Rubber Surfacing Cost in Charlotte, NC: What You Need to Budget

Rubber surfacing cost in Charlotte, NC typically ranges from $8 to $18 per square foot installed for most playground and recreational projects. Here’s what you can expect:

| Surface Type | Cost Per Sq. Ft. | Best For |

|---|---|---|

| Poured-in-Place (PIP) Rubber | $9 – $18 | Playgrounds, splash pads, custom designs |

| Rubber Playground Tiles | $10 – $15 (or $20-$45 per tile) | Gyms, sport courts, DIY installations |

| Rolled Rubber Mats | $1 – $5 | Temporary surfaces, garages |

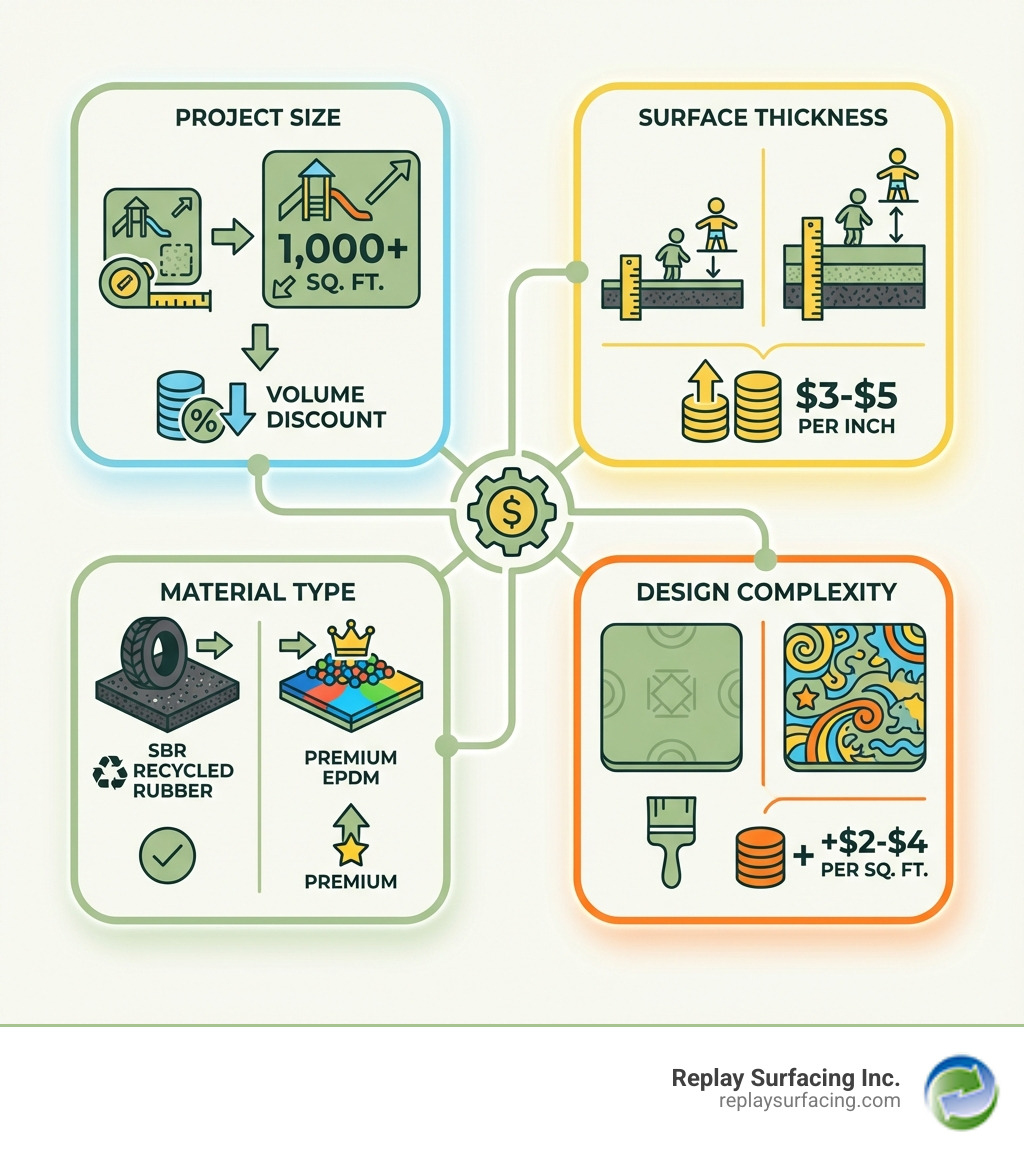

Key Cost Factors:

- Project size (larger areas get volume discounts, dropping to $7-$12/sq. ft.)

