Why the Best Playground Ground Cover in Charlotte Matters for Your Child’s Safety

The best playground ground cover in Charlotte is recycled rubber surfacing due to its superior fall protection, ADA compliance, durability, and low maintenance requirements. Here’s what matters most:

Top Ground Cover Options:

- Poured-in-place rubber – Best overall safety and accessibility

- Rubber tiles/mats – Easy installation with excellent protection

- Recycled rubber mulch – Cost-effective with good impact absorption

- Engineered wood fiber – Budget-friendly but requires more maintenance

- Synthetic turf with padding – Natural look with safety features

Over 200,000 children visit emergency rooms each year due to playground injuries, with more than half caused by falls onto hard surfaces. The right ground cover can mean the difference between a minor tumble and a serious head injury.

Your playground surface affects:

- Fall injury prevention

- Wheelchair and mobility device access

- Long-term maintenance costs

- Environmental sustainability

- Overall play experience

Whether you’re managing a school playground, designing a community park, or installing backyard equipment in the Charlotte area, choosing the right surface material impacts safety, accessibility, and your budget for years to come.

I’m Landon Olson, a mechanical engineer with an MBA who has spent years in the safety surfacing industry, helping facilities in Charlotte find the best playground ground cover solutions that protect children while meeting environmental goals. Through my work at Replay Surfacing, I’ve seen how the right surface choice transforms playgrounds into safer, more inclusive spaces.

Easy best playground ground cover Charlotte glossary:

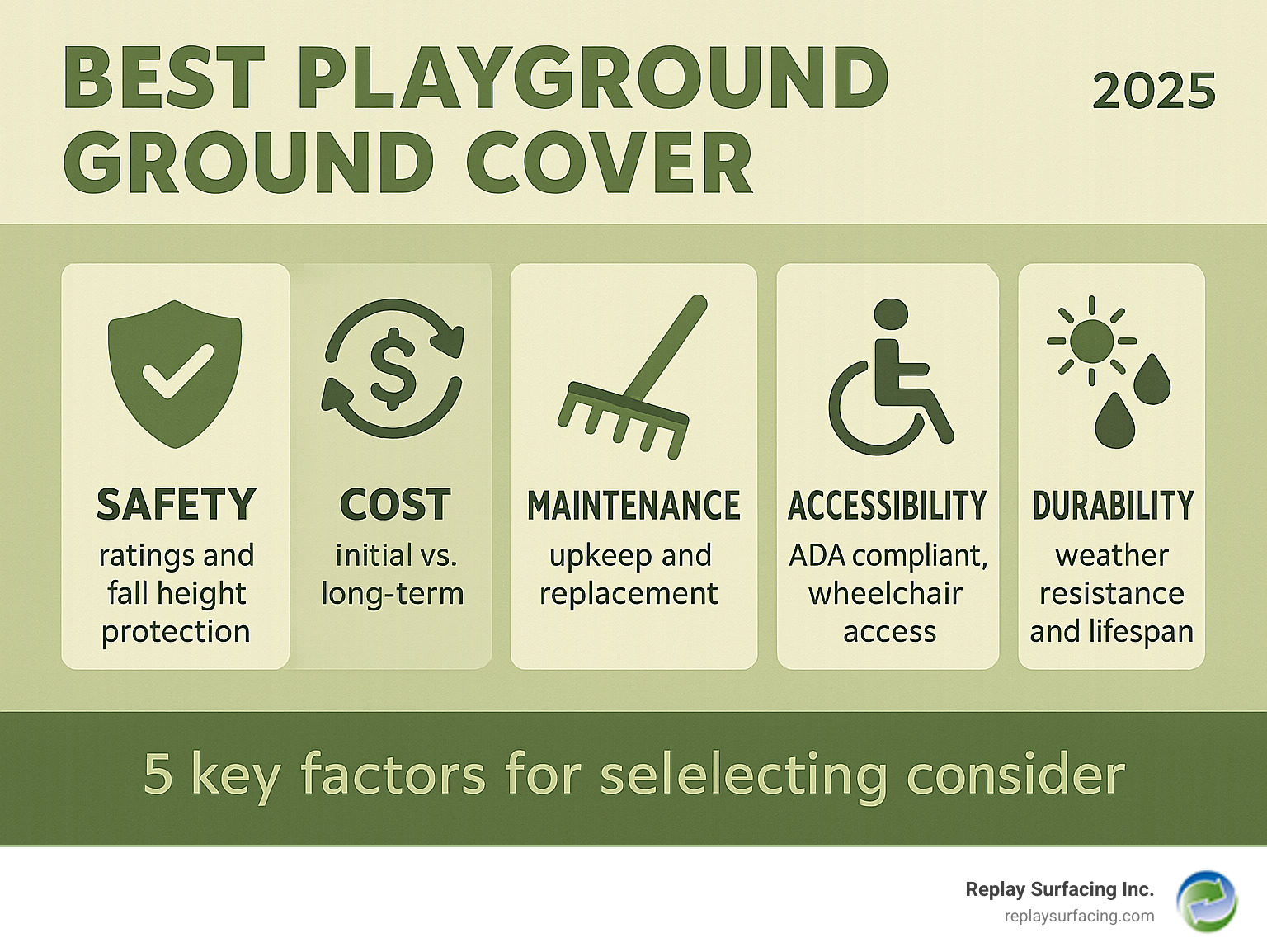

Key Factors in Choosing Playground Surfacing in Charlotte

Choosing the best playground ground cover in Charlotte isn’t just about picking something soft to land on. It’s about creating a safe, welcoming space where every child can play confidently, whether they’re climbing monkey bars or racing across a playground in Charlotte.

Think of it like choosing a car – you wouldn’t just look at the color, right? You’d consider safety ratings, fuel efficiency, and how it handles in your local weather. The same thoughtful approach applies to playground surfaces.

Safety Standards and Fall Height Protection

Here’s a sobering fact: falls cause most playground injuries, and the United States Consumer Product Safety Commission (CPSC) tracks over 200,000 emergency room visits each year from playground accidents. That’s why fall height protection sits at the top of our priority list.

Every piece of playground equipment has a specific fall height rating, and your surface must match or exceed that protection level. A 6-foot slide needs different impact absorption than a 12-foot climbing structure. The National Program for Playground Safety has shown that head injury severity directly correlates with fall height, making this calculation critical for any playground installation.

We always recommend surfaces that meet American Society of Testing and Materials (ASTM) standards and carry CPSC guidelines compliance. These aren’t just bureaucratic boxes to check – they’re proven safety measures that can prevent serious injuries.

Accessibility and ADA Compliance

A truly great playground welcomes every child. That means ensuring wheelchair accessibility and mobility device access from day one. ADA compliance for playgrounds requires firm, stable surfaces beneath all accessible equipment.

Picture a child in a wheelchair trying to steer loose wood chips or sand – it’s nearly impossible and frankly unfair. Unitary surfaces like poured rubber create smooth pathways that allow every child to reach the fun, regardless of their mobility needs.

Long-Term Maintenance and Durability

Let’s talk about the real cost of playground surfaces – and it’s not just the upfront price tag. Some materials seem budget-friendly until you factor in constant maintenance, regular replenishment, and early replacement needs.

Upfront cost vs. lifecycle cost tells the real story. A surface that costs more initially but requires minimal upkeep often proves more economical over 10-15 years. Whether you’re managing a school playground or a community park in the Charlotte area, your maintenance budget and staff time are precious resources.

Durability varies dramatically between materials. Some surfaces withstand decades of active play with minimal care, while others need attention every few months to maintain safety standards.

Aesthetics and Design Flexibility

Playgrounds should spark joy and imagination! The right surface contributes significantly to creating an inviting, vibrant play environment. Bright colors and appealing textures make playgrounds more attractive to children and can even improve the surrounding community’s appeal.

Modern surfacing options offer incredible design flexibility, allowing you to incorporate logos, games, or colorful patterns directly into the surface. Think hopscotch courts, alphabet learning areas, or school mascot designs seamlessly integrated into the safety surface.

Climate Considerations

Your local weather plays a huge role in determining the best playground ground cover in Charlotte. Charlotte’s climate, with its hot, humid summers and occasional winter freezes, presents unique challenges. Heat retention is a major concern during summer months, as some surfaces can become uncomfortably hot. Materials must also withstand freeze-thaw cycles during winter to prevent cracking. Furthermore, with significant rainfall throughout the year, excellent drainage properties are essential to prevent standing water and ensure playgrounds remain usable and safe.

UV degradation affects many materials over time, causing colors to fade and surfaces to break down. We always assess your specific geographic location to recommend surfaces that will perform optimally year-round in your local conditions.

Loose-Fill Ground Covers: Pros and Cons

Loose-fill surfaces are the traditional playground materials many of us remember from childhood. These granular materials spread beneath equipment offer certain advantages but come with significant challenges.

