Why a DIY Rubber Pool Deck in Charlotte is the Smart Choice for Your Home

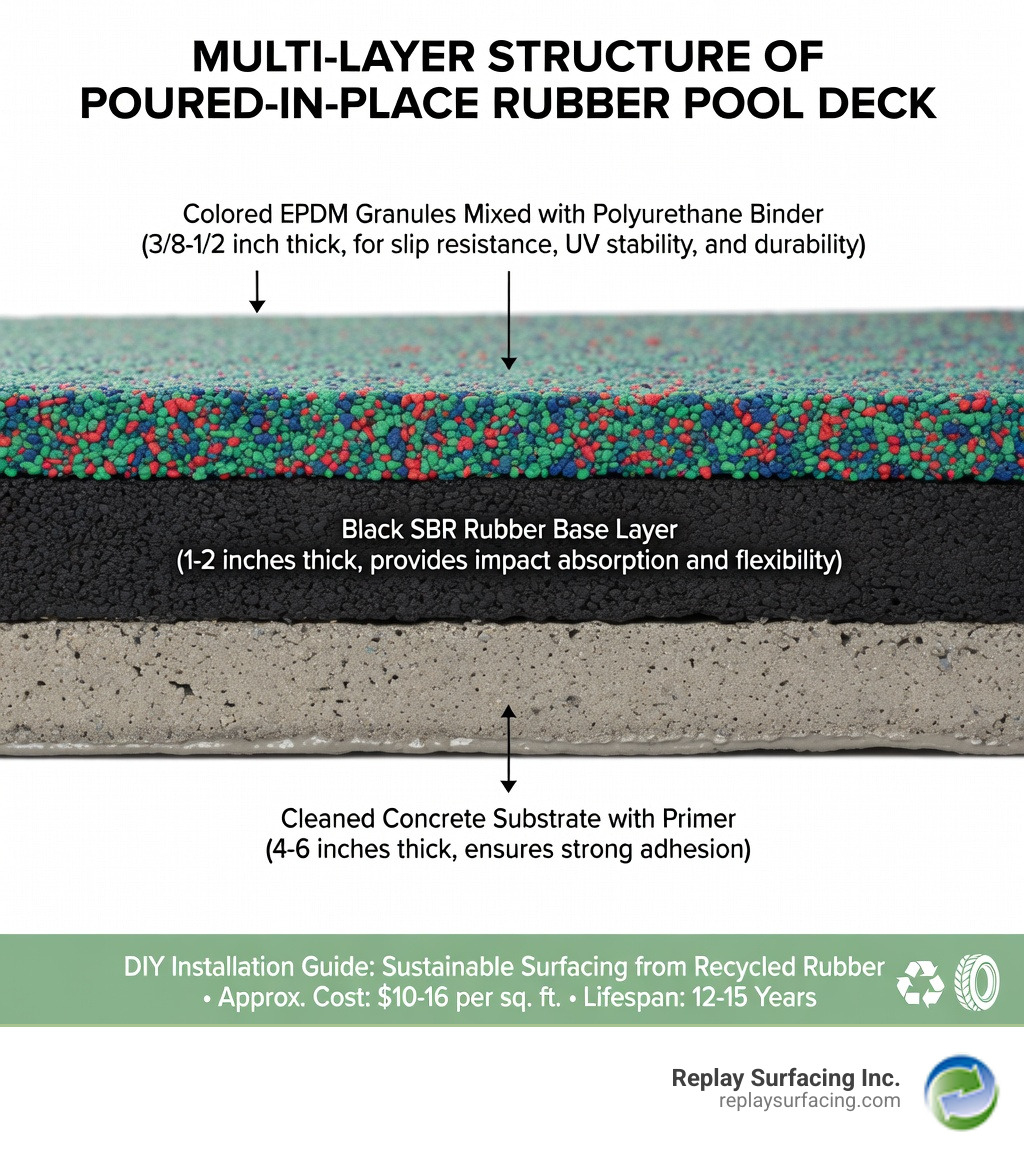

A diy rubber pool deck in Charlotte transforms your old concrete or cracked pool deck into a safe, cool, slip-resistant surface using recycled rubber granules bonded with polyurethane. Here’s what you need to know to get started:

