Why Playground Safety Starts from the Ground Up

Playground surfaces are the foundation of safe play, literally. They’re the materials installed beneath and around playground equipment to cushion falls and prevent serious injuries. Here’s what you need to know:

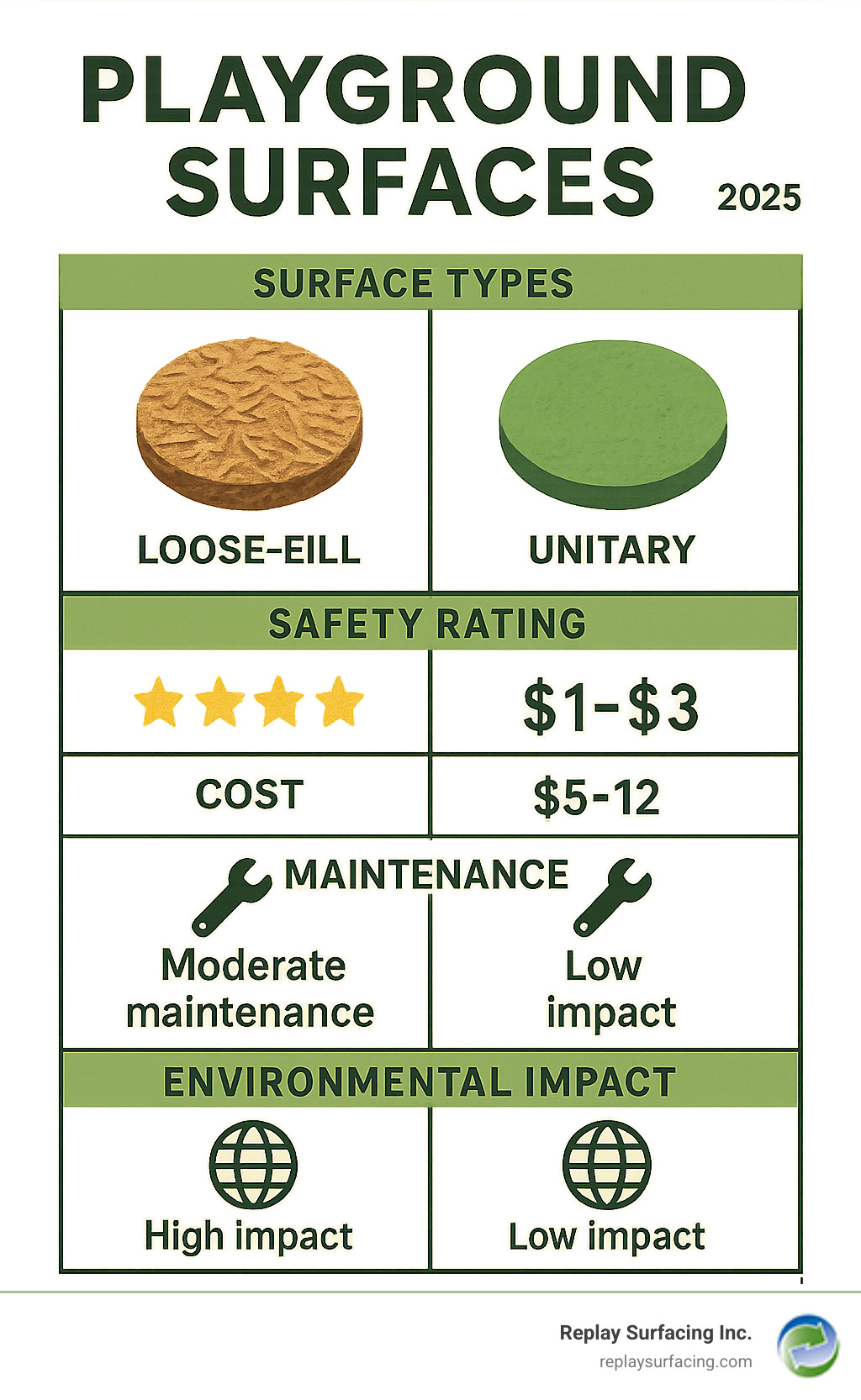

Main Types:

- Loose-fill surfaces – Wood fiber, rubber mulch, sand, pea gravel

- Unitary surfaces – Poured rubber, rubber tiles, synthetic turf

Key Safety Facts:

- Falls to playground surfaces cause 70% of all playground injuries

- Proper surfacing reduces life-threatening head injuries

- Materials must meet CPSC critical height standards

- Loose-fill needs 12+ inches depth to work effectively

Cost Range:

- Loose-fill: $1-$3 per square foot

- Unitary: $5-$12 per square foot

The stakes couldn’t be higher. As one parents’ group finded when they measured surface temperatures over 170°F on a 75°F day, the wrong surface choice can turn a fun afternoon into a dangerous situation.

Every playground surface decision impacts three critical areas: safety performance, long-term costs, and accessibility for all children. With over 205,000 kids visiting emergency rooms each year due to playground injuries, getting this right isn’t optional.

I’m Landon Olson, a mechanical engineer who’s spent years changing waste tires into safe, sustainable playground surfaces through my company Replay Surfacing. My experience in manufacturing and sustainability has shown me how the right playground surfaces can protect children while supporting environmental goals.

Common playground surfaces vocab:

Why Safe Surfacing Is Non-Negotiable

The numbers tell a sobering story. Falls to playground surfaces account for nearly 70% of all playground injuries, with 75% of all playground injuries occurring on improper or poorly maintained surfacing. That’s not just a statistic—it represents thousands of children who could have been protected with the right surface choice.

The Consumer Product Safety Commission (CPSC) requires that playground surfacing materials be tested for critical height, which is “an approximation of the fall height below which a life-threatening head injury would not be expected to occur.” This isn’t about preventing every scrape or bruise—it’s about preventing the kind of injuries that can change a child’s life forever.

Here’s what makes surfacing so critical:

Impact Absorption: When a child falls, three factors determine injury severity: the speed of the fall, the height of the fall, and the type of surface they land on. Proper surfacing can mean the difference between a minor bump and a serious head injury.

ASTM F1292 Standards: This standard specifies impact attenuation testing for playground surfaces, measuring g-forces and head injury criteria (HIC). Surfaces must meet these standards to be considered safe for playground use.

Accessibility Requirements: The Americans with Disabilities Act (ADA) requires that playground surfaces accommodate wheelchairs and mobility devices. This isn’t just about compliance—it’s about ensuring every child can play safely.

Scientific research on playground injuries shows that falling from heights over 8 feet can cause a concussion as serious as a 40 MPH car accident. That’s why proper surfacing isn’t optional—it’s essential.

Main Types of Playground Surfaces

Playground surfaces fall into two main categories, each with distinct characteristics that affect safety, cost, and maintenance:

Loose-Fill Surfaces are made of individual particles that create a cushioning layer through depth and displacement. These include:

- Engineered wood fiber (EWF)

- Rubber mulch

- Sand

- Pea gravel

Unitary Surfaces are installed as continuous, seamless systems that provide consistent cushioning across the entire play area:

- Poured-in-place rubber

- Rubber tiles

- Synthetic turf with safety padding

The choice between these categories often comes down to balancing upfront costs against long-term maintenance, accessibility needs, and aesthetic preferences.

Learn More about Safe and Durable options on our Rubber Flooring Playground Surfaces Page.

Loose-Fill Playground Surfaces: Pros & Cons

Loose-fill materials have been the traditional choice for playgrounds, and for good reason—they’re cost-effective and relatively easy to install. However, they come with specific maintenance requirements that must be understood upfront.

Engineered Wood Fiber (EWF) is the most popular loose-fill option. It’s made from wood that’s been processed to specific particle sizes and tested for hazardous elements like lead, chromium, cadmium, and arsenic. When properly compacted, EWF becomes ADA compliant by creating a relatively firm, even surface.

Pros of EWF:

- Lowest initial cost among safety surfaces

- Natural appearance that blends with outdoor settings

- ADA compliant when properly installed and maintained

- Good shock absorption when maintained at proper depth

Cons of EWF:

- Requires regular raking and replenishment

- Can harbor mold and decompose unevenly

- Displacement under swings and slides creates unsafe low spots

- May contain splinters or attract insects

Rubber Mulch, often Called Playground Safe Much is made from recycled tires, making it an eco-friendly option that resists mold and mildew better than wood fiber.