- Thickness (1/2″ standard, up to 2-3″ for high fall heights)

- Material type (EPDM vs. SBR rubber)

- Site preparation ($3-$6/sq. ft. for sub-base)

- Custom colors or designs (+$2-$4/sq. ft.)

If you’re managing a facility in Charlotte, Raleigh, Tucson, or surrounding areas, understanding these cost drivers helps you make smart decisions that balance safety, durability, and budget.

Rubber surfacing isn’t just about upfront price. It’s about long-term value. Unlike wood chips or mulch that need annual replacement, quality rubber surfaces last 10-15+ years with minimal maintenance. They meet critical safety standards, provide ADA-compliant accessibility, and transform recycled tires into sustainable, shock-absorbent surfaces that protect children and adults alike.

The challenge? Navigating the variables that affect your final bill. Fall height requirements, color choices, existing surface conditions, and even your geographic location all play a role. Without clear information, it’s easy to underestimate costs or miss opportunities to optimize your investment.

I’m Landon Olson, and as the operator of Replay Surfacing, I’ve helped facility managers across multiple regions understand rubber surfacing cost while changing millions of pounds of scrap tires into safe, sustainable playground and sports surfaces. My background in mechanical engineering and sustainability gives me a unique perspective on balancing safety, environmental impact, and cost-effectiveness. Let’s break down exactly what you’re paying for—and why it matters.

Terms related to rubber surfacing cost in Charlotte, NC:

Poured-in-Place vs. Rubber Tiles: A Cost Comparison

When considering rubber surfacing cost, one of the first decisions you’ll face is between poured-in-place (PIP) rubber and rubber tiles. Both offer exceptional safety and durability, but their applications, aesthetics, and price points differ. At Replay Surfacing, we proudly offer both options across our service areas, including Charlotte NC, Columbia SC, Raleigh NC, Sanford NC, Tucson AZ, Connecticut, Indiana, Nashville TN, Beaverton OR, and Lake Charles Louisiana.

Poured-in-Place (PIP) Rubber Surfacing Cost

Poured-in-place rubber, also known as wet pour rubber or bonded rubber, creates a seamless, resilient surface by mixing rubber granules with a binder on-site and then hand-troweling it into place. This method allows for incredible design flexibility, enabling us to create custom patterns, logos, and intricate color combinations that bring your vision to life.

The average rubber surfacing cost for PIP can range from $9 to $18 per square foot installed for projects 1000 sq. ft. or larger. For the PIP top layer alone, depending on its thickness, you might see costs between $10 and $15 per square foot. This method is ideal for playgrounds, splash pads, and other recreational areas where a smooth, continuous surface is desired. Its seamless nature means no tripping hazards from shifting tiles, making it an excellent choice for high-traffic zones in schools and daycares across our service regions.

We believe in making informed decisions about your surfacing. Learn more about the factors influencing PIP costs in our detailed guide: Understanding Rubber Playground Surfacing Costs.

Rubber Playground Tile Cost

Rubber playground tiles offer a different approach to rubber surfacing. These are pre-manufactured, interlocking tiles, typically made from recycled rubber. They are laid over a prepared sub-base, creating a safe and cushioned surface. While they don’t offer the same seamless aesthetic as PIP, they excel in other areas.

The rubber surfacing cost for playground tiles can average around $10 to $15 per square foot total, with individual tiles ranging from $20.00 to $45.00 depending on quantity and gauge. The material alone usually costs between $3 and $8 per square foot. Installation can be as low as $2 per square foot for labor. Tiles are often favored for gyms, uniform play areas, or projects where a DIY component is desired, as they can be easier to install for smaller applications. The ability to replace individual damaged tiles without disturbing the entire surface is a significant advantage, particularly for maintenance in busy community centers in places like Tucson AZ or Nashville TN.

How Rubber Options Compare

When weighing PIP against rubber tiles, look beyond the initial rubber surfacing cost.

- Initial Cost vs. Long-Term Cost: PIP often has a higher upfront installation cost due to the specialized labor and on-site mixing. However, its seamless nature can lead to lower long-term maintenance needs compared to tiles, where individual pieces might shift or require replacement over time. Conversely, for smaller areas or specific applications, tiles might present a more budget-friendly initial outlay.

- Maintenance Requirements: Both options are relatively low maintenance. PIP typically requires regular cleaning and periodic sealing (every few years). Tiles also need cleaning, but individual damaged tiles can be easily removed and replaced, which can be a cost-effective repair strategy.