Quick Overview: DIY Rubber Pool Deck Installation

- Materials Needed: EPDM or TPV rubber granules, polyurethane binder (aromatic or aliphatic), primer, trowel, and mixing tools

- Surface Prep: Pressure wash, repair cracks, apply primer to ensure proper adhesion

- Mixing Ratio: 1 gallon of binder per 44.4 pounds of rubber granules

- Application: Pour and hand-trowel the mixture to 1/4 inch thickness within 30-40 minutes working time

- Curing Time: Allow 48-72 hours to dry completely before use

- Cost: Approximately $10-16 per square foot for DIY materials (vs. professional installation)

- Lifespan: 12-15 years with proper maintenance including rebinding every few years

If you’ve ever walked barefoot on scorching concrete around your pool in the middle of a Charlotte or Columbia summer, you know the pain. Traditional concrete absorbs and radiates heat, reaching temperatures that can literally burn your feet. Meanwhile, that same concrete becomes slippery when wet and cracks over time from freeze-thaw cycles—even in milder climates like West Nashville.

Rubber pool decking solves all three problems. It stays cooler underfoot thanks to rubber’s higher specific heat capacity (2.01 kJ/kg·K compared to concrete’s 0.75 kJ/kg·K), provides natural slip resistance when wet, and flexes with temperature changes instead of cracking. Plus, it creates a softer landing surface that’s easier on joints and safer for kids running around the pool.

The best part? You can install it yourself over your existing concrete deck without needing specialized equipment or hiring expensive contractors. While professional poured-in-place rubber installations offer seamless results, a well-executed DIY project using quality materials can deliver similar benefits at a fraction of the cost.

I’m Landon Olson, operator of Replay Surfacing, where we’ve recycled millions of pounds of scrap tires into sustainable surfacing solutions across Charlotte, Columbia, and West Nashville. Over the years, I’ve helped countless homeowners and facility managers understand the ins and outs of diy rubber pool deck in Charlotte installations, from selecting the right materials to avoiding common mistakes that lead to premature failure.

Basic diy rubber pool deck in Charlotte glossary:

Understanding Rubber Pool Deck Surfacing and Materials

When we talk about a diy rubber pool deck in Charlotte, we aren’t just talking about laying down a few mats. We are talking about a sophisticated poured in place rubber pool deck system. This surfacing consists of synthetic rubber granules—either EPDM or TPV—mixed with a high-strength polyurethane binder. This mixture is hand-troweled directly onto your existing substrate, whether that’s old concrete, wood, or even tile.

The materials you choose will dictate how your deck looks and feels five years from now. Many DIYers start by looking at rubber pool decking surfaces to understand the texture. The granules are the “meat” of the system, while the binder acts as the “glue.” If you use low-quality binder or the wrong type of granule, your deck might fade or start “granulating” (losing little bits of rubber) much sooner than it should.

According to research on rubber material properties, the quality of the polymer content in the rubber is vital for durability. At Replay Surfacing, we prioritize materials that can withstand the intense UV rays found in Tucson, AZ, and the humidity of Lake Charles, Louisiana.

Choosing Between EPDM and TPV Granules

In rubberized pool deck coating, you’ll likely encounter two main types of granules: EPDM (Ethylene Propylene Diene Monomer) and TPV (Thermoplastic Vulcanizates).

- EPDM: This is the industry standard. It’s a synthetic rubber known for its weather resistance. However, EPDM can sometimes vary in polymer content; higher polymer content means better durability.

- TPV: Many experts now consider TPV the superior choice. It offers better color retention and UV stability than standard EPDM. For homeowners in Charlotte, NC, or Columbia, SC, where the sun beats down relentlessly, TPV is often worth the slight price premium to ensure your vibrant colors don’t wash out.

The Role of Aromatic vs. Aliphatic Binders

The binder is the unsung hero of your diy rubber pool deck in Charlotte. There are two primary types of polyurethane binders:

- Aromatic Binder: This is the more affordable option. It is incredibly strong but has one major drawback: it reacts with UV light and will “amber” or turn slightly yellow over time. If you are using earth tones (browns, tans, reds), this might not be an issue.

