Why Eco Safety Rubber Playground Surfacing in Connecticut Matters for Today’s Play Spaces

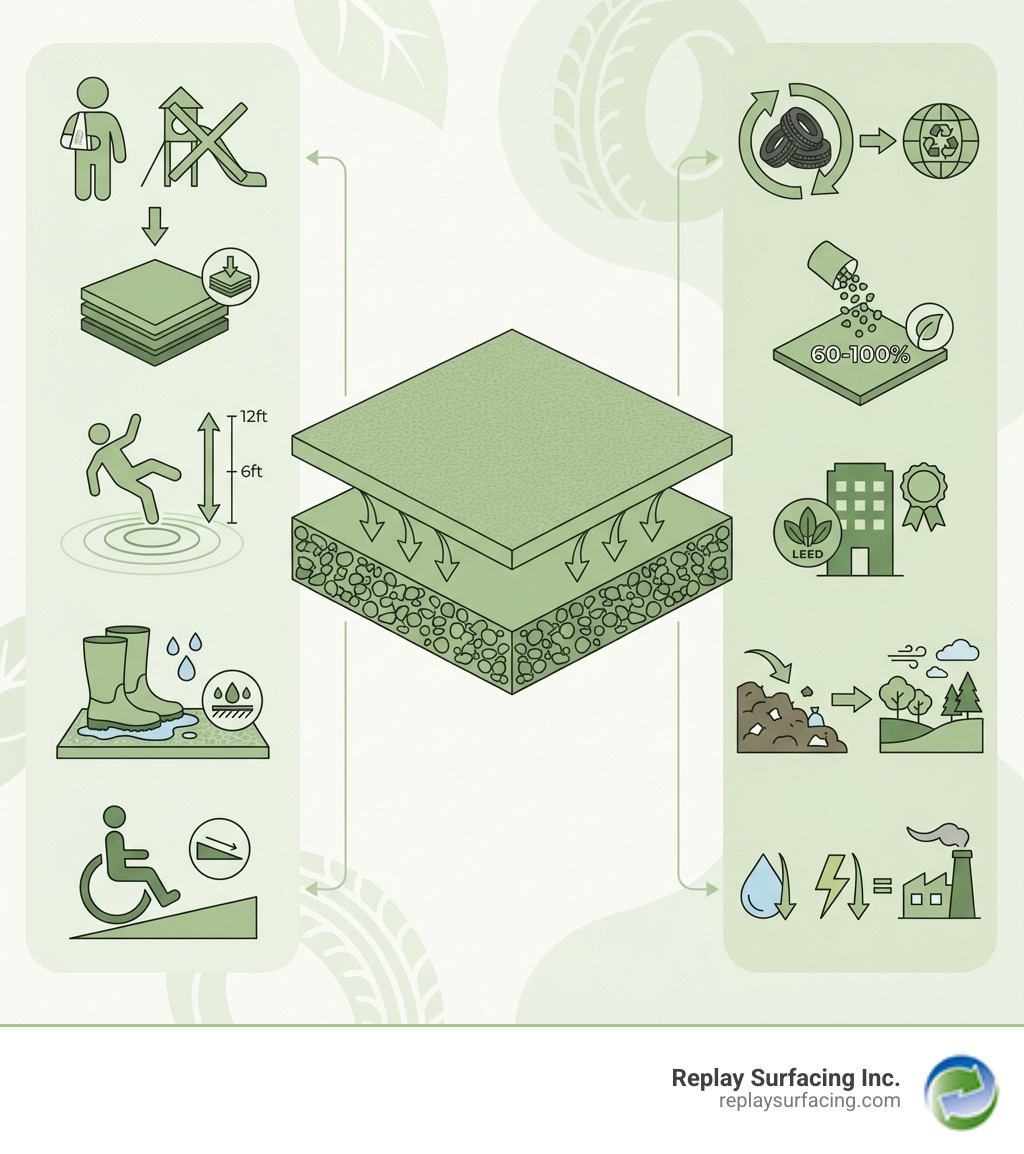

Eco safety rubber playground surfacing in Connecticut is a protective, cushioned surface made from recycled rubber (often from used tires) designed to reduce playground injuries while supporting environmental sustainability. Here’s what you need to know:

- Safety: Tested to cushion falls from heights up to 6-12 feet, meeting ASTM F1292 standards

