Why Rubber Surfacing for Pool Decks Is a Smarter, Safer, and Greener Choice

Rubber surfacing for pool decks is an innovative, sustainable way to resurface pool areas with a soft, slip-resistant, and durable layer—often made from recycled tires.

Here’s a quick summary for anyone exploring options:

| Feature | Rubber Surfacing for Pool Decks |

|---|---|

| Slip-Resistant When Wet | Yes – even better grip when wet |

| Cool & Comfortable | Stays cooler than concrete in sunlight |

| Installs Over Cracks | Can cover old, cracked surfaces without tear-out |

| Easy Maintenance | Hose off or soap and water; minimal upkeep |

| Customizable Design | Wide range of colors, patterns, and logos |

| Fast Installation | Ready to use in 24–48 hours |

| Eco-Friendly | Made with recycled rubber, reduces landfill waste |

| Long Lifespan | Lasts 12–15 years with proper care |

| Cost Range | ~$16 per sq ft poured-in-place (varies by project) |

“Rubberized pool decks are great. They are cooler than concrete.”

– Industry testimonial

Rubber surfacing is especially popular for pool decks because it combines safety (slip-resistance, shock absorption) with sustainability and visual appeal—making it ideal for both residential and commercial properties.

As Landon Olson, operator of Replay Surfacing Inc., I have spent years recycling millions of scrap tires into high-quality rubber surfacing for pool decks and other eco-friendly solutions. My mechanical engineering and sustainability background ensure you get the facts on safety, durability, and green benefits.

Quick look at rubber surfacing for pool decks:

1. What Is Rubber Surfacing for Pool Decks?

Think of rubber surfacing for pool decks as giving your old concrete a complete makeover—but with superpowers. It’s a system that combines tiny EPDM rubber granules with a special polyurethane binder to create a seamless, flexible surface that’s actually safer when it gets wet.

Here’s how it works: we take those small rubber pieces (many recycled from old tires) and mix them on-site with high-tech polymer resins. Then we hand-trowel this mixture directly over whatever you’ve got—cracked concrete, old tile, wood decking, brick, even metal surfaces.

The result looks great and feels amazing underfoot. The porous texture gives you serious grip, especially when water’s involved. It’s like your pool deck suddenly got really good rain tires.

But here’s the real genius: crack-bridging flexibility. While concrete throws a tantrum every time the temperature changes (hello, ugly cracks!), rubber surfacing just rolls with it. It can stretch and move with your deck, expanding up to 1/4 inch over bumps and irregularities without breaking a sweat.

This seamless overlay approach means we don’t have to rip out your existing surface. We’re basically giving it a brand-new life instead of sending it to the landfill.

More info about rubber pool deck surfacing

Core features of rubber surfacing for pool decks

When we install rubber surfacing for pool decks, we apply it at a 1/4 to 3/8-inch thickness. That might seem thin, but it’s the sweet spot—thick enough to cushion falls and absorb impact, but not so thick that you’re wasting money or creating trip hazards.

The 24-48 hour cure time is honestly one of my favorite features. Imagine changing your entire pool area over a weekend. Friday afternoon we start, Sunday evening you’re back to cannonballs and poolside barbecues. No weeks of construction chaos or missed swim time.

Whether you’re dealing with an indoor pool facility or your backyard paradise, this stuff adapts beautifully to both environments. The UV-stable formula won’t fade under blazing summer sun, and it laughs off chlorine splashes that would eat other materials alive.

2. Top Benefits Every Pool Owner Should Know

Picture this: your kids are running around the pool, laughing and having a blast, and you’re not constantly yelling “walk, don’t run!” That’s the peace of mind rubber surfacing for pool decks brings to families every day.

The slip resistance is honestly mind-blowing. While most surfaces become slippery death traps when wet, rubber actually gets more grippy. The porous texture channels water away while the rubber granules provide traction that works better when soaked.