- Aliphatic Binder: This is a “non-yellowing” binder. It stays clear even under direct sunlight. If you are choosing cool blues, grays, or whites for your rubber deck coating, aliphatic is a must.

In climates like West Nashville, TN, or Sanford, NC, where humidity can affect the curing process, choosing a high-quality, moisture-cured binder ensures the structural integrity of your deck for years to come.

The Benefits of a DIY Rubber Pool Deck

Why go through the effort of a DIY installation? The benefits go far beyond just saving a few bucks on labor. A rubber surface is fundamentally different from a hard masonry surface. It is porous, flexible, and forgiving.

One of the biggest draws is the non-slip pool deck surfaces that rubber provides. Even when the kids are splashing water everywhere, the texture of the rubber granules provides excellent traction. Additionally, rubber acts as a shock absorber. If someone does take a tumble, falling on rubber is significantly safer than hitting hard concrete or pavers.

| Feature | Rubber Pool Decking | Traditional Concrete |

|---|---|---|

| Slip Resistance | Excellent (Wet or Dry) | Poor when wet |

| Surface Temp | Stays Cool (High Heat Capacity) | Very Hot (Low Heat Capacity) |

| Flexibility | High (Resists Cracking) | None (Prone to Cracking) |

| Comfort | Soft and Impact-Absorbing | Hard and Unforgiving |

| Maintenance | Easy (Power wash/Rebind) | Difficult (Sealing/Patching) |

Cool Underfoot: Specific Heat Capacity Explained

We often hear that rubber is “cooler,” but there is actual science behind it. Rubber has a specific heat capacity of 2.01 kJ/kg.K, while concrete sits at a lowly 0.75 kJ/kg.K. In simple terms, this means rubber requires much more energy to raise its temperature.

For our friends in Charlotte, Columbia, and Nashville, this is a game-changer. While a concrete rubber pool deck might reach 120°F in the July sun, a rubber surface will remain comfortable for bare feet. This thermal comfort, combined with high solar reflectance in lighter colors, makes your pool area usable even during the hottest parts of the day.

Safety and Impact Protection

Safety is usually the number one reason parents look into rubber surfacing for pool decks. Poured rubber is ADA-compliant, meaning it’s easy for wheelchairs to steer, and it provides a “buoyant” feel that reduces impact on joints.

In many commercial settings, this same material is used to protect against falls from 10-12 feet. While your pool deck won’t be that thick (usually 1/4″ to 1/2″), the natural cushioning of the rubber provides a layer of protection that concrete simply cannot match.

Step-by-Step Guide to Your DIY Rubber Pool Deck Installation

Ready to get your hands dirty? A diy rubber pool deck in Charlotte project is a manageable weekend task for a motivated homeowner. You don’t need a degree in engineering—just some patience and a good trowel hand.

Preparing Your Surface for a DIY Rubber Pool Deck

You can’t build a great house on a bad foundation, and you can’t install a great rubber coating for concrete pool decks on a dirty surface.

- Pressure Wash: Use a high-pressure washer to remove all dirt, algae, and loose debris. The concrete must be “open” and porous to accept the binder.

- Dry Completely: This is critical. Polyurethane binder reacts with moisture. If the concrete is damp, the binder will foam up and fail.

- Repair Cracks: Use a rubber epoxy pool deck patch or a standard concrete filler for large cracks. Small “spider” cracks are usually fine, as the rubber will bridge over them.

- Primer: Apply a thin coat of pure binder (or a specialized primer) to the surface. This creates a “tack coat” that ensures the rubber sticks to the concrete. In humid climates like Lake Charles or Raleigh, NC, ensure the primer doesn’t sit too long before you start pouring the rubber.

Mixing and Applying the Rubber Granules

Once your surface is prepped, it’s time to mix. The standard ratio is 1 gallon of binder per 44.4 lb bag of EPDM granules.

- The Mix: Use a heavy-duty drill with a “Magic Whip” or mixing paddle. Mix for 3-5 minutes until every granule is thoroughly coated in binder. It should look wet and glistening.