Pros of Rubber Mulch:

- Excellent shock absorption

- Doesn’t decompose or attract insects

- Made from 100% recycled materials

- Maintains cushioning properties longer than wood fiber

Cons of Rubber Mulch:

- Higher cost than wood fiber

- Can retain heat in direct sunlight

- May track onto shoes and clothing

- Requires periodic cleaning to remove debris

Sand and Pea Gravel are traditional materials that are no longer recommended for commercial playgrounds. The ADA Standards for Accessible Design eliminated sand and pea gravel from commercial playground use because they don’t provide adequate wheelchair accessibility.

Critical Maintenance Factor: All loose-fill materials compress at least 25% over time due to use and weathering. This compression must be accounted for in initial installation depth, and materials must be replenished regularly to maintain safety standards.

For detailed guidance on loose-fill options, visit our Loose Fill Playground Surfacing page.

Unitary Playground Surfaces: Pros & Cons

Unitary surfaces represent the modern approach to playground safety, offering seamless protection and improved accessibility. While they require higher upfront investment, they often prove more cost-effective over time.

Poured-in-Place Rubber is installed as a two-layer system with a shock-absorbing base layer covered by a granular finish layer. This system offers virtually unlimited design possibilities and can be customized with colors, patterns, and graphics.

Pros of Poured-in-Place Rubber:

- Excellent impact attenuation for all fall heights

- Seamless surface provides full wheelchair accessibility

- Customizable with colors, patterns, and educational graphics

- Long lifespan (10-15 years with proper maintenance)

- Doesn’t require depth replenishment

Cons of Poured-in-Place Rubber:

- Higher initial installation cost

- Can become very hot in direct sunlight

- Requires professional installation

- May crack over time, especially in freeze-thaw climates

Rubber Tiles offer a modular approach that combines many benefits of poured rubber with easier installation and repair options.

Pros of Rubber Tiles:

- Individual tiles can be replaced as needed

- DIY installation possible for some systems

- Good impact protection when properly installed

- Available in various colors and patterns

Cons of Rubber Tiles:

- Seams can create tripping hazards if not properly maintained

- May shift over time without proper edging

- Hardware deterioration can occur before material wear

Synthetic Turf with safety padding underneath provides an appealing aesthetic while meeting safety requirements.

Pros of Synthetic Turf:

- Attractive, grass-like appearance

- Excellent drainage after rain

- Low maintenance once installed

- Can incorporate antimicrobial layers

Cons of Synthetic Turf:

- Requires safety padding underneath to meet fall-height requirements

- Can retain heat in hot climates

- Higher cost than traditional loose-fill options

At Replay Surfacing, we specialize in changing waste tires into these durable, sustainable surfaces. Our Poured-in-Place Rubber: The Ultimate Playground Safety Surface provides detailed information on our installation process and customization options.

Comparing Safety, Accessibility & Sustainability

When evaluating playground surfaces, three key factors determine long-term success: safety performance, accessibility compliance, and environmental impact.

Safety Performance is measured through impact attenuation testing, which determines how well a surface absorbs the energy of a fall. The Consumer Product Safety Commission’s critical height testing estimates fall heights below which life-threatening head injuries are unlikely to occur.

Accessibility Standards under the Americans with Disabilities Act require surfaces to accommodate wheelchairs and mobility devices. Scientific research on accessibility standards shows that firm, stable surfaces significantly improve access for children with disabilities.

Environmental Considerations include heat retention, chemical exposure, and recyclability. Some surfaces can reach dangerous temperatures—as documented when a poured-in-place surface measured over 170°F on a 75°F day.

Here’s how different surfaces compare:

| Surface Type | Safety Rating | Accessibility | Heat Retention | Environmental Impact |

|---|---|---|---|---|

| Engineered Wood Fiber | Good (with depth) | Moderate | Low | Biodegradable |

| Rubber Mulch | Excellent | Moderate | High | Recycled content |

| Poured Rubber | Excellent | Excellent | High | Recycled content |

| Rubber Tiles | Good to Excellent | Good | Moderate | Recycled content |

| Synthetic Turf | Good (with padding) | Excellent | Moderate | Mixed materials |

Heat Retention is a critical safety factor often overlooked. Rubber surfaces can become uncomfortably hot, potentially causing burns. Cool-reflect technology and proper color selection can help mitigate this issue.