Engineered Wood Fiber (EWF) represents the premium option among loose fills. When properly maintained at 9 inches deep, it can cushion falls from up to 10 feet. It’s made from new wood without chemical treatments, making it relatively safe. However, it requires constant maintenance to maintain proper depth, especially in high-traffic areas where it compacts and displaces.

Sand offers good drainage and sensory play opportunities, but it easily scatters into shoes, clothing, and cars. When wet, sand packs down hard, losing its shock-absorbing properties. It can also harbor bacteria and poses accessibility challenges for mobility devices.

Pea gravel provides excellent drainage and resists insects better than wood options. Its smooth, rounded stones won’t splinter, but like sand, it displaces easily and offers limited fall protection without significant depth.

All loose-fill options share common displacement issues – they scatter outside play areas, requiring frequent replenishment and ongoing costs. Hidden hazards like broken glass or animal waste can easily be concealed within loose materials, creating safety risks.

For more detailed information, check out our comprehensive guide on Loose Fill Playground Surfacing.

Unitary Ground Covers: Pros and Cons

Unitary surfaces represent the modern approach to playground safety – solid, continuous surfaces that deliver consistent performance across the entire play area.

Poured-in-place rubber stands as the gold standard for playground surfacing. It offers exceptional safety with uniform shock absorption, full ADA compliance, and incredible design flexibility. While the initial investment is higher, its durability and minimal maintenance requirements often make it the most cost-effective long-term choice. Our expertise in Poured in Place Rubber: The Ultimate Playground Safety Surface ensures professional installation and optimal performance.

Rubber tiles and mats provide excellent impact protection with easier installation than poured surfaces. They’re available in various colors and thicknesses, making them suitable for different fall heights and design preferences. Our Rubber Playground Mats and Colored Rubber Surfaces for Playgrounds offer versatile solutions for various playground needs.

Synthetic turf with engineered padding delivers a natural grass appearance without the maintenance headaches of live grass. When properly installed over shock-absorbing pads, it provides excellent fall protection while maintaining an attractive, familiar look.

Recycled rubber mulch (when bound) creates an eco-friendly unitary surface that won’t displace like loose materials. Made from 100% recycled tires, it transforms environmental hazards into safe, durable playground surfaces – perfectly aligning with sustainable construction practices.

These unitary options excel in superior accessibility, providing smooth, stable surfaces for wheelchairs and mobility devices. They offer low maintenance requirements compared to loose fills and deliver design flexibility that allows creative, colorful play environments.

What is the Best Playground Ground Cover in Charlotte for Safety and Accessibility?

After evaluating all the factors we’ve discussed, one truth becomes crystal clear: unitary surfaces consistently outperform loose-fill options when it comes to creating truly safe and accessible playgrounds. This isn’t just our opinion—it’s backed by years of real-world performance data and safety testing.

The evidence is compelling when we look at how these surfaces perform across the most critical areas. Fall height protection varies dramatically between surface types, with loose-fill materials like sand, pea gravel, and engineered wood fiber requiring significant depth—often 9 to 12 inches—to provide adequate cushioning. Even then, these materials compact over time and displace with use, creating dangerous hard spots and thin areas where children are most vulnerable to injury.

Unitary surfaces like poured-in-place rubber and rubber tiles maintain consistent shock absorption across their entire area, meeting or exceeding critical fall height requirements without the constant maintenance headaches. When a child falls on our recycled rubber surfaces, they experience the same level of protection whether it’s day one or year five after installation.

The accessibility difference is night and day. Loose-fill surfaces simply cannot meet ADA compliance standards reliably. Sand shifts underfoot, wood chips create unstable walking surfaces, and pea gravel makes wheelchair navigation nearly impossible. Children using mobility devices, along with parents pushing strollers, struggle with these uneven, shifting surfaces.

Our unitary rubber surfaces create seamless, stable pathways that allow every child to access play equipment safely and independently. Whether it’s interlocking rubber tiles or poured-in-place installations, these surfaces provide the firm, stable foundation that ADA compliance requires—and that inclusive play demands.

From a maintenance perspective, the long-term costs tell the real story. While loose-fill materials might seem budget-friendly upfront, they require constant raking, regular replenishment, and frequent deep cleaning to remove hidden hazards. School districts and park departments often find themselves spending more on maintenance in just a few years than they would have invested in a quality unitary surface from the start.

Durability is where recycled rubber truly shines. Our surfaces withstand extreme weather, heavy use, and the test of time without losing their protective properties. They resist mold, mildew, and pest infiltration—problems that plague organic loose-fill materials like wood fiber.

