Why EPDM Wet Pour Rubber Surfacing in Charlotte is the Top Choice for Playgrounds

EPDM wet pour rubber surfacing in Charlotte is a poured-in-place safety surface made from two layers: a shock-absorbing base of recycled tire rubber (SBR) and a colorful, durable top layer of EPDM granules, all bound together with polyurethane resin. Here’s what you need to know:

Key Features:

- Two-layer system: SBR base (recycled tires) + EPDM top (virgin rubber granules)

- Safety-tested: Meets critical fall heights up to 10-13 feet per ASTM F1292

- Lifespan: 10-15 years with basic maintenance

- Eco-friendly: 82-96% recycled content

- Seamless & porous: No trip hazards, quick drainage

- Customizable: Available in 15+ colors with custom designs

Whether you’re managing a school playground in Charlotte, a splash pad in Lake Charles, or a community park in Nashville, understanding rubber surfacing helps you choose wisely for safety, durability, and your budget. EPDM wet pour stands out because it’s installed on-site as a liquid, creating a seamless surface that absorbs falls, drains water, and lasts over a decade with proper care.

As Landon Olson, operator of Replay Surfacing, I’ve applied my engineering background to transform millions of pounds of scrap tires into sustainable EPDM wet pour rubber surfacing. I’ve seen how these materials perform in real-world conditions across our service regions—from the intense sun in Tucson to the varied weather in Raleigh.

What is EPDM Wet Pour Rubber Surfacing and How Is It Made?

EPDM wet pour rubber surfacing is the gold standard for safety and aesthetics in playgrounds and recreational spaces. It’s a carefully engineered system designed to protect, perform, and please the eye.

This innovative surfacing is mixed and troweled on-site, creating a continuous, joint-free layer that eliminates trip hazards. Its porous structure ensures excellent drainage, so the surface is ready for use year-round, even after heavy rain. We deliver top-tier Poured-in-Place Rubber: The Ultimate Playground Safety Surface solutions across our service areas, from the busy playgrounds of Charlotte to community spaces in Tucson, ensuring every project meets the highest standards.

