Why Rubber Coating for Concrete Pool Decks is Revolutionizing Commercial Facilities

Rubber coating for concrete pool decks offers facility managers a sustainable, slip-resistant solution that addresses safety concerns while reducing long-term maintenance costs. Here’s what commercial facilities need to know:

Key Benefits:

– Safety: Slip-resistant even when wet, shock-absorbing for fall protection

– Durability: 12-15 year lifespan with proper maintenance vs. 3-5 years for paint

– Cost: $9-16 per square foot installed, saves money through reduced repairs

– Environment: Made from recycled tires, low-VOC formulations

– Comfort: Up to 35% cooler than regular paint, barefoot-friendly surface

Popular Commercial Systems:

1. Poured-in-Place EPDM – Seamless, customizable colors ($16/sq ft)

2. Liquid Rubber Membranes – Brush/spray application, 20+ year potential

3. Rubberized Epoxy – 100% waterproof, textured for traction

4. Rubber Tiles – DIY-friendly, replaceable sections ($10/sq ft)

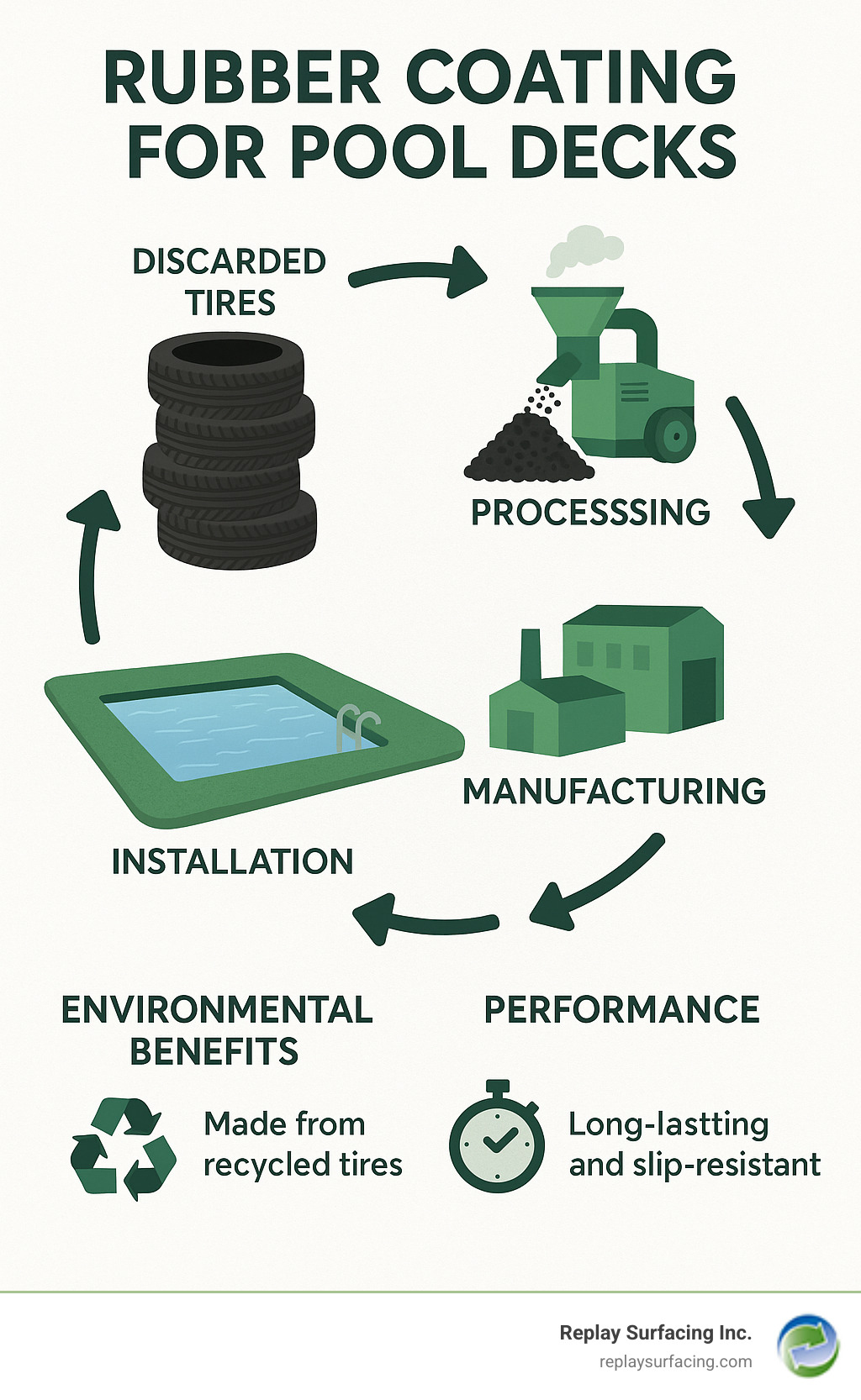

The change from environmental waste to high-performance surfacing makes rubber coatings an ideal choice for eco-conscious facilities. As one industry expert noted: “Rubber surfacing is 100% porous, allowing water to drain right through and reducing slip hazards” – a critical safety feature for pool environments.

I’m Landon Olson, a mechanical engineer with an MBA who specializes in sustainable surfacing solutions at Replay Surfacing Inc. My experience in manufacturing and recycling has shown me how rubber coating for concrete pool decks can transform both safety outcomes and environmental impact for commercial facilities.

Rubber coating for concrete pool decks terms simplified:

– rubber concrete

– custom color pool decks

– non slip pool deck surfaces

Why Choose Rubber Coating for Concrete Pool Decks

Picture managing a busy community pool and feeling stuck in a cycle of slip-and-fall incidents, scorching deck temperatures, and constant repainting. Rubber coating for concrete pool decks breaks that cycle by converting scrap tires into a cooler, safer, longer-lasting surface.