Here’s something that’ll make your summer days so much better: cooler surface temperatures. We’ve all done that painful hot-foot dance across scorching concrete. Rubber surfacing stays comfortable to walk on even after hours in the Arizona sun. The porous structure lets air flow through and moisture evaporate, naturally cooling the surface.

The shock absorption is a game-changer for families with kids. When someone inevitably slips or trips, they’re landing on a surface that cushions the impact instead of concrete that hits back. It’s not a trampoline, but it’s dramatically safer than hard surfaces.

UV and chlorine stability means your investment actually lasts. While other surfaces fade, crack, or need constant resealing, quality rubber surfacing maintains its color and performance for 12-15 years. Pool chemicals that eat away at concrete and painted surfaces? Rubber just shrugs them off.

The low maintenance is almost too good to be true. A quick hose-off handles most cleaning. No scrubbing grout lines, no resealing every year, no replacing cracked tiles. Just rinse and enjoy.

According to the Consumer Product Safety Commission, slip-and-fall accidents are among the leading causes of pool-related injuries. Here are the key health and safety benefits that make the biggest difference:

- Reduces slip-and-fall accidents by creating better traction when wet

- Cushions impact from accidental falls, especially important for kids and seniors

- Eliminates hot spots that burn bare feet on summer days

- Prevents water pooling where bacteria love to grow

- Provides ADA-compliant accessible surfaces for commercial properties

- Resists mold and mildew that thrive in wet environments

Rubber surfacing for pool decks and accident prevention

Rubber surfacing for pool decks tackles the biggest safety concern around any pool: slip-and-fall accidents. The textured surface provides incredible traction that actually improves when water, soap, or pool chemicals are present.

The cushioning effect can’t prevent every accident, but it dramatically reduces injury severity when falls happen. Instead of hitting unforgiving concrete, people land on a surface that absorbs impact energy. For families with young kids or elderly relatives, this peace of mind is priceless.

ADA compliance is built right in. The slip-resistant, stable surface meets accessibility requirements while providing the comfort and safety that makes pool areas truly usable for everyone, regardless of mobility challenges.

3. Rubber vs. Concrete, Pavers & Tile: Which Wins?

When pool owners ask me which material is best, I always start with the “barefoot test.” Picture yourself stepping out of the pool on a scorching summer afternoon. With concrete or tile, you’ll be dancing from foot to foot trying not to burn your soles. With rubber surfacing for pool decks, you can walk comfortably even when it’s 95°F outside.

The heat retention difference is dramatic. Traditional concrete can reach surface temperatures over 140°F—hot enough to cause actual burns. Meanwhile, rubber surfacing typically stays 20-30 degrees cooler thanks to its porous structure that allows air circulation and heat dissipation.

Freeze-thaw cycles tell another compelling story, especially for our northern customers. I’ve seen beautiful tile installations completely destroyed after just one harsh winter. Water gets into the joints, freezes, expands, and literally rips the tiles right off the deck.

Rubber surfacing for pool decks actually gets stronger through freeze-thaw cycles. The flexible material moves with temperature changes instead of fighting them. After 15 years in this business, I’ve never had to repair freeze damage on a properly installed rubber surface.

Here’s where things get interesting from a cost perspective. Yes, rubber surfacing costs more upfront—around $16 per square foot compared to $8-12 for basic concrete. But when you factor in the 12-15 year lifespan with virtually no maintenance, it often costs less than materials that need constant sealing, crack repair, and eventual replacement.

| Material | Initial Cost | Heat Retention | Slip Resistance | Maintenance | Lifespan |

|---|---|---|---|---|---|

| Rubber Surfacing | $16/sq ft | Low (stays cool) | Excellent when wet | Minimal | 12-15 years |

| Concrete | $8-12/sq ft | High (burns feet) | Poor when wet | High | 5-10 years |

| Pavers | $12-18/sq ft | High | Moderate | Moderate | 10-15 years |

| Tile | $15-25/sq ft | High | Poor when wet | High | 8-12 years |

The expansion joint issue drives me crazy with traditional materials. Those ugly saw cuts and caulk lines collect dirt, algae, and debris. They always fail eventually, creating trip hazards and maintenance headaches. Rubber surfacing eliminates expansion joints entirely because the whole surface moves as one flexible unit.