For communities in Charlotte seeking the best playground ground cover solution, the choice becomes clear when safety and accessibility are priorities. Recycled rubber surfacing offers superior fall protection, full ADA compliance, minimal maintenance requirements, and exceptional durability—all while supporting environmental sustainability by giving new life to discarded tires.

Learn more about our comprehensive Shock Absorbing Playground Surfaces and find how we’re helping communities create safer, more inclusive play spaces.

Critical Fall Height and Safety Certifications

Understanding critical fall height is essential for any playground decision-maker. This measurement tells you the maximum height from which a child can fall onto a surface while staying within acceptable injury risk levels. It’s not just a number—it’s a critical safety standard that can mean the difference between a minor bump and a life-changing head injury.

The American Society of Testing and Materials (ASTM) provides the gold standard for playground safety testing through their F1292 standard. This rigorous testing measures impact attenuation using sophisticated equipment that simulates a child’s head hitting the surface. The results determine each surface’s Head Injury Criterion (HIC) rating—a crucial measurement that playground designers use to match surfaces with equipment heights.

CPSC guidelines work hand-in-hand with ASTM standards to establish comprehensive safety requirements. The Consumer Product Safety Commission’s recommendations aren’t just suggestions—they’re based on extensive analysis of playground injuries and provide the framework that helps prevent serious accidents.

IPEMA certification takes these standards one step further by providing independent verification that surfaces meet all required safety benchmarks. When you see IPEMA certification on a playground surface, you know it has undergone rigorous third-party testing and continues to meet strict quality standards.

Here’s what many people don’t realize: professional installation is absolutely critical for achieving certified performance levels. Even the highest-quality materials can fail to provide adequate protection if they’re not installed correctly. Our certified installers understand the precise techniques required to ensure your surface performs exactly as tested and certified.

At Replay Surfacing, we specialize in surfaces that not only meet but exceed these critical safety standards. Our Playground Safety Surfacing Company expertise ensures that every installation delivers the protection your community deserves, backed by proper certifications and professional installation practices.

The National Program for Playground Safety emphasizes that fall height considerations must be the foundation of every playground design decision. When you choose certified, professionally installed unitary surfaces, you’re making an investment in long-term safety that protects children and provides peace of mind for families and facility managers alike.

Finding the best playground ground cover in Charlotte for ADA Compliance

Creating truly inclusive playgrounds means understanding that accessibility isn’t an afterthought—it’s a fundamental design principle that shapes every decision we make. When children using wheelchairs, walkers, or other mobility devices arrive at a playground, the surface beneath their wheels determines whether they can participate fully or watch from the sidelines.

ADA compliance requires surfaces to be firm and stable, which sounds simple but has profound implications for surface selection. The Americans with Disabilities Act doesn’t just suggest accessibility—it requires it, and playground surfaces play a crucial role in meeting these legal and ethical obligations.

Loose-fill materials create immediate barriers for children with mobility challenges. Imagine trying to steer a wheelchair through sand or wood chips—it’s exhausting, frustrating, and often impossible. These surfaces shift and compress under the weight of mobility devices, creating an unstable foundation that makes independent play nearly impossible.

Unitary surfaces transform accessibility from a challenge into a seamless experience. Our poured-in-place rubber and interlocking tile systems create smooth, consistent pathways that allow children using mobility devices to move freely throughout the play area. The difference is remarkable—children who might have been limited to watching from accessible seating can now reach every piece of equipment independently.

The benefits extend far beyond wheelchair accessibility. Parents pushing strollers, children with balance challenges, and kids using crutches or walkers all benefit from stable, non-slip surfaces. Even children without mobility devices play more confidently on surfaces that provide consistent footing and cushioning.

Our Poured in Place Rubber: The Ultimate Playground Safety Surface represents the gold standard for accessible playground design. This seamless surface eliminates gaps, joints, and uneven areas that can catch wheels or create tripping hazards. The result is a playground where accessibility feels natural and unforced.

Creating inclusive play spaces means thinking beyond minimum compliance to consider the full experience of every child who visits your playground. When we install accessible surfaces, we’re not just meeting legal requirements—we’re opening up worlds of play and social interaction for children who might otherwise be excluded.

The impact on communities is profound when playgrounds become truly accessible. Parents report that their children with mobility challenges gain confidence, make new friends, and develop physical skills they couldn’t practice on traditional playground surfaces. This is why we’re passionate about helping communities in Charlotte choose the best playground ground cover solutions that welcome every child.