Your Guide to Rubber Crumb Surfacing in Charlotte, NC

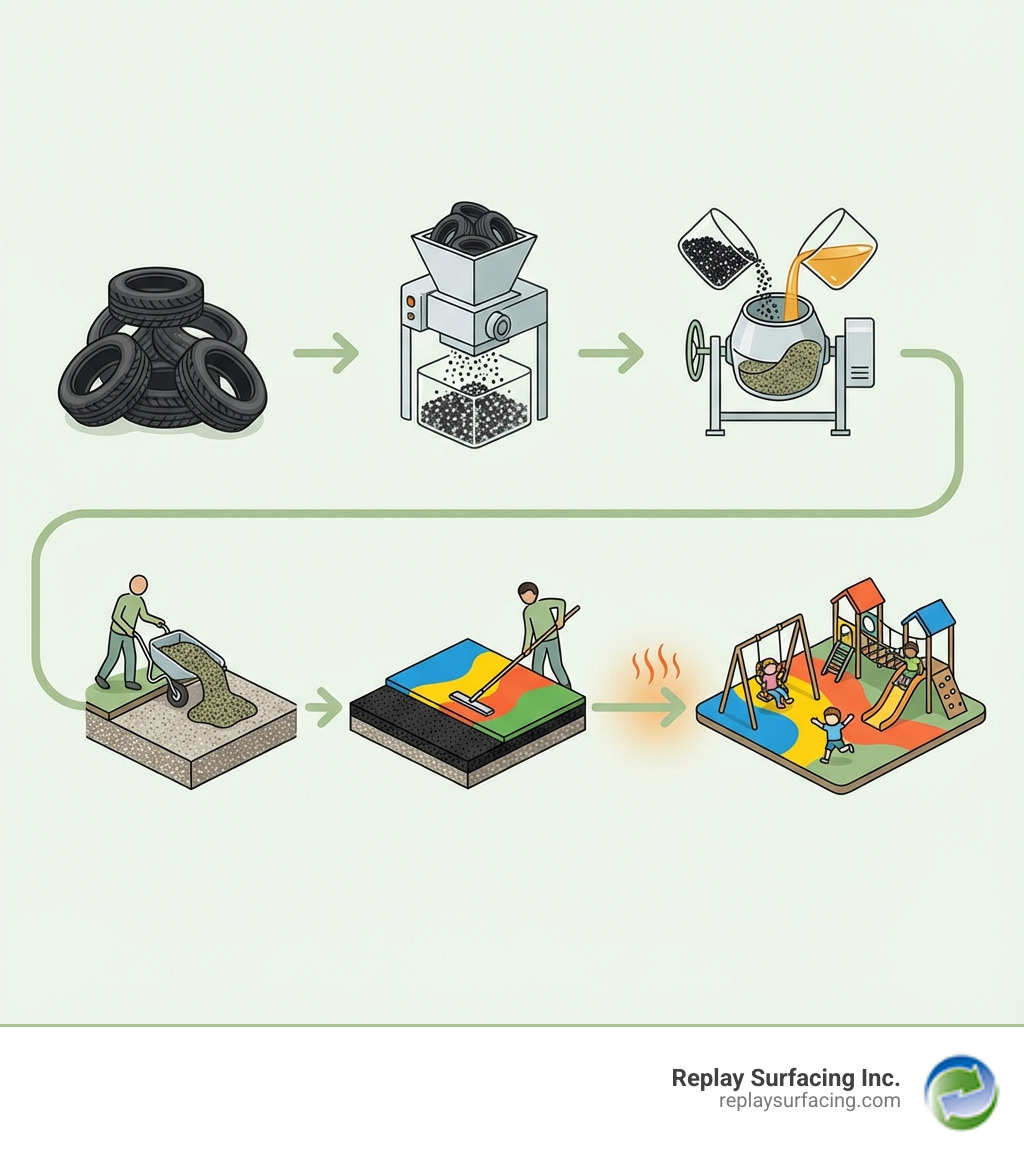

Rubber crumb surfacing in Charlotte, NC, is a durable, shock-absorbent flooring made by mixing recycled tire granules or EPDM rubber with polyurethane binder, then pouring and troweling it onto a prepared base. It’s commonly used for playgrounds, sports fields, pool decks, and walkways because it’s safe, customizable, and environmentally friendly.