More info about non slip pool deck surfaces

Choosing the right deck material for your climate

Climate makes a huge difference in material performance. In our sunbelt markets like Tucson and Charlotte, surface temperature is everything. I’ve measured concrete pool decks at 150°F on summer afternoons—that’s literally hot enough to cook an egg. Rubber surfacing for pool decks stays comfortable enough for bare feet even in extreme heat.

Coastal areas bring their own challenges with salt air and constant humidity. Salt is incredibly corrosive and finds its way into every crack and joint in traditional materials. The porous nature of rubber surfacing actually helps here—water and salt can drain through instead of sitting on the surface causing damage.

Northern climates are where rubber surfacing really proves its worth. Those brutal freeze-thaw cycles that happen 50-100 times per winter destroy rigid materials. The flexibility of rubber surfacing means it actually benefits from these temperature swings, becoming more integrated and durable over time.

4. Installation Options: DIY Kits vs. Professional Poured-in-Place

Choosing how to install rubber surfacing for pool decks depends on your skills, budget, and tolerance for risk. After seeing both approaches play out hundreds of times, I can tell you the choice matters more than most people realize.

DIY kits work best for smaller areas—think 200 square feet or less. Beyond that, you’re looking at multiple days of intensive physical labor. You’ll need a wheelbarrow, mixing paddle, trowels, and perfect weather conditions. One thunderstorm can ruin hours of work.

Professional installation transforms the experience completely. We handle all the site preparation—cleaning, crack repair, and surface evaluation. This prep work matters more than most people realize. Skip it, and you’ll see telegraphing cracks and adhesion failures within a year.

The mixing process is where experience really shows. EPDM granules and polyurethane binders must be combined in precise ratios. Too much binder creates a slippery surface that defeats the whole purpose. Too little, and granules start coming loose after a few months. We mix small batches continuously to maintain consistency across the entire deck.

Hand-troweling looks easy until you try it. Creating that perfect 1/4 to 3/8-inch thickness over irregular surfaces takes years to master. We use specialized screeds and finishing tools that most homeowners don’t own.

Professional warranties provide peace of mind that DIY installations can’t match. When we install rubber surfacing for pool decks, both materials and workmanship are covered. DIY installations void most manufacturer warranties, leaving you holding the bag if problems develop.

More info about poured in place rubber pool deck

Rubber surfacing for pool decks installation timeline

The beauty of rubber surfacing for pool decks lies in how quickly you can transform your space. Most residential installations follow a predictable three-day schedule that gets you back to enjoying your pool fast.

Day 1 is all about preparation. We start early, power-washing the existing surface and letting it dry completely. Any significant cracks get filled with specialized repair compounds. Loose concrete gets chipped away, and oil stains receive treatment.

Day 2 brings the mixing and troweling magic. Weather has to cooperate—we need dry conditions and temperatures between 50-85°F. We set up our mixing station and start combining rubber granules with polyurethane binder in small batches. Each batch gets hand-troweled immediately to maintain workability.

Day 3 focuses on curing and final inspection. The surface needs 24-48 hours to reach full strength before foot traffic. We’ll do a final walkthrough, checking for any spots that need touch-ups. Light foot traffic is fine after 24 hours, but wait a full week before moving heavy furniture back onto the surface.

5. Maintenance, Repairs & Longevity Hacks

Here’s the beautiful truth about rubber surfacing for pool decks: it’s almost embarrassingly easy to maintain. While your neighbors are scrubbing, sealing, and constantly repairing their concrete or tile surfaces, you’ll be enjoying your pool instead of working on it.