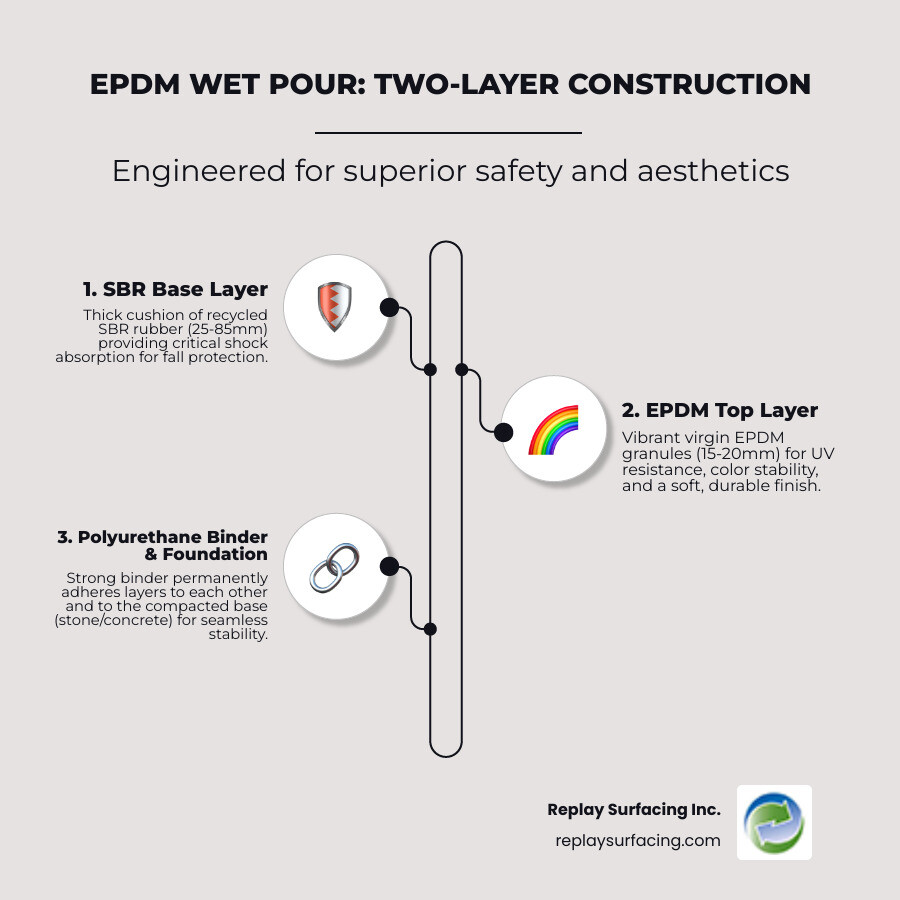

The Two-Layer Construction Explained

The performance of EPDM wet pour rubber surfacing comes from its two-layer construction:

- The Base Layer (Shock Absorption): This foundational layer is made of Styrene Butadiene Rubber (SBR) granules, sourced from recycled tires. Laid at depths from 25mm to 85mm, its primary function is shock absorption, providing the necessary cushioning to meet the Critical Fall Height (CFH) of play equipment. This is the core of the system’s safety, as detailed in our guide to Shock Absorbing Playground Surfaces.

- The Top Layer (Durability and Design): This visible, 15-20mm thick layer is made from virgin Ethylene Propylene Diene Monomer (EPDM) rubber granules. Applied over the SBR base, it provides:

- UV Resistance: EPDM is highly resistant to sun damage, ensuring colors stay vibrant longer, whether in the Arizona sun or humid conditions in Lake Charles.

- Color Stability: Virgin EPDM granules allow for a vast palette of stable, non-fading colors.

- Softness and Durability: This layer adds softness underfoot and is incredibly durable, withstanding heavy foot traffic and weather fluctuations.

Both layers are bound with a specialized polyurethane resin to create a cohesive, resilient surface.

Key Material Components

Understanding the core materials is key to appreciating the quality of EPDM wet pour rubber surfacing:

- EPDM (Ethylene Propylene Diene Monomer): These virgin rubber granules form the colorful top layer, known for excellent UV stability, chemical resistance, and long-term elasticity. Our EPDM granules contain up to 25% polymers with premium UV stabilizers for superior performance. Learn more at our EPDM Rubber Playground page.

- SBR (Styrene-Butadiene Rubber): The workhorse of the base layer, SBR granules are derived from recycled tires, providing a sustainable source of shock absorption to meet fall height requirements.

- Polyurethane Binder: This “glue” cures on-site to bond the rubber granules. There are two main types:

- Aromatic Binder: A cost-effective choice, though it may yellow slightly with UV exposure. This effect typically diminishes over time.

- Aliphatic Binder: A premium, UV-stable option that prevents yellowing and preserves the vibrancy of EPDM colors, especially lighter shades. It also improves durability.

The recycled content of our EPDM wet pour rubber surfacing is a point of pride. The SBR base is 100% post-consumer recycled material. The total recycled content of the entire system ranges from 82% to 96%, turning environmental waste into safe, functional spaces.

The Best Benefits: Safety, Durability, and Sustainability

Choosing the right surface for a play area impacts safety, enjoyment, and long-term value. We believe EPDM wet pour rubber surfacing offers an unparalleled combination of benefits, making it the superior choice for projects from a Charlotte park to a community space in Nashville.

Prioritizing Safety with EPDM Wet Pour Rubber Surfacing

Safety is the top priority for any play area. EPDM wet pour rubber surfacing is engineered to minimize fall-related injuries, offering superior protection.

- Critical Fall Height (CFH) Compliance: The surface thickness is determined by the CFH of the play equipment, ensuring it can absorb impacts from a specific height. Our systems are tested to meet ASTM F1292 standards for fall heights up to 10-13 feet.

- HIC and GMAX Scores: Our systems achieve excellent Head Injury Criterion (HIC) and GMAX scores, the key metrics for measuring impact safety, signifying exceptional performance.

- ADA Compliance: The seamless, smooth surface is fully compliant with the Americans with Disabilities Act (ADA) per ASTM F-1951, ensuring accessibility for everyone.