- Safety Performance: Both PIP and rubber tiles are designed to meet critical fall height requirements and provide excellent shock absorption. PIP offers a continuous, smooth surface, which is beneficial for accessibility and preventing tripping hazards. Tiles, while safe, have seams that can be a minor consideration in some contexts.

- Lifespan: When properly installed and maintained, both poured-in-place rubber and rubber tiles can last approximately 10 to 15 years, or even up to 20 years, offering a significant return on investment compared to traditional loose-fill materials like wood chips or sand.

At Replay Surfacing, we offer all these options in Charlotte NC, Columbia SC, Raleigh NC, Sanford NC, Tucson AZ, Connecticut, Indiana, Nashville TN, Beaverton OR, and Lake Charles Louisiana, ensuring you find the perfect fit for your specific needs and budget.

Key Factors That Influence Your Rubber Surfacing Cost

Understanding the variables that contribute to the overall rubber surfacing cost is crucial for effective budgeting. It’s not just about the per-square-foot price; many elements play a significant role. Let’s dig into what drives these costs.

The complexities of estimating rubber surfacing cost are detailed further in our guide to Rubber Softfall Cost.

Project Size and Total Square Footage

One of the most significant determinants of rubber surfacing cost is the project’s size. Generally, the larger the area, the lower the per-square-foot price due to economies of scale and volume discounts on materials and labor mobilization.

- Volume Discounts: For projects 1,000 sq. ft. or larger, the installed cost can range from $9 to $18 per sq. ft. Larger areas often see volume discounts, dropping the price to $7–$12 per sq. ft.

- Minimum Order Quantities: Smaller projects, while still viable, may incur a higher per-square-foot cost. This is because certain fixed costs, like equipment mobilization, site preparation, and material delivery, are spread over a smaller area. For online orders of PIP, some providers have a minimum of 1100 sq ft. If your project in Connecticut or Indiana is smaller, we encourage you to contact us directly for a custom quote that accounts for these nuances.

Surface Thickness and Fall Height Safety

The thickness of your rubber surfacing directly correlates with its safety performance and, consequently, its rubber surfacing cost. Thicker surfacing provides greater impact attenuation, which is vital for playground safety.

- Critical Fall Height (CFH): Playgrounds require specific thicknesses to meet ASTM F1292-18 safety standards, which dictate how high a child can safely fall onto the surface. For example, it only takes 4.5 inches of poured rubber to allow a child to fall safely from a height of 10 feet. The higher your playground equipment, the thicker the rubber surface needs to be, which adds to the cost.

- Cost Increase: While 1/2″ is standard for some applications, 1″ or more is common for high-traffic playgrounds. Increasing thickness can add $3–$5 per sq. ft. for extra cushioning.

- Layer Breakdown: The aggregate foundation or base layer can range from $3 to $6 per square foot. The PIP top layer (wear layer) typically costs $10 to $15 per square foot, with its thickness directly impacting this price.

Ensuring compliance with local safety codes and ASTM standards is paramount for any playground project in our service areas, from Raleigh NC to Lake Charles Louisiana. You can review the specifics of these standards at ASTM F1292-18 safety standards.

Material Choices: EPDM vs. SBR Rubber

The type of rubber granules used significantly impacts both the durability and the rubber surfacing cost.

- SBR (Styrene-Butadiene Rubber): This is a highly cost-effective option, typically made from recycled tires. SBR granules are usually black and are excellent for the base layer (or cushion layer) of poured-in-place systems due to their shock-absorbing properties and lower cost. We’re proud to transform environmental hazards into safe surfaces using these recycled materials.

- EPDM (Ethylene Propylene Diene Monomer): EPDM is a virgin rubber product, known for its vibrant color stability and superior UV resistance. It’s commonly used for the wear layer (top layer) of poured-in-place systems, especially where aesthetics and long-term color retention are important. EPDM granules are almost four times more expensive than SBR, and custom colors or 100% EPDM wear layers can add an extra $2–$4 per sq. ft. to your rubber surfacing cost.

- Bonding Agents: The choice of bonding agent (the glue that holds the granules together) also affects cost and appearance. Aromatic glue is more cost-effective but can amber or yellow over time due to UV exposure. Aliphatic glue is clear, more expensive, and preferred for lighter colors, especially in splash pads or areas where color purity is critical.

For those interested in sustainable and budget-friendly options, our Bonded Rubber Mulch Price Guide offers more insights.