Chemical Exposure concerns have emerged with some rubber surfaces. Testing has found liftd levels of lead and other chemicals on some playground surfaces, making it important to verify that materials meet safety standards.

Recycled Content makes rubber surfaces environmentally beneficial by diverting waste tires from landfills. At Replay Surfacing, we use recycled rubber from U.S. sources only, ensuring quality control while supporting local recycling programs.

Budgeting & Maintenance for Long-Term Performance

Understanding the total cost of ownership is crucial for making informed decisions about playground surfaces. Initial installation cost is just the beginning—maintenance, replacement, and lifecycle costs often exceed the original investment.

Initial Installation Costs:

- Loose-fill materials: $1-$3 per square foot

- Unitary surfaces: $5-$12 per square foot

- Site preparation and drainage: Additional $2-$5 per square foot

Long-term Maintenance Costs:

- Loose-fill surfaces require regular replenishment, typically 20-25% of material annually

- Unitary surfaces need periodic cleaning and minor repairs

- Professional inspections should be conducted annually

Maintenance Schedules:

Daily/Weekly:

- Visual inspection for hazards

- Removal of debris and foreign objects

- Raking of loose-fill materials in high-traffic areas

Monthly:

- Depth measurement of loose-fill materials

- Cleaning of unitary surfaces

- Inspection of drainage systems

Annually:

- Professional safety inspection

- Impact attenuation testing

- Major repairs or surface replacement as needed

Lifespan Expectations:

- Engineered wood fiber: 3-5 years before major replenishment

- Rubber mulch: 5-8 years with proper maintenance

- Poured-in-place rubber: 10-15 years with proper care

- Rubber tiles: 8-12 years under average use

Warranty Considerations:

Most manufacturers offer warranties ranging from 1-10 years, but these typically cover material defects rather than normal wear. Understanding warranty terms helps set realistic expectations for replacement timing.

For detailed cost analysis, visit our Understanding Rubber Playground Surfacing Costs page.

How to Choose the Best Playground Surface for Your Site

Selecting the right playground surfaces requires evaluating multiple factors specific to your site, users, and budget. There’s no one-size-fits-all solution, but following a systematic approach ensures you make the best choice for your specific needs.

Equipment Height Assessment:

The maximum fall height of your playground equipment determines the required impact attenuation of your surface. Higher structures require either deeper loose-fill materials or higher-performance unitary surfaces.

User Age Group Considerations:

- Ages 2-5: Avoid loose-fill materials that could become choking hazards

- Ages 5-12: All surface types appropriate with proper installation

- Mixed age groups: Consider zoning different surfaces for different areas

Climate and Drainage Factors:

- High rainfall areas: Prioritize drainage and quick-drying surfaces

- Hot climates: Avoid dark-colored surfaces that retain heat

- Freeze-thaw cycles: Choose materials that won’t crack or heave

Inclusive Design Principles:

Designing for accessibility benefits all children, not just those with disabilities. Firm, stable surfaces allow wheelchair users to access play areas while providing stable footing for all children.

Budget Allocation:

Consider both initial costs and long-term maintenance when budgeting. A surface that costs twice as much initially but lasts three times longer may be the better investment.

Avoiding Toxic Materials:

Some materials should be avoided entirely:

- Chromated copper arsenate (CCA) treated wood

- Surfaces with high lead content

- Materials that haven’t been tested for hazardous elements

Professional Consultation:

Always consult with a Certified Playground Safety Inspector when making surfacing decisions. The right or wrong choice could make a significant difference in child safety.

For comprehensive guidance on shock-absorbing options, visit our Shock Absorbing Playground Surfaces page, and reference Americans with Disabilities Act guidelines for accessibility requirements.

Designing for Inclusive & Sensory Play

Modern playground design goes beyond basic safety to create environments that engage all children’s senses and abilities. Playground surfaces can be designed to support inclusive and sensory play through thoughtful material selection and layout.