- Slip Resistance: The textured rubber provides essential slip resistance, even when wet, which is crucial for splash pads in Lake Charles or pool decks in Tucson.

- Seamless Design: The on-site installation creates a continuous surface, eliminating trip hazards like seams or gaps.

As a trusted Playground Safety Surfacing Company, we adhere to guidelines like the Public Playground Safety Handbook – CPSC Publication 325.

Durability and Longevity

EPDM wet pour rubber surfacing is also known for its resilience and long-term value.

- Weather Resistance: The material is flexible and resistant to extreme temperatures, making it ideal for diverse climates from Connecticut winters to Arizona summers.

- UV Stability: High-quality EPDM granules and optional aliphatic binders resist UVA and UVB rays, preventing cracking and color fading.

- Heavy Foot Traffic: Designed for high-use areas, the surface maintains its structural integrity under constant play.

- Expected Lifespan: With basic maintenance, the surface can last 10 to 15 years, far surpassing options like wood chips.

- Warranty Options: We offer substantial warranties, often up to 7-10 years, providing peace of mind and protecting your investment.

Environmental and Sustainability Aspects

Choosing EPDM wet pour rubber surfacing has a significant positive environmental impact.

- Recycled Tire Usage: The base layer is made from SBR rubber granules derived from recycled tires, addressing the environmental challenge of tire disposal.

- Diverting Tires from Landfills: Every square foot of surfacing diverts 1-2 pounds of rubber from landfills. Our projects in Raleigh and Columbia contribute to recycling millions of pounds of rubber.

- Sustainable Construction: By using post-consumer materials, we reduce the demand for virgin resources. Learn more about our Recycled Rubber Playground Flooring.

- High Recycled Content: Our systems achieve a total recycled content between 82% and 96%, making them a deeply responsible and eco-friendly choice.

Design, Applications, and Cost-Effectiveness

Beyond safety and sustainability, EPDM wet pour rubber surfacing offers a world of creative possibilities and practical applications that make it a smart investment.

Endless Design Possibilities

One of the most exciting aspects of EPDM wet pour rubber surfacing is its aesthetic flexibility. Because it’s installed on-site, we can “draw” with rubber, making it a dream material for designers.

- Color Mixing: We offer over 15 EPDM colors that can be blended to create custom schemes, like matching school colors for a playground in Sanford.

- Custom Logos and Graphics: We can seamlessly integrate logos, crests, or any custom graphic directly into the surface.

- Themed Designs: From ocean waves to jungle paths, the surface can be shaped and colored to bring any theme to life.

- 3D Play Elements: We can incorporate 3D half spheres and full spheres for visual interest and sensory play.

- Geometric Patterns: Intricate patterns, stripes, and borders add a sophisticated touch.

- Educational Games: The surface can become an interactive learning tool with embedded games like hopscotch, alphabets, and numbers. See more ideas for Colored Rubber Surfaces for Playgrounds.

Typical Applications for EPDM Wet Pour Rubber Surfacing

While common for playgrounds, its versatility extends to many other spaces:

- Playgrounds: Its primary application, providing a safe, accessible, and vibrant environment.

- Splash Pads: Its porous and slip-resistant nature is ideal for water play areas. See our Rubber Pool Deck Surfacing solutions.

- Sports Courts: EPDM offers excellent impact absorption for basketball courts and multi-sport areas. Explore our Rubber Surfacing for Sports Courts.

- Walking Paths and Jogging Trails: The shock-absorbing surface is a softer alternative to concrete or asphalt.

- Patios and Outdoor Living Spaces: A stylish and comfortable choice for residential patios.

- Fitness Areas: The cushioned surface is perfect for outdoor fitness zones.

- Daycare Centers, Schools, and Care Homes: Provides a safe, anti-slip surface for all ages.