Compared with paint, which typically lasts 3-5 years, a well-maintained rubber system performs for 12-15 years. The material stays slip-resistant when wet, cushions falls, and remains up to 35 % cooler under direct sun. Its UV stability and chemical resistance protect against fading and chlorine damage, while the porous structure drains water to eliminate puddles.

The sustainability story is just as strong. Each installation diverts tires from landfills, and low-VOC binders keep indoor-air quality high. Add in the reduced energy needed to cool adjacent interior spaces and the lower maintenance spend, and the ROI quickly outweighs the higher upfront cost.

Safety & Comfort Improvements of rubber coating for concrete pool decks

- Non-slip texture that actually grips better when wet

- Built-in shock absorption for fall protection

- Barefoot-friendly surface that stays comfortable, not scorching

- Resistance to pool chemicals prevents rough, hazardous spots

Environmental & Cost Advantages of rubber coating for concrete pool decks

- Significant recycled-tire content, backed by scientific research

- Low-VOC formulations for healthier air

- Lower surface temperatures mean energy savings

- Long service life and quick, inexpensive touch-ups drive a favorable ROI

Comparing Commercial Rubber Coating Systems

Below is a streamlined look at the main options for rubber coating for concrete pool decks. All beat paint on service life and safety, but each offers its own balance of price, texture, and installation speed.

| System Type | Cost/Sq Ft | Expected Life | Install Time | Stand-Out Benefit |

|---|---|---|---|---|

| Poured-in-Place EPDM | $16 | 12-15 yr | 1-2 days | Seamless, custom colors |

| Liquid Rubber | $9-12 | 15-20 yr | Same day | Excellent waterproofing |

| Rubberized Epoxy | $12-15 | 10-12 yr | 1-2 days | 100 % waterproof & textured |

| Rubber Tiles | $10 | 8-12 yr | 1 day | DIY-friendly, replaceable |

| Traditional Paint | $3-5 | 3-5 yr | Same day | Low upfront cost only |

Poured-in-Place EPDM Surfacing

A custom blend of UV-stable granules and binder is mixed on-site, then hand-troweled into a seamless, joint-free sheet. Logos, borders, and multicolor patterns are easy to create, and routine topcoats can push life to 15 years.