- Eco-Friendly: Made from recycled tires, diverting waste from landfills and conserving resources

- Types: Available as poured-in-place (seamless) or interlocking tiles (DIY-friendly)

- Durability: Lasts 12-15 years with proper maintenance

- Accessibility: Meets ADA compliance for wheelchair users

- Maintenance: Simple cleaning with hoses, brooms, or leaf blowers

Every year, more than 200,000 children ages 14 and younger are treated in emergency rooms for playground-related injuries. The surfacing under and around playground equipment is one of the most important factors in reducing the likelihood of life-threatening head injuries. But safety isn’t the only concern—with about 290 million scrap tires generated in the U.S. annually, eco-conscious facility managers are seeking solutions that protect both children and the planet.

That’s where eco safety rubber playground surfacing in Connecticut comes in. This innovative material transforms environmental waste into a dual-benefit solution: exceptional fall protection combined with meaningful waste reduction. Whether you’re managing a school playground in Connecticut, a daycare in Indiana, or a community park in Tennessee, choosing the right surfacing isn’t just about compliance—it’s about creating spaces where children can play safely while you contribute to a healthier environment.

I’m Landon Olson, operator of Replay Surfacing, where we’ve spent years recycling millions of pounds of scrap tires into high-quality eco safety rubber playground surfacing solutions. With my background in mechanical engineering and sustainability, I’ve seen how the right surfacing choice can transform both safety outcomes and environmental impact for communities across our service areas.

Simple guide to eco safety rubber playground surfacing terms:

The Unbeatable Safety of Eco Safety Rubber Playground Surfacing in Connecticut

When we talk about playgrounds, safety is always our paramount concern. Children, with their boundless energy and adventurous spirits, are bound to take a tumble now and then. While we can’t prevent every fall, we can certainly minimize the risk of serious injury. This is precisely where eco safety rubber playground surfacing in Connecticut shines, offering a level of protection that traditional surfaces simply cannot match.

Imagine a child falling from a swing onto unforgiving concrete or asphalt. The consequences can be devastating, often leading to life-threatening head injuries. This is why the surfacing beneath and around playground equipment is considered one of the most critical factors in reducing such severe outcomes. Our rubber playground surfacing acts as a guardian, absorbing the impact and cushioning falls, making it the best choice for playgrounds across Connecticut, Indiana, Tennessee, and all our service areas.

Our commitment to safety is rooted in the understanding that rubber’s inherent elasticity and low compression set provide exceptional buoyancy and shock absorption. This means that when a child falls, the rubber surface compresses and then springs back, dissipating the energy of the impact and significantly reducing the force transmitted to the child’s body. This is a stark contrast to hard surfaces like concrete or asphalt, which offer no give, transferring the full force of the fall directly to the child. Even seemingly softer options like sand or wood chips, while better than concrete, require constant maintenance to maintain their critical depth and can compact over time, losing their protective qualities.

Superior Cushioning and Fall Protection

The effectiveness of our eco safety rubber playground surfacing in Connecticut isn’t just a claim; it’s backed by rigorous testing. Our tiles and poured-in-place systems are engineered to meet stringent safety standards, particularly the ASTM F1292-09 Standards. This certification means our surfacing is rated for specific fall heights, often up to 6 feet, and even higher for some of our thicker systems. For instance, some of our 2.5-inch tiles are rated for a 6ft fall height, while 3-inch tiles can be approved for 7-foot fall heights. This certification provides peace of mind, knowing that our surfaces are designed to protect against severe head injuries.

The secret to this superior cushioning often lies in innovative design features. Many of our rubber playground mats feature a waffled bottom design. This clever engineering traps air, which further improves the bounce-back ability and comfort of the surface. When compressed during a fall, these waffle patterns maximize impact attenuation, ensuring that the critical fall height requirements are met, even exceeded, for the equipment installed above. We understand that children in busy parks in Charlotte, NC, or schoolyards in Tucson, AZ, deserve the best possible protection.

The U.S. Consumer Product Safety Commission (CPSC) emphasizes that protective surfacing is non-negotiable. Surfaces like grass, dirt, concrete, or asphalt are simply not considered protective. Our rubber surfacing provides a consistent, reliable cushioning layer that absorbs impact energy, significantly reducing the severity of injuries from falls. For more insights into choosing safe materials, we encourage you to consult reports such as this one on choosing safer materials for playgrounds.