Design Complexity and Color Selection

While a simple, single-color surface is the most economical, custom designs and vibrant color choices will increase your rubber surfacing cost.

- Standard vs. Custom Colors: Solid black or speckled black recycled rubber is generally more cost-effective. Custom colors or using 100% EPDM granules for vibrant hues can add $2–$4 per sq. ft. to the price.

- Intricate Patterns and Logos: Incorporating intricate patterns, shapes, or logos (e.g., a school mascot in Raleigh NC or a park emblem in Beaverton OR) requires additional labor for precise application and masking, increasing the overall rubber surfacing cost.

- Cost-Saving Tip: Many clients choose to mix their desired EPDM color with black SBR rubber granules for the wear layer. This reduces the amount of expensive EPDM needed, offering a balance between aesthetics and budget.

The desire for a visually appealing and unique surface, such as a custom-designed pool deck, often means a higher investment. Explore more about these options in our Rubber Pool Deck Cost guide.

Site Preparation and Installation

The condition of your existing site is a critical factor in determining the final rubber surfacing cost. A well-prepared sub-base ensures the longevity and performance of the rubber surface.

- Sub-Base Requirements: Rubber surfacing can be installed over various stable sub-bases, including concrete, asphalt, or a properly compacted aggregate (stone) foundation. An aggregate foundation typically costs between $3 and $6 per square foot.

- Grading and Leveling: If your site requires significant grading, leveling, or repairs to an existing surface (like filling cracks in asphalt or concrete), these costs can add 10-20% to the total project price. Proper site preparation is non-negotiable for a durable and safe installation.

- Geographic Location: Labor and material transportation costs can vary by region. While we serve a wide footprint including Charlotte NC, Columbia SC, and Tucson AZ, local market conditions and accessibility to your site can influence the final quote.

- Installation Labor: Certified installers typically charge $4–$8 per sq. ft. for labor. Poured-in-place rubber installation is a specialized process that requires skilled technicians to mix and hand-trowel the material correctly, ensuring a seamless and compliant surface. We never recommend DIY for PIP installations to ensure safety and longevity.

Consider the unique site preparation needs for projects in areas like Lake Charles Louisiana, where humidity might impact curing times, or the varying soil conditions in Connecticut.

Beyond the Price Tag: The Long-Term Value of Rubber Surfacing

While the initial rubber surfacing cost is a significant consideration, focusing solely on the upfront price can lead to overlooking the tremendous long-term value and benefits that rubber surfacing provides. At Replay Surfacing, we see our installations as an investment in safety, durability, and community well-being across all our service locations.

Lifespan and Maintenance: A Look at Long-Term Rubber Surfacing Cost

One of the most compelling arguments for rubber surfacing is its exceptional lifespan and low maintenance requirements, which significantly impact its long-term rubber surfacing cost.

- Typical Lifespan: Poured-in-place rubber surfaces and high-quality rubber tiles are engineered to last between 10 to 15 years, with some installations exceeding 20 years with proper care. This far surpasses the lifespan of traditional playground materials like wood chips, sand, or gravel, which often require annual replenishment and more frequent maintenance.

- Low Maintenance: Unlike loose-fill materials that scatter, compact, or decompose, rubber surfacing stays put. Maintenance typically involves simple cleaning (sweeping, hosing down, or occasional pressure washing) to remove debris. Periodically, a sealant can be applied to renew wear and weather resistance, extending the surface’s life even further. Small damaged areas can often be repaired without needing to replace the entire surface.

- Cost-Effectiveness: When you factor in the avoided costs of annual material replacement, extensive daily raking, and reduced labor for maintenance, rubber surfacing proves to be incredibly cost-effective over its lifespan. In fact, our rubber surfacing solutions can be up to 50% more affordable than asphalt over the product’s lifetime, offering substantial savings for facilities in places like Charlotte NC or Beaverton OR.

This long-term value makes rubber an excellent choice for high-traffic areas. You can see how this plays out in practical applications by reviewing our insights on Recycled Rubber Walkway Prices.

Opening up Value Through Safety, Accessibility, and Sustainability

The true value of rubber surfacing extends far beyond its monetary rubber surfacing cost; it encompasses critical benefits for users and the environment.

- Superior Safety: Rubber surfacing offers unparalleled impact absorption, drastically reducing the risk and severity of injuries from falls. Its inherent slip-resistance, even when wet, makes it an ideal choice for splash pads, pool surrounds, and other water play areas in the warm climates of Tucson AZ or Lake Charles Louisiana. This peace of mind is invaluable for parents, facility managers, and community leaders.