Your regular maintenance routine is refreshingly simple. Hose off your deck with plain water to remove leaves, dirt, and debris. For deeper cleaning, just add some mild soap and give it a gentle scrub with a soft brush. That’s it. No harsh chemicals, no pressure washing that can damage the surface, and definitely no annual sealing marathons.

The real secret to getting your full 12-15 year lifespan is staying ahead of small issues before they become big problems. A monthly soap-and-water wash removes the body oils, sunscreen residue, and pool chemicals that can gradually dull the surface.

Here’s a pro tip: do the shuffle test every few months. Simply shuffle your feet across different areas of your deck. If rubber granules start coming loose easily, it’s time for rebinding—but don’t panic. This is normal maintenance that typically happens every 5-7 years, not a sign of failure.

Rebinding is like giving your deck a refresh. We apply a specialized rebinder that reattaches any loose granules and restores that like-new appearance. It’s much less expensive than replacement and can add years to your deck’s life.

When damage does happen—maybe a heavy planter fell over or a sharp object gouged the surface—repairs are surprisingly straightforward. Small holes can be patched with DIY kits that blend seamlessly with your existing surface. The key is acting quickly before water gets underneath and creates bigger problems.

More info about rubberized pool deck coating

Quick fixes when your rubber surface gets damaged

Don’t let minor damage to your rubber surfacing for pool decks stress you out. Most problems are easier to fix than you’d expect, especially if you catch them early.

Small holes (anything smaller than a quarter) are perfect candidates for DIY patch kits. The process is straightforward: clean the damaged area thoroughly, apply the patch material according to the instructions, and let it cure properly. The trick is acting fast—tiny holes have a way of becoming not-so-tiny if water starts getting underneath.

For loose granules, you’ll need rebinder. Here’s the math that matters: one 5-gallon pail covers about 1,500 square feet, so measure your deck area first. Apply rebinder on warm, dry days when the surface can cure properly.

Professional blend-in repairs are worth every penny for larger damage or spots in highly visible areas. We can match colors and textures so precisely that once everything cures, you’ll have trouble finding where the repair was made.

6. Design, Color & Eco-Friendly Credentials

The design possibilities with rubber surfacing for pool decks go far beyond basic safety improvements. We can create custom logos, intricate patterns, color transitions, and even incorporate different textures within the same installation.

Color blending opens up incredible creative possibilities. Standard colors can be mixed to create custom shades that perfectly complement your home’s exterior or landscape design. We’ve created everything from subtle earth tones that blend with natural surroundings to vibrant tropical colors that make pool areas pop.

Custom logos and graphics are popular for commercial installations but work great for residential properties too. Family crests, sports team logos, or decorative patterns can be integrated during installation using specialized stencils and color techniques.