All-Weather Traction and Accessibility

Beyond cushioning falls, our eco safety rubber playground surfacing in Connecticut offers another crucial safety benefit: excellent traction. Recycled rubber, by its very nature, often has a slightly rough texture, which naturally improves gripping ability. This is especially vital in outdoor environments where play continues regardless of the weather. Our surfaces are designed to be non-slip, providing a secure footing for children running, jumping, and playing, even in wet conditions.

Our porous surfacing systems allow water to drain through, preventing puddles and maintaining a consistent, slip-resistant surface year-round. This means less downtime for your playground after rain and a safer play environment for children. Whether it’s a humid summer day in Lake Charles, Louisiana, or a damp autumn afternoon in Connecticut, our surfaces perform reliably.

Accessibility is another cornerstone of our design philosophy. We believe every child deserves the opportunity to play. Many traditional playground surfaces, such as loose-fill sand, wood mulch, or recycled rubber mulch, can be challenging or impossible for children using wheelchairs or other mobility aids. Our poured-in-place rubber surfacing and rubber tiles are engineered to be wheelchair accessible, meeting ADA regulations. This means smooth, firm, and level pathways that provide adequate traction, enabling children of all abilities to steer and enjoy the playground freely. We ensure our installations in Indiana, Tennessee, and all our communities are compliant with these vital standards. You can learn more about these requirements in the ADA guidelines for play surfaces.

The “Eco” in Eco Safety Rubber Playground Surfacing in Connecticut

At Replay Surfacing, “eco” isn’t just a buzzword; it’s a fundamental principle embedded in our product. We are immensely proud to transform what was once an environmental burden into a vibrant, safe, and sustainable solution for play spaces. The sheer volume of waste tires generated annually in the U.S.—estimated at 290 million scrap tires—presents a colossal environmental challenge. Our work directly addresses this, turning these discarded materials into valuable resources.

Using recycled rubber for playground surfacing significantly impacts waste reduction and resource conservation. Instead of ending up in landfills, where they can pose fire hazards, harbor pests, and leach chemicals into the soil and water, these tires are given a new, purposeful life. This circular economy approach not only diverts waste but also conserves virgin resources that would otherwise be used to create new rubber products.

The environmental benefits extend beyond waste diversion. The manufacturing of recycled rubber flooring requires substantially less energy and water compared to producing new rubber products. This reduction in resource consumption contributes to a lower carbon footprint and a more sustainable manufacturing process overall. From our facilities serving Charlotte, NC, to Tucson, AZ, we are committed to these eco-friendly practices.

From Landfill to Playground: The Recycling Journey

The change of a scrap tire into a safe playground surface is a fascinating journey. It begins with the collection of used tires, often from local communities, preventing them from accumulating in landfills or illegal dumps. Once collected, these tires undergo a meticulous recycling process.

First, the tires are shredded, either mechanically or cryogenically, into smaller pieces. This initial shredding is crucial for breaking down the tough tire structure. Next, advanced sorting processes are employed to remove unwanted materials like steel belts and textile fibers, ensuring that only pure rubber remains. This is often achieved using powerful magnets and screens. Finally, the rubber is cleaned and processed into granules or “crumb rubber” of various sizes, ready to be bound together to form our high-quality playground surfacing.

This entire process is a testament to our dedication to sustainability. By utilizing post-consumer recycled content, often making up 60% or more of our products, we contribute directly to reducing the landfill burden and creating a healthier planet for the children who will play on our surfaces. For a captivating look at this process, we recommend watching this video on insight into turning tires into playgrounds. It truly showcases how waste can be transformed into incredible fun.

Building Green: Sustainability and Certifications

Our commitment to environmental responsibility is further demonstrated by our adherence to green building standards. Many of our recycled rubber products are designed to meet criteria set by respected environmental organizations, such as the U.S. Green Building Council (USGBC) and their Leadership in Energy and Environmental Design (LEED) certification program.

Choosing our LEED-compliant eco safety rubber playground surfacing in Connecticut can contribute to your project’s overall LEED certification, offering multiple credits. These credits include:

- Recycled Content: By incorporating a significant percentage of post-consumer recycled tires, our products directly contribute to this credit.