More info about Poured in Place Rubber Pool Deck

Liquid Rubber Membranes

Applied with a roller, brush, or sprayer, these water-based coatings flex with concrete and seal hairline cracks. Glass-bead and reflective pigments can drop surface temps by up to 35 %. Recoat every few years for decades of use.

Rubberized Epoxy Overlays

Rubber granules embedded in a polyurethane matrix produce a durable, textured finish that’s fully waterproof—even on vertical faces like coping or steps. Ideal where chemical resistance is critical.

Interlocking & Tile Options

Pre-manufactured tiles click together quickly and can be swapped out one at a time. They cost less than poured systems but have seams that need a bit more cleaning attention.

Installation & Maintenance Best Practices

Getting rubber coating for concrete pool decks installed properly is like building a house – everything depends on having a solid foundation. After years of installations across our service areas in Charlotte NC, Columbia SC, and Raleigh NC, we’ve learned that the prep work makes or breaks the entire project.

Your concrete surface needs to be squeaky clean before we even think about applying coating. We start with a thorough power wash using specialized cleaners to remove dirt, oils, and any stubborn contaminants. Sometimes we need to etch the concrete surface to create the right texture for proper bonding.

Any existing coatings get a careful evaluation. If they’re compatible, great! If not, they need to come off completely. There’s no shortcut here – incompatible coatings will cause your new surface to fail.

Crack repair is absolutely critical and can’t be rushed. Even hairline cracks will telegraph through rubber coatings and eventually cause problems. We fill every crack with appropriate repair materials and let them cure completely.

Moisture testing prevents costly mistakes. Concrete might look dry on the surface but still be holding moisture underneath. We test moisture levels throughout the substrate and wait for readings to drop below manufacturer specifications.

Primer application depends on your specific substrate and coating system. Some surfaces need primer to ensure proper adhesion, while others are ready for direct coating.

DIY vs Professional Installation

Deciding whether to tackle rubber coating for concrete pool decks yourself or hire professionals comes down to honest assessment of your skills, tools, and time. We’ve seen both approaches work well, but we’ve also seen DIY projects that needed professional rescue.

Tool requirements vary dramatically between coating systems. Liquid rubber might only need brushes and rollers you already have, while poured-in-place systems require specialized mixing equipment, trowels, and safety gear.

Warranty considerations often tip the scales toward professional installation. Many manufacturers require certified installation to maintain warranty coverage. Think of professional installation as insurance – it protects your investment and gives you someone to call if problems arise.

The skill level needed goes beyond just following directions. Professional installers understand how weather affects curing, how to troubleshoot mixing problems, and how to achieve consistent results across large areas.

Downtime can be a deciding factor for commercial facilities. Our crews work efficiently and coordinate with your operational schedule. We understand that every day your pool area is out of service costs money, so we plan installations to minimize disruption.

Routine Care to Maximize Lifespan

Taking care of rubber coating for concrete pool decks isn’t complicated, but consistency matters. We’ve tracked the performance of our installations across different climates and maintenance schedules – the facilities that follow simple maintenance routines get significantly longer life from their surfaces.

Weekly sweeping removes debris before it can cause problems. Leaves, dirt, and organic matter can clog the porous surface and create slip hazards. Five minutes with a broom each week prevents hours of deep cleaning later.

Monthly power washing keeps surfaces looking fresh and performing properly. Use mild detergents to remove oils, sunscreen residues, and other contaminants that accumulate around pools. Avoid harsh chemicals or high-pressure settings that might damage the rubber surface.

Biannual topcoat maintenance is like changing the oil in your car – simple preventive care that extends life dramatically. Fresh topcoats refresh the protective layer and maintain surface flexibility. This maintenance costs a fraction of full replacement and can double your surface lifespan.

Spot repairs catch small problems before they become big headaches. Small tears or worn spots can be patched with compatible materials, preventing water infiltration that undermines the entire installation.

Winter care in northern climates focuses on drainage and chemical protection. Ensure water drains properly to prevent ice formation, and avoid deicing chemicals that can damage rubber. The flexibility of rubber coatings helps them survive freeze-thaw cycles, but proper drainage eliminates most winter-related problems.