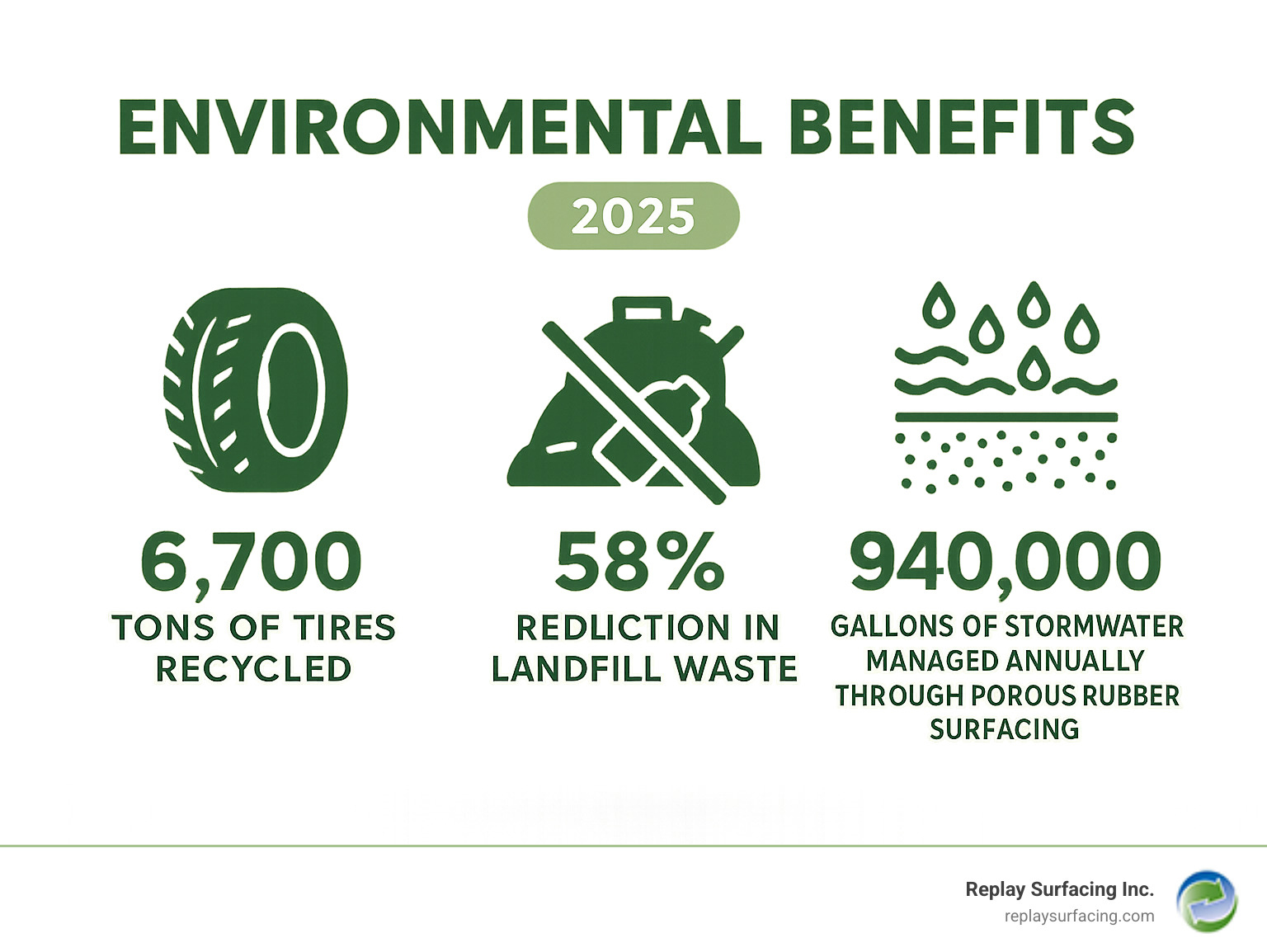

The eco-friendly credentials are impressive and getting better all the time. Most rubber surfacing is made primarily from recycled tires—we’re talking about diverting millions of pounds of waste from landfills and turning it into beautiful, functional surfaces.

LEED points are available for projects that incorporate recycled content and manage stormwater runoff. The porous nature of rubber surfacing allows water to drain through rather than running off into storm systems, helping with sustainable site development requirements.

More info about rubber epoxy pool deck

Turning recycled tires into rubber surfacing for pool decks

The sustainability story behind rubber surfacing for pool decks is compelling. Every square foot of surface incorporates rubber from multiple recycled tires that would otherwise sit in landfills for centuries.

At Replay Surfacing Inc., we’ve made tire recycling our specialty. The process involves shredding tires, removing steel and fabric components, and processing the rubber into granules sized specifically for surfacing applications. This isn’t just waste disposal—it’s genuine upcycling that creates a superior product.

The carbon footprint reduction is significant. Manufacturing new synthetic materials requires substantial energy inputs, while recycling existing rubber primarily involves mechanical processing. The transportation energy is minimal since tire waste is generated locally in every market.

Stormwater management benefits come from the porous structure that allows water to drain through rather than running off. This reduces strain on municipal storm systems and helps prevent erosion and flooding issues.

Frequently Asked Questions about Rubber Pool Deck Surfacing

Is rubber surfacing slip-resistant when wet?