Color Contrast and Visual Design:

High-contrast colors help children with visual impairments steer play areas safely. Poured-in-place rubber allows for custom graphics, educational elements, and wayfinding systems to be integrated directly into the surface.

Tactile Pathways:

Different surface textures provide tactile feedback that helps children with visual impairments steer independently. Smooth pathways can connect different play zones while textured areas signal transitions or activity zones.

Sensory Integration:

Combining different surface types within a single playground creates sensory transitions that support child development. Moving from a firm rubber surface to loose-fill materials provides different tactile experiences.

Universal Design Principles:

Surfaces designed for accessibility benefit all users. Firm, stable surfaces make it easier for children to run, ride bikes, or use mobility devices while providing stable footing for adults supervising play.

Frequently Asked Questions About Playground Surfaces

What is the safest playground surface?

The safest playground surface depends on proper installation and maintenance rather than material type alone. However, poured-in-place rubber consistently rates highest for safety due to its excellent impact attenuation, seamless surface, and ability to meet all fall-height requirements.

Engineered wood fiber, when properly installed and maintained at 12+ inches depth, provides excellent safety at a lower cost but requires more ongoing maintenance.

Which playground surface needs the least maintenance?

Unitary surfaces like rubber tiles or poured rubber need the least upkeep.

Are playground surfaces safe in hot weather?

Yes, when light colors and proper materials are used to reduce heat.

How much does playground surfacing cost per square foot?

Playground surfacing costs vary significantly based on material type and site conditions:

Loose-Fill Materials:

- Engineered wood fiber: $1-$2 per square foot

- Rubber mulch: $2-$3 per square foot

- Plus installation labor: $1-$2 per square foot

Unitary Surfaces:

- Rubber tiles: $4-$8 per square foot installed

- Poured-in-place rubber: $6-$12 per square foot installed

- Synthetic turf with padding: $8-$15 per square foot installed

Site preparation, drainage, and accessibility features can add $2-$5 per square foot to any installation.

How deep should loose-fill surfacing be?

Loose-fill surfacing should be installed at a minimum depth of 12 inches under and around playground equipment. However, since loose-fill materials compress at least 25% over time, initial installation depth should be 15-16 inches to maintain the required 12-inch minimum after settling.

The specific depth requirement depends on the maximum fall height of your equipment and the type of loose-fill material used. Higher structures may require deeper surfacing or alternative unitary surfaces.

Conclusion

Choosing the right playground surfaces is one of the most important decisions you’ll make for your play space. With 70% of playground injuries resulting from falls to surfaces, and over 205,000 children visiting emergency rooms annually due to playground injuries, the stakes are simply too high to leave this decision to chance.

Choosing the right playground surfaces is about protecting children today and avoiding costly fixes tomorrow. The right material improves safety, accessibility, and long-term value for any play space. At Replay Surfacing, we help schools, parks, and communities select playground surfaces that meet safety standards, fit budgets, and perform reliably year after year.

At Replay Surfacing, we’ve built our business on changing environmental hazards—waste tires—into sustainable, customizable, and durable surfaces that protect children while supporting environmental goals. Our locations across Charlotte NC, Columbia SC, Raleigh NC, Sanford NC, Tucson AZ, Connecticut, Indiana, Nashville TN, Beaverton OR, and Lake Charles Louisiana allow us to serve communities nationwide with expert installation and ongoing support.

Whether you choose loose-fill materials for their natural appearance and lower initial cost, or unitary surfaces for their accessibility and low maintenance, the key is understanding your specific needs and making an informed decision based on safety, accessibility, sustainability, and long-term value.

Proper installation and ongoing maintenance are just as important as material selection. Regular inspections, depth monitoring for loose-fill materials, and professional safety assessments ensure your playground surface continues to protect children throughout its lifespan.

Ready to create a safe, sustainable play environment for your community? Visit our Playground Surfacing page to learn more about our comprehensive solutions and get expert guidance for your specific project needs.

The ground rules for fun are simple: choose surfaces that prioritize safety, support accessibility, and sustain long-term performance. With the right surface choice, you’re not just creating a playground—you’re creating a foundation for safe, inclusive play that will serve your community for years to come.