Design & Color Customization

Creating beautiful rubber coating for concrete pool decks goes far beyond just picking a color from a chart. The design possibilities are honestly pretty exciting – we can transform what used to be boring concrete into stunning focal points that make people stop and take notice.

The magic happens with EPDM granules, which come in 12 or more decorative colors. But here’s where it gets interesting: we don’t just slap down one color and call it done. During installation, we can blend different colors right on site to create custom hues that match your facility’s exact needs. Want to match your school colors perfectly? We can do that. Need to complement your hotel’s branding? No problem.

Logo incorporation is where we really get to show off. Instead of dealing with separate signs that fade, crack, or need constant replacement, we can work your logo directly into the surface itself. The contrast between different colored rubber granules creates crisp, permanent designs that become part of the deck itself.

Pattern possibilities are limited only by imagination and skill. Our installers can create borders that define different areas, geometric designs that add visual interest, or even complex artistic elements that complement your facility’s architecture. The hand-troweled installation process gives us flexibility that pre-manufactured materials simply can’t match.

More info about Custom Color Pool Decks

Keeping Cool & Stylish

Let’s be honest – nobody wants to dance across a pool deck that’s hot enough to fry an egg. This is especially true in markets like Charlotte NC, Columbia SC, and Tucson AZ, where summer sun can turn traditional surfaces into foot-scorching hazards. Fortunately, modern rubber coating for concrete pool decks has some clever tricks to stay cool while looking great.