This is probably the most common question we get, and I love answering it because rubber surfacing for pool decks actually gets more slip-resistant when wet. I know that sounds backwards, but think about it like your favorite rubber-soled sneakers—they grip better on wet pavement than dry.

The magic happens in two ways. First, the textured surface creates mechanical grip that your feet can hold onto, even when water is present. Second, the porous structure lets water drain right through instead of sitting on top like it does with concrete or tile.

We’ve had commercial pool facilities tell us their slip-and-fall incidents dropped by over 90% after switching to rubber surfacing. That’s not just a number—that’s families staying safe and having fun instead of dealing with injuries.

How much does it cost per square foot?

Professional poured-in-place rubber surfacing for pool decks runs about $16 per square foot in most markets. That includes everything—materials, expert installation, and our warranty coverage.

I’ll be honest: it’s more expensive upfront than basic concrete. But here’s the thing—concrete around pools is a maintenance nightmare. You’re sealing it every year, fixing cracks, dealing with hot spots that burn feet, and probably replacing it every 5-10 years.

With rubber surfacing, you hose it off occasionally and enjoy 12-15 years of comfortable, safe poolside living. When you break down the real costs over time, rubber often comes out ahead. Plus, you can’t put a price on not worrying about your kids slipping and getting hurt.

Can rubber surfacing help reduce slip-and-fall accidents around the pool?

Absolutely. Rubber’s textured and flexible surface provides enhanced traction when wet, significantly lowering the risk of slips and falls compared to harder deck options.

Is rubber surfacing suitable for both residential and commercial pool decks?

Yes. High-quality rubber surfacing is engineered for a wide range of pool environments, offering safety and durability whether it’s for a backyard retreat or a communal facility.

Can it be installed over cracked concrete?

Yes, absolutely! This is one of my favorite features of rubber surfacing for pool decks—it’s like giving your old, beat-up concrete a complete makeover without the demolition mess.

The flexible nature of rubber means it can bridge cracks up to 1/4 inch wide without any problems. When your concrete moves with temperature changes (and it will), the rubber moves with it instead of cracking like rigid materials do.

We’ve installed rubber surfacing over concrete, old tile, brick, even metal pool decks. The key is proper preparation—we clean everything thoroughly, fill any major holes, and make sure we have good adhesion. But you avoid the expense and disruption of jackhammering out your old deck.

It’s pretty amazing to see a cracked, dangerous concrete pool deck transform into a beautiful, safe surface in just a couple of days. No dumpsters, no weeks of construction chaos—just a complete change that performs better than brand-new concrete ever could.

Conclusion

Looking back at everything we’ve covered, rubber surfacing for pool decks really does check all the boxes. It’s safer than traditional materials, kinder to the environment, and honestly just makes pool time more enjoyable for everyone.

I’ve been in this business long enough to see the difference it makes when families can finally use their pool areas without worrying about kids slipping on wet concrete or burning their feet on scorching surfaces. There’s something really satisfying about taking what used to be a waste problem—millions of old tires—and turning them into surfaces that actually work better than brand-new traditional materials.

The numbers speak for themselves. Twelve to fifteen years of low-maintenance use, surfaces that stay cool even in blazing sun, and slip-resistance that actually improves when wet. Plus, you’re doing something good for the planet every time someone walks across your deck.

Whether your current concrete is cracked and dangerous, or you’re just tired of surfaces that become too hot to walk on, rubber surfacing offers a real solution. It’s not the cheapest option upfront, but when you factor in the longevity and performance, it often costs less than constantly repairing and replacing traditional materials.

At Replay Surfacing Inc., we’ve made it our mission to prove that sustainable doesn’t mean settling for less. In fact, it usually means getting something better. Your pool deck can be safer, more comfortable, and more beautiful while helping keep tires out of landfills.

Ready to make the switch? We’d love to talk about your specific situation and show you exactly how rubber surfacing can transform your outdoor space.