Comparing EPDM Wet Pour Rubber Surfacing to Other Playground Surfaces

When compared to other options, EPDM wet pour consistently emerges as a superior choice in critical areas.

| Feature | EPDM Wet Pour Rubber Surfacing | Wood Chips / Engineered Wood Fiber (EWF) | Sand / Pea Gravel | Rubber Mulch (Loose-Fill) |

|---|---|---|---|---|

| Safety (CFH) | Excellent (up to 13 ft), consistent impact absorption. | Good (up to 12 ft), but requires constant maintenance. | Variable (up to 10 ft), prone to displacement. | Good (up to 12 ft), but displacement is an issue. |

| Maintenance | Low (sweeping, occasional washing/re-sealing). | High (regular raking, topping up, weed control). | High (raking, cleaning, sifting, topping up). | Moderate (raking, topping up). |

| Durability | Excellent (10-15 years), weather/UV resistant. | Moderate (3-5 years), decomposes, can blow away. | Moderate (5-8 years), can blow away, gets dirty. | Good (10+ years), but can fade and displace. |

| Accessibility (ADA) | Excellent (seamless, smooth, firm). | Poor (loose, difficult for wheelchairs, canes). | Poor (loose, difficult for wheelchairs, canes). | Poor (loose, difficult for wheelchairs, canes). |

| Aesthetics | Excellent (unlimited colors, custom designs, seamless). | Natural look, but can look messy. | Natural look, but can look messy and attract animals. | Good (various colors), but can fade and look artificial. |

| Porous/Drainage | Excellent (drains quickly, all-weather use). | Good, but can hold moisture and freeze. | Good, but can hold moisture and freeze. | Excellent, drains quickly. |

| Long-Term Cost | Moderate to High initial, but low long-term due to durability/low maintenance. | Low initial, but high long-term due to constant replenishment/maintenance. | Very Low initial, but high long-term due to replenishment/maintenance. | Moderate initial, but can be high due to displacement/topping up. |

While the initial investment for EPDM wet pour rubber surfacing is higher than for loose-fill options, its low maintenance, long lifespan, and superior safety make it more cost-effective over time. Professional installation is key to ensuring quality and safety. For more details, see our Best Playground Flooring Ultimate Guide and our breakdown of Understanding Rubber Playground Surfacing Costs.

Installation and Long-Term Care

The success of your EPDM wet pour rubber surfacing depends on professional installation and proper care. At Replay Surfacing, our teams have experience creating flawless surfaces in regions from Tucson to Indiana and Connecticut, bringing local expertise to every project, including those for Rubber Surfacing Charlotte Patios Pools Driveways.

The Installation Process from Start to Finish

Installing EPDM wet pour rubber surfacing is a precise, multi-step process:

- Site Preparation: The area is cleared and leveled with a suitable sub-base like compacted crushed stone, asphalt, or concrete. Proper drainage (1-2% gradient) is established.

- Edge Formwork: Secure edging is installed around the perimeter to contain the mixture.

- Priming the Base: A primer is applied to the sub-base to ensure optimal adhesion.

- Mixing the Base Layer: SBR granules are mixed with a polyurethane binder (10-12% by weight).

- Applying the Base Layer: The SBR mixture is poured and spread to the required depth based on the Critical Fall Height, then compacted.

- Mixing and Applying the Top Layer: While the base is tacky, EPDM granules are mixed with binder (18-20% by weight) and spread over the base to a 15-20mm thickness.

- Troweling Technique: Skilled installers use steel trowels to smooth and compact the EPDM layer, creating a seamless finish.

- Edge Finishing: Edges are carefully finished for a clean transition.

- Curing Period: The surface requires 24 hours before light foot traffic and 3-7 days to fully cure, depending on conditions.

While professional installation is recommended for safety-critical surfaces, our guide on Rubber Wetpour DIY offers tips for smaller projects.

Maintenance and Troubleshooting Tips

Regular maintenance will help your surface last 10-15 years.

- Regular Cleaning: Sweep weekly to remove debris. Wash monthly with a low-pressure hose and mild detergent. Address stains promptly using rubber-safe cleaners, avoiding harsh chemicals.

- Minor Repairs: Use DIY repair kits to patch small holes or cracks.

- Re-sealing (Roll Coat): Apply a re-sealing coat every 2-3 years to protect against UV damage and refresh the color.

- Seasonal Upkeep: Clear leaves in the fall to prevent staining. In winter, use rubber-bladed snow removers and pet-friendly ice melt instead of rock salt.