- The Clock: You have about a 30-minute working time. In the heat of a Tucson, AZ summer, this window might be even shorter. Work in small sections (about 15-25 sq ft at a time).

- The Trowel: Pour the mixture out and spread it to your desired thickness (typically 1/4″ to 3/8″). Use a pool trowel to smooth it out. Pro Tip: Keep your trowel lubricated with a little soapy water or a specialized trowel lubricant. This prevents the rubber from sticking to the tool and allows you to get a “tight,” smooth finish.

If you are looking for a more “natural” look, you might want to check out our rubber stone pool deck guide.

Maintenance and Longevity of Your Rubber Surface

One of the best things about a rubber pool deck resurfacing project is how easy it is to maintain. Unlike wood that needs staining or concrete that needs sealing, rubber just needs a good cleaning now and then.

For weekly maintenance, a leaf blower is your best friend. It removes debris from the tiny crevices between granules. Twice a year, give it a deeper clean with a mild soap solution and a low-pressure power wash. This prevents mold and algae from taking root in the porous surface—a common concern in humid areas like Raleigh or Sanford, NC.

The Rebinding Process

Over time, UV rays and foot traffic will wear down the binder on the very top of the granules. To extend the life of your deck to that 12-15 year mark, you should perform a “rebinding” every 2-3 years.

This involves rolling on a fresh coat of rubberized deck coating (topcoat).

- The Shuffle Test: If you can scuff your foot across the deck and granules pop loose, it’s time to rebind.

- Coverage: A 5-gallon pail of Rebinder typically covers about 1500 square feet.

- Application: Simply blow off the deck, ensure it’s dry, and use a paint roller to apply a thin, even coat. This “glues” everything back together and refreshes the color.

Repairing Small Holes and Cracks

If a heavy piece of furniture or a sharp object gouges your deck, don’t panic. One of the perks of a poured surface is that it’s easily patchable. You can use a small rubber tiles pool deck guide to see how different textures interact, or simply buy a small patch kit. You mix a tiny amount of granules and binder, trowel it into the hole, and it blends seamlessly with the existing surface.

Frequently Asked Questions about DIY Rubber Pool Decks

Is a DIY rubber pool deck in Charlotte suitable for cold climates?

Absolutely. In fact, rubber is often better for cold climates like West Nashville, TN, or Beaverton, OR, than concrete. Because the surface is composed of individual granules held together by flexible polyurethane, it can expand and contract during freeze-thaw cycles without cracking. It acts like a giant “expansion joint” for your entire pool area. For more on the latest tech, see best rubber pool decks 2026.

How much does a DIY rubber pool deck in Charlotte cost per square foot?

When you choose the DIY route, you are essentially cutting the rubber pool deck cost in half.

- DIY Materials: Usually range from $10 to $16 per square foot, depending on whether you choose EPDM or TPV and the type of binder.

- Professional Install: Can range from $18 to $25+ per square foot.

By doing the labor yourself, a 500-square-foot deck could save you upwards of $4,000.

How long does a rubber pool deck last?

With proper care, a rubber pool deck resurfacing project should last 12 to 15 years. Many professional materials come with a 10-year guarantee. The key to longevity is that 2-3 year rebinding schedule and keeping the surface clean of organic debris that can trap moisture. In the Southeast, where we deal with high UV and high humidity, the quality of your initial binder choice is the biggest factor in how long the deck lasts.

Conclusion

Taking on a diy rubber pool deck in Charlotte project is one of the most rewarding ways to upgrade your home’s outdoor space. Not only are you creating a safer, cooler, and more beautiful environment for your family, but you’re also supporting sustainability. At Replay Surfacing Inc., we are proud to transform environmental hazards—like old tires—into the durable, high-performance surfaces you see around pools in Charlotte, NC, Columbia, SC, and beyond.

Whether you’re in the desert heat of Tucson or the rainy suburbs of Beaverton, rubber surfacing offers a level of comfort and durability that traditional concrete just can’t match. If you’re ready to stop burning your feet and start enjoying your pool again, it’s time to get your hands dirty.

Transform your outdoor space with professional-grade rubber surfacing and see the difference that quality materials can make. From Raleigh to Nashville, we’re here to help you build a deck that lasts.