- Regional Materials: We strive to source recycled tires and manufacture our products within a 500-mile radius where possible, especially for our projects in Charlotte, Raleigh, and Columbia, supporting local economies and reducing transportation emissions.

- Stormwater Management: Our permeable surfacing systems allow rainwater to penetrate rather than run off, reducing the burden on stormwater infrastructure and helping to manage water resources sustainably.

- Low-Emitting Materials: We ensure our products meet strict indoor air quality requirements, contributing to healthier environments.

These certifications and contributions highlight our dedication to not just safety, but also to creating truly sustainable play environments. By choosing our surfacing, you’re making an environmentally conscious decision that gives used rubber a new life and supports a greener future for communities across Connecticut, Indiana, and Tennessee. You can explore the US Green Building Council standards to understand the full scope of these important criteria.

A Guide to Rubber Surfacing Types and Standards in Connecticut

When it comes to selecting the perfect eco safety rubber playground surfacing in Connecticut for your project, you’ll find a range of options, each with its unique advantages. We categorize these primarily into “unitary surfaces,” meaning they form a continuous, stable surface, unlike loose-fill options like sand or wood chips. Understanding the different types, along with their pros and cons, is key to making an informed decision.

Poured-in-Place (PIP) Rubber Surfacing

Poured-in-Place (PIP) rubber surfacing is a highly popular choice, especially for larger, more complex playground designs. It’s a two-layer system applied directly on-site, offering a seamless, custom finish.

Pros:

- Seamless Aesthetic: PIP creates a continuous, smooth surface without seams or gaps, which is not only visually appealing but also prevents tripping hazards and makes it extremely accessible for wheelchairs and other mobility devices.

- Customization: This is where PIP truly shines! We can incorporate intricate designs, logos, and a vibrant array of colors, blending them to create unique patterns and themes. Imagine a playground in Nashville, TN, featuring a musical note design, or a school in Raleigh, NC, with its mascot integrated into the surface.

- Excellent Accessibility: Its seamless nature provides the most consistent accessibility for individuals using mobility devices, easily accommodating slopes, mounds, and contours.

- High Durability: PIP is designed to withstand heavy use and various weather conditions, offering long-lasting performance.

- Superior Cushioning: The two-layer system typically consists of a shock-absorbing base layer made from recycled rubber crumb and a colorful wear layer, often made from EPDM (Ethylene Propylene Diene Monomer) rubber, mixed with a polyurethane binder. The thickness of the base layer is customized to meet specific critical fall height requirements, often protecting up to 12 feet.

Cons:

- Professional Installation: PIP requires specialized equipment and trained installation crews, making it less suitable for DIY projects. However, our experienced teams across Connecticut, Indiana, and Tennessee ensure a flawless installation.

- Cost: Generally, PIP has a higher initial installation cost compared to tiles or loose-fill options, though its longevity and low maintenance can offer long-term value.

- Weather Dependent Installation: Installation requires specific temperature and humidity conditions, ideally between 45 to 105 degrees Fahrenheit.

Interlocking Rubber Playground Tiles

Interlocking rubber playground tiles offer a versatile and often more budget-friendly alternative to PIP, particularly for smaller projects or those where future reconfiguration might be desired.

Pros:

- DIY-Friendly Installation: Many of our interlocking tiles are designed for easy installation, making them a great option for community volunteers or school staff. They typically feature plastic connector pins that fit into holes on the sides, holding the mats firmly together. This ease of installation is a big draw for projects in places like Columbia, SC, or Sanford, NC.

- Easy Repairs: If a tile gets damaged, it can be individually replaced, simplifying maintenance and potentially reducing costs.

- Consistent Thickness: Tiles are manufactured in a controlled environment, ensuring uniform consistency and precise critical fall height ratings. Our “Eco-Safety 2.5-inch” tiles, for example, are rated for a 6ft fall height, and our 3-inch tiles can be rated for 7ft.

- Portability: Tiles can be disassembled and moved if needed, offering flexibility for temporary installations or playground redesigns.

- Comfort and Cushioning: Many tiles feature a waffled bottom design, similar to PIP’s base layer, which traps air to maximize bounce-back ability and comfort.

- Variety: Available in various thicknesses, colors (such as Coal, Green, Blue, and Terra-Cotta), and even pack sizes, allowing for design flexibility. A popular choice for Tennessee daycares and schools.