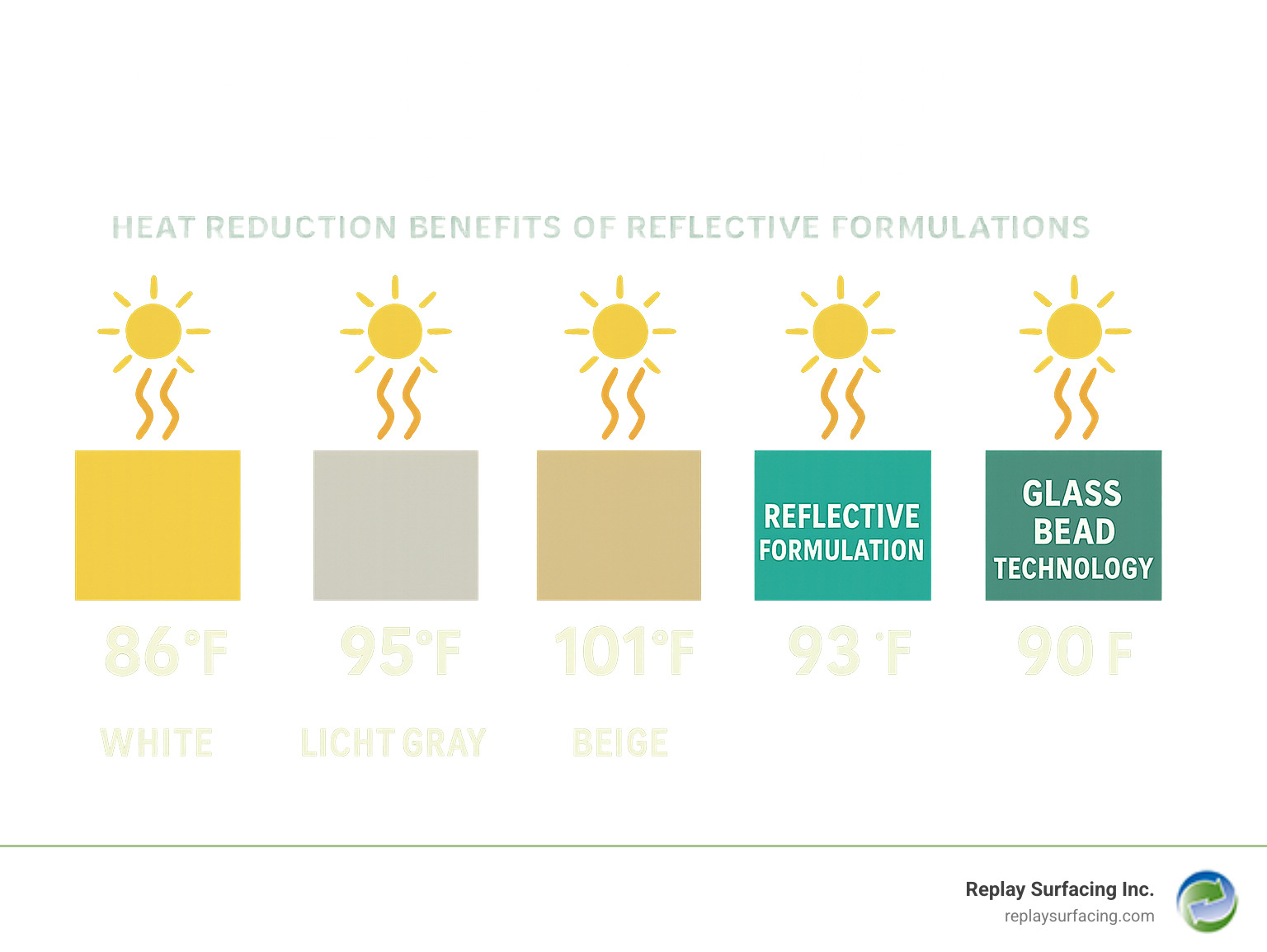

Heat-reflective pigments work like invisible sunglasses for your deck. These specialized pigments reflect solar energy instead of absorbing it as heat. The best part? They can be incorporated into any color, so you don’t have to sacrifice your design vision for comfort.

Glass bead technology takes heat reduction even further. Microscopic glass beads mixed into the surface coating create thousands of tiny reflective surfaces that bounce solar energy away from the deck. This isn’t just marketing hype – we’re talking about surface temperature reductions of up to 35% compared to conventional coatings.

Color selection still matters, though. Light colors like white, light gray, or beige naturally reflect more solar energy and stay cooler than darker options. But we understand that design requirements don’t always call for light colors. That’s exactly why reflective additives and glass bead technology become so valuable – they let you have your cake and eat it too.

Current aesthetic trends favor earth tones and natural colors that complement landscaping and architectural elements. The ability to create custom color blends means facilities can achieve these sophisticated looks while maintaining comfortable surface temperatures through smart pigment selection.

Frequently Asked Questions about Rubber Coating for Concrete Pool Decks

How much does installation cost per square foot?

When facility managers ask about rubber coating for concrete pool decks pricing, I always start by explaining that you’re making an investment, not just buying a coating. The upfront cost might seem higher than traditional paint, but the math changes completely when you factor in longevity and maintenance savings.

Poured-in-place EPDM systems run about $16 per square foot installed. Yes, that’s the premium option, but there’s a reason why so many of our commercial clients choose it. You get a seamless surface with unlimited color customization and that 12-15 year lifespan.

Liquid rubber membranes typically cost $9-12 per square foot. These systems offer excellent bang for your buck, especially if you need waterproofing along with slip resistance. The application is straightforward, which keeps labor costs down.

Rubberized epoxy systems fall right in the middle at $12-15 per square foot. You’re paying for that 100% waterproof protection and the textured surface that maintains traction even in the wettest conditions.

Rubber tile systems come in around $10 per square foot. The DIY-friendly installation and ability to replace individual sections make this an attractive option for facilities with maintenance teams who like to handle projects in-house.

Project size affects per-square-foot cost – bigger installations bring down your cost. We can spread fixed costs like mobilization and setup across more square footage. Also, if your existing concrete needs significant repair work, that’ll add to the total cost, but it’s necessary for a long-lasting installation.

How long does a rubberized deck really last?

This is probably the most important question you can ask about rubber coating for concrete pool decks. I’ve been in this business long enough to see installations from our early days still performing beautifully, and I can give you real-world numbers based on actual performance.

Poured-in-place EPDM systems consistently deliver that 12-15 year lifespan when maintained properly. The key word there is “maintained” – we’re talking about biannual topcoat applications and regular cleaning. The seamless installation means there are no weak spots where water can sneak in and cause problems.

Liquid rubber membranes can potentially give you 20+ years of service life. The secret is in the periodic recoating. Every few years, you refresh that protective layer, and the system just keeps going. It’s like giving your deck a mini-makeover that extends its life.

