the clear choice.

The Anatomy of a Soft Pour Surface: Materials and Composition

Think of a soft pour surface like a performance shoe sole: cushioning underneath, durability on top.

The Cushioning Base Layer

- Material: SBR (Styrene-Butadiene Rubber) from recycled tires. A 1,000 ft² playground redirects roughly 500-600 tires from landfills.

- Purpose: Absorbs impact. Thickness is custom: 2-3 inches for 6-ft falls; 4-5 inches for 10-12-ft falls.

- Binder: Polyurethane keeps the layer porous so rain drains through while the surface stays soft.

The Durable Wear Layer

- Material: Virgin EPDM granules (1-4 mm) for consistent color and long-term UV resistance.

- Thickness: About ½ inch, creating a comfortable, slip-resistant finish.

- Customization: Over 24 stock colors (plus custom blends) allow school logos, games, or shaded walkways. Modern EPDM keeps those colors vibrant for years – no patchwork fading.

The Binding Agent

Polyurethane binders lock every granule in place:

- Aromatic binders – Most economical; slight yellowing fades with use.

- Aliphatic binders – Crystal clear, superior UV stability; ideal for bright blues, teals, and light shades.

Both options are UV-stable, antimicrobial, and flexible enough for splash pads, pool decks, and extreme weather.

Safety and Accessibility

Playground falls cause nearly 70 percent of injuries. The surface beneath equipment is the single biggest factor in how serious those injuries become.

Critical Fall Height and Impact Attenuation

ASTM F-1292 testing sets two key numbers:

- HIC (Head Injury Criterion) – must be below 1,000; our surfaces routinely test below 500.

- G-MAX (peak deceleration) – must be under 200; we average under 100.

Loose-fill materials compact, scatter, and quickly lose up to 25 percent of their shock absorption. Poured-in-place rubber maintains its protection for 12-15 years.

Ensuring Accessibility for All

A perfectly smooth, seamless finish meets ADA and ASTM F-1951 standards. Wheelchairs, walkers, and strollers roll effortlessly, and caregivers with limited mobility don’t struggle over shifting mulch. Hand-troweled ramps can be blended right into the surface – no separate parts, no new trip points.

Key Industry Certifications

Third-party IPEMA certification confirms every mix we install meets or exceeds safety and accessibility benchmarks. It’s extra paperwork for us, iron-clad peace of mind for you.

The Step-by-Step Installation Process for Soft Pour Play Surfaces

Installing a soft pour surface isn’t DIY weekend work – it’s a four-stage craft.

1. Site Preparation

Stable sub-base is everything. We clean, repair, and, if needed, compact Type 2 stone to 95 percent density or inspect concrete/asphalt for cracks and drainage.

2. Mixing the Materials

Special mixers blend rubber and binder on-site. Ratios change with granule size, temperature, and humidity, so crews adjust in real time and log every batch for quality assurance.

3. Pouring and Troweling

Base layer first, then wear layer. Hand-troweling guarantees uniform thickness and lets us embed hopscotch courts, logos, or color blends that wetpour soft surfaces are famous for.

4. Curing and Finishing

Binder needs 24-48 hours (50-85 °F, dry weather) to cross-link into a resilient sheet. After a final inspection for thickness, texture, and appearance, the play area opens – usually the very next day.

Design, Durability, and Dollars: What to Expect

Endless Customization and Applications

More than 24 stock colors – and limitless blends – mean you can match school branding, add maps, or embed games. Thickness varies by fall height, saving money where heavy cushioning isn’t required. Beyond playgrounds, our playground surfaces excel on splash pads, sport courts, and walking paths.

Lifespan and Maintenance

Expect 12-15 years of service. Routine care is simple: blow or hose off debris, then roll-coat a thin sealant every 18-24 months to refresh UV protection. No raking, no top-offs, no bare spots under swings.

Understanding the Cost Factors

For projects over 1,000 ft², budgets usually fall between $9-18 per ft² installed.

Key variables:

- Size (bigger projects lower cost per ft²)

- Required thickness (based on equipment height)

- Color complexity (standard vs. custom blends)

- Substrate condition and local labor rates

Our guide on understanding rubber playground surfacing costs dives into each factor.

Frequently Asked Questions about Soft Pour Play Surfaces

How long does a poured rubber surface last?

With basic cleaning and a roll coat every couple of years, expect 12-15 years or more of dependable protection.

Is poured-in-place rubber slippery when wet?

No. The surface is porous and textured, so water drains through instead of pooling, providing grip even after rain – perfect for splash pads and pool decks.

What is a soft pour play surface made of?

Soft pour surfaces are made from recycled rubber with a durable EPDM top layer and a shock-absorbing base.

How thick should a soft pour playground surface be?

Thickness depends on equipment height. Most playgrounds need 2–5 inches to meet fall-height safety standards.

Can you install a soft pour surface over an existing surface?

Often yes. If the concrete or asphalt is sound, properly graded, and free of oil or loose material, overlaying saves demolition costs. A professional inspection will confirm suitability.

Conclusion

Soft pour play surfaces represent more than just playground flooring – they’re a revolution in how we think about child safety, community inclusion, and environmental responsibility. Through our work at Replay Surfacing, I’ve witnessed countless moments where these surfaces have transformed not just play areas, but entire communities.

Soft pour play surfaces offer a reliable way to improve playground safety, accessibility, and long-term value. They reduce fall injuries, eliminate loose-fill maintenance, and support inclusive play for all abilities. At Replay Surfacing, we help schools and communities install soft pour systems that meet safety standards and perform for over a decade.

The numbers tell an important story: with falls causing nearly 70% of playground injuries, having a surface that protects children from falls up to 13 feet while maintaining that protection for 12-15 years isn’t just a nice feature – it’s a necessity. But beyond the statistics, these surfaces create something even more valuable: spaces where every child can play together safely.

The seamless, ADA-compliant nature of soft pour play surfaces means that children using wheelchairs, walkers, or other mobility devices can access the same play experiences as their peers. We’ve seen the joy on parents’ faces when their child can finally reach playground equipment that was previously inaccessible due to loose-fill surfaces or uneven terrain.

From our locations spanning Charlotte NC, Columbia SC, Raleigh NC, Sanford NC, Tucson AZ, Connecticut, Indiana, Nashville TN, Beaverton OR, and Lake Charles Louisiana, we’ve helped transform hundreds of communities by changing what would otherwise be environmental hazards into life-protecting surfaces. Each installation represents thousands of recycled tires diverted from landfills and given new purpose as playground protection.

The financial benefits extend far beyond the initial investment. Reduced injury liability, eliminated ongoing maintenance costs of loose-fill materials, and the durability to serve communities for over a decade make these surfaces a wise long-term investment. But the real value lies in creating spaces where parents feel confident letting their children play and where communities can come together.

When you choose soft pour play surfaces, you’re making a statement about your priorities: safety first, accessibility for all, and environmental responsibility. You’re investing in surfaces that will protect children, welcome everyone, and serve your community faithfully for years to come.

Ready to create a safer, more inclusive play area? Explore our playground surfacing solutions today! Let’s work together to transform your vision into a reality that brings joy, safety, and sustainability to your community.