Cons:

- Seams: Unlike PIP, tiles have visible seams, which can accumulate debris over time.

- Less Customization: While colors and patterns can be created, the design flexibility is not as extensive as with PIP.

- Potential for Shifting: If not properly installed or contained, tiles can sometimes shift, especially in high-traffic areas, though connector pins and optional adhesive minimize this.

Key Safety and Quality Standards to Look For

Regardless of the type of eco safety rubber playground surfacing in Connecticut you choose, ensuring it meets rigorous safety and quality standards is paramount. We at Replay Surfacing are committed to providing products that not only look great but also offer the highest level of protection.

Here are the key standards and certifications you should always look for:

- ASTM F1292: This is the most crucial standard for playground surfacing. It establishes minimum impact attenuation requirements for playground surfaces to reduce the risk of severe head injury from falls. Our products are rigorously tested and certified to meet or exceed these standards, with specific fall height ratings (e.g., 6ft, 7ft, 12ft) corresponding to the thickness and composition of the material.

- ASTM F1951: While primarily associated with Engineered Wood Fiber (EWF), this standard addresses accessibility for individuals using wheelchairs on playground surfaces. For unitary rubber surfaces, the design and installation must ensure compliance with ADA specifications for wheelchair accessibility.

- ADA Compliance: The Americans with Disabilities Act (ADA) mandates that playgrounds be accessible to children with disabilities. This means surfacing must be firm, stable, and slip-resistant, allowing easy movement for wheelchairs and other mobility aids. Both our poured-in-place systems and properly installed rubber tiles meet these critical requirements.

- CPSC Guidelines: The U.S. Consumer Product Safety Commission (CPSC) provides comprehensive public playground safety handbooks. These guidelines offer recommendations on everything from equipment design to surfacing depth and maintenance. We always adhere to CPSC recommendations in our installations across Charlotte, Raleigh, and other locations.

- IPEMA Certification: The International Play Equipment Manufacturers Association (IPEMA) provides third-party certification services for playground equipment and surfacing materials. An IPEMA seal indicates that a product has been tested to relevant ASTM standards. While not directly mentioned for all rubber products in the research, it’s a valuable certification to confirm compliance.

By ensuring your eco safety rubber playground surfacing in Connecticut from Replay Surfacing Inc. is certified to these standards, you’re investing in a play environment that prioritizes the well-being of every child.

Installation, Maintenance, and Lifespan of Connecticut Eco Safety Rubber Playground Surfacing

Investing in eco safety rubber playground surfacing in Connecticut is a significant decision for any community, school, or park. Understanding the installation process, expected lifespan, and maintenance requirements will help you plan effectively and ensure the long-term value of your playground in Connecticut, Indiana, Tennessee, or any of our service areas.

The Installation Process for Your Eco Safety Rubber Playground Surfacing in Connecticut

The installation of rubber playground surfacing can vary depending on whether you choose poured-in-place (PIP) or interlocking tiles. Both methods require careful preparation to ensure optimal performance and durability.

For Poured-in-Place (PIP) systems, the process is typically handled by our professional crews:

- Site Preparation: The area is cleared, leveled, and compacted. Proper drainage is crucial, often involving a base of compacted stone, gravel, or concrete. This ensures a stable foundation and prevents water accumulation under the surface.

- Base Layer Application: Our trained installation teams apply the shock-absorbing base layer, typically made from recycled rubber crumb mixed with a polyurethane binder. The thickness of this layer is precisely determined by the critical fall height requirements of the playground equipment.

- Wear Layer Application: Once the base layer cures, the colorful wear layer (often EPDM granules mixed with a binder) is applied. This is where custom designs and colors come to life.

- Curing: The entire surface then needs adequate time to cure, typically several days, before it can be used.

- Environmental Considerations: For PIP, temperature and humidity play a vital role. Installation is ideally performed when temperatures are between 45 to 105 degrees Fahrenheit to ensure proper curing and adherence. Our professional crews are adept at managing these conditions to ensure a flawless installation, whether in the Arizona heat of Tucson or the humidity of Lake Charles, Louisiana.

For Interlocking Rubber Tiles, the installation can be more DIY-friendly:

- Sub-base Preparation: Similar to PIP, a stable, level sub-base of compacted stone, concrete, or even firm, well-drained dirt or grass is essential.