- ADA Compliance and Accessibility: Our seamless poured-in-place rubber surfaces are inherently ADA-compliant, providing smooth, stable, and firm pathways that are easily navigable by wheelchairs, strollers, and those with mobility challenges. This inclusivity ensures that everyone can enjoy play and recreational spaces, aligning with accessibility standards like those found at ADA compliance and accessibility.

- Sustainability and Environmental Benefits: At Replay Surfacing, our core mission is to transform environmental hazards into sustainable solutions. We use millions of pounds of recycled tires, diverting them from landfills and giving them a new, purposeful life as safe surfacing. Choosing our products contributes to a circular economy, reduces your carbon footprint, and can even help facilities qualify for LEED credits, demonstrating a commitment to environmental stewardship in communities from Columbia SC to Nashville TN.

Our projects in Indiana and Connecticut showcase how these benefits translate into vibrant, safe, and sustainable spaces that serve their communities for years to come.

Frequently Asked Questions about Rubber Surfacing Prices

We know you have questions, and we’re here to provide clear, straightforward answers about rubber surfacing cost.

What is the most cost-effective type of rubber playground surfacing?

For poured surfaces, using a higher percentage of black SBR rubber in the wear layer mix can reduce costs. This is because SBR, made from recycled tires, is significantly less expensive than virgin EPDM. While EPDM offers vibrant colors and UV stability, strategically blending it with SBR can provide a colorful aesthetic without the premium price tag of 100% EPDM. For tiles, basic black tiles are often cheaper than colored ones. Overall cost-effectiveness also depends on long-term maintenance, where poured rubber and tiles consistently outperform loose-fill materials like wood chips or sand due to their durability and minimal upkeep. Considering the lifespan and reduced maintenance, the initial rubber surfacing cost for these options often translates into greater savings over time.

How much does the sub-base for rubber surfacing cost?

The foundation is a separate cost from the rubber itself. A properly prepared sub-base is paramount for the longevity and performance of any rubber surface. A compacted aggregate (stone) base can cost between $3 and $6 per square foot, depending on the material’s availability and the site’s preparation requirements. Concrete or asphalt sub-bases will generally be more expensive, but may be necessary depending on existing conditions or specific project needs. A proper sub-base is critical for the longevity of the rubber surface, especially in our service areas like Sanford NC, where varying soil conditions might require specific foundation solutions, or in Tucson AZ, where stable ground is essential for long-term integrity. Neglecting the sub-base can lead to premature surface failure and higher repair costs down the line.

Are there hidden costs I should be aware of?

Yes, it’s wise to budget for additional costs beyond the per-square-foot material price to avoid surprises. These often include:

- Site Preparation: Costs for grading, leveling, debris removal, or repairing an existing substrate (e.g., crack filling in concrete) can add 10-20% to the total.

- Sub-Base Installation: As mentioned, this is often a separate line item.

- Freight Charges: Transporting materials to your location, whether it’s in Charlotte NC or Beaverton OR, will factor into the final price.

- Complex Design Elements: Intricate color designs, custom patterns, or in-laid logos require more labor and specialized materials, increasing the rubber surfacing cost.

- Accessibility Features: While our surfaces are ADA compliant, specific ramps or transitions may add to the overall project.

- Permits and Inspections: Local regulations in places like Columbia SC or Nashville TN may require permits, which come with fees.

We always recommend requesting a detailed, itemized quote that breaks down all components for your project in our service areas. Our team at Replay Surfacing is committed to transparency and helping you understand every aspect of your investment.

Conclusion: Making a Smart Investment in Your Surface

Navigating the rubber surfacing cost can seem complex, but by understanding the key factors involved, you can make an informed decision that prioritizes both budget and long-term value. We’ve explored how project size, surface thickness, material choices (SBR vs. EPDM), design complexity, and site preparation all influence the final price tag.

Choosing rubber surfacing from Replay Surfacing is an investment in durability, safety, and sustainability. While the initial cost may be higher than some traditional options, the extended lifespan, minimal maintenance, and superior safety features translate into significant savings and peace of mind over time. Our commitment to changing recycled tires into safe, resilient surfaces underscores our dedication to both environmental stewardship and community well-being.

Whether you’re planning a new playground in Raleigh NC, a splash pad in Lake Charles Louisiana, or a multi-purpose court in Connecticut, we’re here to help you understand every aspect of your rubber surfacing cost and ensure you get the best solution for your needs.

Learn more about our playground surfacing solutions and let us help you create a vibrant, safe, and sustainable space for your community.