- Troubleshooting: Address loose granules (granulation) with a rebinder product. Patch cracks with repair kits. Treat moss or algae with a rubber-safe killer.

- Professional Inspections: We recommend yearly professional inspections to identify and address potential issues early.

Certifications and Standards: Ensure your surfacing complies with key safety standards:

- ASTM F1292: Standard for impact attenuation and critical fall height ratings.

- ASTM F1951: Standard for ADA accessibility.

- ASTM F2479: Guide for the installation and maintenance of poured-in-place surfacing.

- IPEMA Certification: The International Play Equipment Manufacturers Association (IPEMA) provides third-party certification to ensure products meet ASTM safety standards. Our systems are IPEMA certified for various fall heights. You can verify certifications at https://ipema.org/.

- EN 1177:2018: The European standard for impact attenuating playground surfacing.

Frequently Asked Questions about EPDM Wet Pour Surfacing

Here are answers to some of the most common inquiries we receive about EPDM wet pour rubber surfacing.

What is the Critical Fall Height and why is it important?

The Critical Fall Height (CFH) is a safety rating that represents the maximum height from which a person can fall onto the surface without sustaining a life-threatening head injury, as tested per ASTM F1292.

Why it’s important: The surfacing’s CFH must be equal to or greater than the highest potential fall height of the play equipment. If a slide platform is 8 feet high, the surface must have a CFH rating of at least 8 feet to provide adequate impact absorption and prevent severe injuries.

How long does EPDM wet pour surfacing last?

With proper installation and maintenance, EPDM wet pour rubber surfacing has an expected lifespan of 10 to 15 years.

Factors that influence its longevity include:

- UV Exposure: Intense sun (like in Tucson, AZ) can contribute to degradation over many years if the surface is not maintained with re-sealing.

- Foot Traffic: High-traffic zones, like under swings, experience more wear. We can reinforce these areas for added durability.

- Maintenance Quality: Regular cleaning, prompt repairs, and periodic re-sealing are crucial to extending the surface’s life.

- Professional Installation: A correctly installed surface will always outlast a poorly installed one.

Is EPDM wet pour surfacing environmentally friendly?

Yes. EPDM wet pour rubber surfacing is a leader in sustainable construction.

Here’s why:

- Recycled SBR Rubber: The base layer is composed of SBR granules from recycled tires, diverting millions of pounds of waste from landfills annually.

- Diverting Waste: By using recycled tires, we actively reduce landfill waste and conserve resources on projects from Lake Charles to Raleigh.

- Sustainable Choice: Choosing this surfacing aligns with green building practices, turning an environmental hazard into a safe, long-lasting product. Learn more about Sustainable Construction Materials.

- High Recycled Content: Our complete systems have an impressive recycled content of 82% to 96%, making it one of the most eco-friendly surfacing options available.

Conclusion

EPDM wet pour rubber surfacing represents the pinnacle of modern recreational and safety surfacing. It offers an best combination of benefits that make it the ideal choice for playgrounds, splash pads, sports courts, and various other applications across our communities in Charlotte, Nashville, Tucson, and beyond.

We’ve explored how this innovative, two-layer system, constructed from a shock-absorbing SBR base of recycled tires and a vibrant, UV-stable EPDM top layer, delivers on all fronts:

- Safety: With critical fall height ratings up to 13 feet, ADA compliance, and superior slip resistance, it provides unparalleled protection for users.

- Durability: Its resilience to weather extremes, UV radiation, and heavy traffic ensures a long-lasting, low-maintenance surface that can endure for 10-15 years.

- Aesthetics: The boundless design possibilities, from custom logos to educational games and a vast palette of colors, allow for the creation of truly unique and inspiring spaces.

- Sustainability: By changing millions of pounds of waste tires into safe, functional surfaces, we actively contribute to a greener future.

At Replay Surfacing, we are passionate about changing environmental hazards into sustainable, customizable, and durable surfaces. Our expertise in EPDM wet pour rubber surfacing ensures that every project we undertake not only meets but exceeds expectations for safety, performance, and beauty.

Ready to create a safer, more vibrant space? We invite you to explore our comprehensive Explore our playground surfacing solutions and find how we can bring your vision to life.