- Tile Laying: The tiles are laid out according to the desired pattern. Many tiles come with pre-drilled holes for plastic connector pins (often 3.5 inches long) that securely interlock them. This makes for a quick and easy assembly, perfect for a community project in Beaverton, OR.

- Permanent vs. Temporary: For a more permanent installation, especially in high-traffic areas, a polyurethane-based adhesive (such as BASF CX-941) can be used to glue the tiles to a concrete or wood subfloor. For temporary setups, the interlocking pins alone suffice, allowing for easy removal and relocation.

While interlocking tiles can be a great DIY project, our professional crews at Replay Surfacing Inc. bring years of experience and expertise to any installation. This ensures that the surface is compliant with all safety standards, correctly installed for maximum durability, and perfectly custom to your playground’s unique needs.

Long-Term Care and Durability

One of the many benefits of eco safety rubber playground surfacing in Connecticut is its impressive lifespan and relatively low maintenance requirements. With proper care, recycled rubber flooring can last as long as 12-15 years. While some poured-in-place systems might have a life span of 5-8 years before needing a topcoat or significant repair, consistent maintenance can extend this considerably.

Routine cleaning is remarkably simple:

- Basic Cleanup: For everyday debris like leaves, dirt, or light trash, a broom, leaf blower, or vacuum cleaner works perfectly.

- Washing: For a deeper clean, a water hose can be used. For tougher grime or sanitization, a mild detergent and a wet mop are effective. Always avoid harsh chemicals or pressure washing unless explicitly approved by the manufacturer, as these can damage the surface.

- UV Resistance: Our surfaces are designed to be highly durable outdoors, inheriting the innate outdoor resilience of car tires. Many of our products contain EPDM, a UV-stable elastomer, which offers excellent resistance to UV rays and ozone, crucial for playgrounds exposed to intense sun in places like Tucson, AZ.

Regular inspection is also key. Periodically check for any signs of wear, minor tears, or lifting, particularly in high-traffic areas under swings or at slide exits. Small issues can often be addressed with repair kits, which typically include SBR (Styrene Butadiene Rubber), colored EPDM granules, and a binder. Promptly addressing these minor repairs prevents them from escalating into larger, more costly problems.

By following these simple care guidelines, you can maximize your investment, ensuring that your eco safety rubber playground surfacing in Connecticut remains safe, vibrant, and durable for many years, providing a fantastic play environment for children in Connecticut, Indiana, and Tennessee.

Conclusion: Investing in a Safer, Greener Future for Play in Connecticut

Choosing the right playground surfacing is about more than just aesthetics; it’s a profound commitment to the well-being of our children and the health of our planet. Eco safety rubber playground surfacing in Connecticut offers a compelling solution that seamlessly blends unparalleled safety with robust environmental responsibility.

We’ve explored how our rubber surfaces provide superior cushioning and impact absorption, significantly reducing the risk of life-threatening injuries from falls, a critical concern for the 200,000 children treated in emergency rooms each year. We’ve seen how its all-weather traction and ADA compliance ensure that every child, regardless of ability, can play safely and freely.

Beyond safety, the “eco” aspect of our surfacing is a testament to innovation. By changing millions of discarded scrap tires—a major environmental challenge—into durable, beautiful play spaces, we contribute to waste reduction, resource conservation, and a cleaner environment. Our LEED-compliant products reflect our dedication to building green and fostering a circular economy.

Whether you opt for the seamless, customizable beauty of our Poured-in-Place (PIP) systems or the DIY-friendly, easily repairable nature of our interlocking rubber tiles, you’re choosing a product engineered to meet the highest safety standards, including ASTM F1292. With a lifespan of up to 12-15 years and straightforward maintenance, our eco safety rubber playground surfacing in Connecticut offers exceptional long-term value.

At Replay Surfacing Inc., we are passionate about creating exceptional play spaces that inspire joy, encourage activity, and protect our most precious resource: our children. By choosing our solutions, you’re not just installing a playground surface; you’re investing in a safer, greener future for communities across Connecticut, Indiana, Tennessee, and all our service areas.

Ready to transform your playground into a safe, sustainable, and vibrant space? Explore our playground surfacing solutions today and let us help you create a play environment where children can thrive.