Rubberized epoxy systems typically provide 10-12 years of solid performance. The chemical resistance really shines in pool environments where chlorine and other chemicals would eat up traditional coatings. That textured surface keeps working throughout the system’s entire lifespan.

Rubber tile systems usually last 8-12 years, but here’s where they get interesting – you can replace individual tiles as needed. High-traffic areas might need attention before the rest of the deck, and you can handle those spot replacements without redoing everything.

The real lifespan killer isn’t time – it’s neglect. Regular sweeping, periodic power washing, and addressing small issues before they become big problems can push any system well beyond its typical projections.

Can rubber coating be applied over cracked or spalled concrete?

This question comes up on almost every site visit, and the answer is usually yes – but with some important caveats. Rubber coating for concrete pool decks can work over damaged concrete, but success depends entirely on proper preparation.

Minor cracks and surface imperfections are actually perfect candidates for rubber coating. The flexible nature of these materials means they can bridge small cracks without transmitting stress back to the coating. Poured-in-place systems are particularly good at this because we’re literally filling voids and smoothing out irregularities as we install.

Spalled concrete – where chunks have broken away – requires more work but can definitely be addressed. We remove all the loose material, fill the damaged areas with compatible repair compounds, and let everything cure properly before applying the coating. The key is using repair materials that play well with the coating system.

Structural damage or extensive cracking is where we might have a conversation about concrete replacement instead of coating. Our assessment process helps determine whether coating makes sense or if you need more extensive repairs.

The preparation work becomes more critical with damaged substrates. We’re talking thorough cleaning, proper crack filling, appropriate primers, and patience with curing times. It’s more work upfront, but it pays off with a coating that performs just as well as one applied over perfect concrete.

Conclusion

When we look at the complete picture, rubber coating for concrete pool decks offers something truly special for commercial facilities. It’s not just about creating a safer surface – though the slip resistance and shock absorption certainly deliver on that promise. It’s about making a choice that works better for everyone involved.

Rubber coating for concrete pool decks is more than just a surface upgrade. It represents a thoughtful investment in safety, comfort, sustainability, and long-term performance. By choosing a rubber-based system, you are addressing common pool deck challenges — from high surface temperatures and slippery conditions to frequent maintenance cycles — with a solution that performs better over time and enhances user experience.

At Replay Surfacing Inc., we’ve seen how changing discarded tires into high-performance pool deck surfaces creates win-win situations. Facilities get surfaces that stay cooler, last longer, and keep people safer. The environment benefits from keeping millions of tires out of landfills. And facility managers appreciate the long-term cost savings that come from surfaces lasting 12-15 years instead of needing replacement every few years.

The comfort factor really stands out when you experience these surfaces yourself. Walking barefoot on a surface that’s 35% cooler than regular paint makes a huge difference on hot summer days. The cushioning effect feels good underfoot while providing real protection if someone does slip or fall.

Environmental responsibility doesn’t have to mean compromising on performance. Our installations across Charlotte NC, Columbia SC, Raleigh NC, and other locations prove that recycled materials can outperform traditional options. When you choose rubber coating, you’re turning yesterday’s waste into tomorrow’s solution.

The design possibilities keep surprising people. Custom colors, logos, and patterns mean your pool deck can look exactly how you want it while delivering superior performance. Whether you need school colors for an aquatic center or corporate branding for a hotel pool, the customization options make it possible.

Cost considerations make sense when you look at the bigger picture. Yes, the initial investment runs higher than basic paint. But when you factor in the longer lifespan, reduced maintenance, and improved safety record, the numbers work in your favor. Most facilities see positive returns within just a few years.

Our experience across diverse climates – from the heat of Tucson AZ to the freeze-thaw cycles in Connecticut – has shown us that properly installed rubber coating for concrete pool decks consistently delivers on its promises. The key lies in choosing the right system for your specific situation and ensuring proper installation.

If you’re ready to explore how rubber coating can transform your pool deck, we’d love to help you evaluate your options. Every facility is different, and finding the right solution starts with understanding your specific needs, budget, and goals.