Quick Installation Overview:

- Prepare Your Base – Ensure a solid sub-base (concrete or compacted stone) with proper edging

- Choose Your Materials – Select EPDM or SBR rubber crumb and polyurethane binder

- Mix and Pour – Combine materials on-site in the correct ratio

- Trowel Smooth – Spread evenly to your desired thickness (minimum 20mm on hard base, 40mm on stone)

- Cure and Enjoy – Allow 48 hours for the surface to fully set

This versatile material transforms recycled tires into safe, attractive surfaces that last 7-12 years with proper maintenance. Studies show that rubber crumb surfaces offer excellent impact absorption and no consistent difference in injury rates compared to natural turf. The surface is also SUDS compliant, meaning it helps manage drainage and reduces flood risk.

Whether you’re installing a playground that needs to meet specific Critical Fall Height standards or creating a slip-resistant pool deck, rubber crumb surfacing delivers on safety, durability, and aesthetics. It comes in 16+ colors, requires minimal maintenance (just regular sweeping and occasional washing), and keeps millions of pounds of tires out of landfills.

I’m Landon Olson, and as the operator of Replay Surfacing, I’ve dedicated my career to recycling scrap tires into high-quality rubber crumb surfacing solutions for playgrounds, sports facilities, and commercial spaces across North America. My background in mechanical engineering and sustainability helps me apply proven installation principles to deliver safe, long-lasting surfaces that meet both safety standards and environmental goals.

Rubber crumb surfacing vocab to learn:

Step 1: Preparing Your Site for Installation

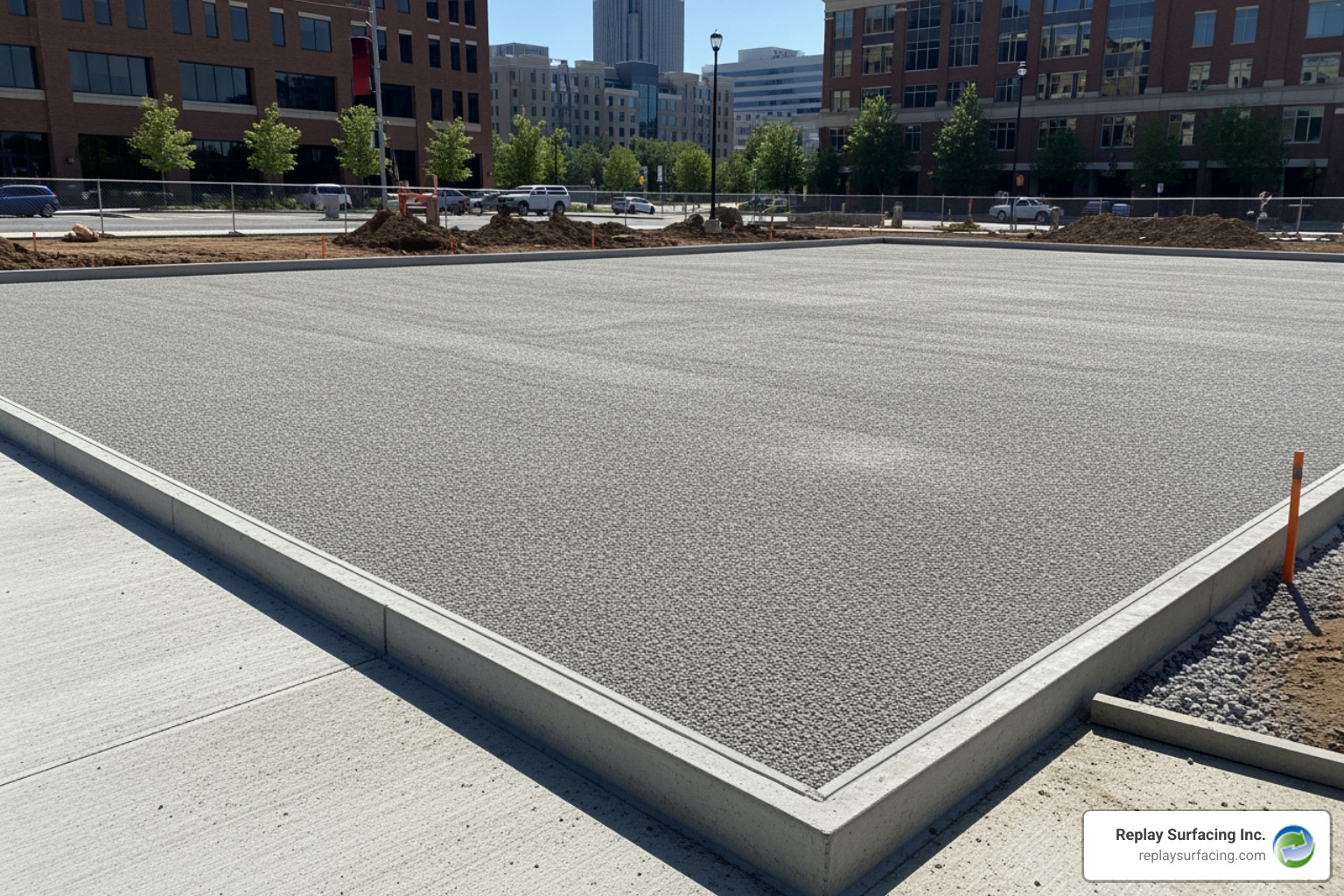

Before we even think about mixing our colorful rubber crumb, the foundation of any successful installation lies in meticulous site preparation. Think of it as building a house – you wouldn’t start framing before laying a solid slab, right? The same principle applies here. A properly prepared sub-base is crucial for the longevity, stability, and safety of your new rubber crumb surfacing.

Sub-Base and Edging Fundamentals

Our first task is to ensure the sub-base is sound. We recommend either a concrete base or a well-compacted stone base. These provide the stability needed to prevent future shifting or cracking. For a surface installed on a hard standing, such as concrete or tarmac, the minimum thickness of the wet pour rubber system should be 20 mm or more. If we’re installing on a compacted stone base, we’re looking for a minimum thickness of 40 mm. This thicker base layer on compacted stone accounts for greater potential movement and ensures adequate shock absorption.

Proper drainage is another non-negotiable. Our rubber crumb surfacing is permeable and often SUDS compliant, meaning it allows water to drain through, reducing runoff and flood risk. However, the sub-base itself should also be designed to facilitate drainage, preventing water from pooling underneath and compromising the surface’s integrity. Good sub-base preparation ensures that water can permeate through the rubber and then effectively drain away, keeping the surface dry and extending its life.

Finally, we need to create a solid perimeter. This means securing the edges of our installation area with timber or PC (pre-cast concrete) edging. This provides a containment barrier for the wet-pour mixture during installation and protects the edges of the finished surface from wear and tear. It’s like framing a beautiful picture – the frame defines and protects the art. For those looking to tackle DIY playground flooring projects, these fundamental steps are key to a professional-looking and durable result.

Calculating Your Material Needs

Once our site is prepped and edged, it’s time to crunch some numbers. We need to accurately calculate the surface area to determine how much rubber crumb and binder we’ll need. Multiply the length by the width of your area to get the square footage.

Next, we consider the depth. This is especially critical for playgrounds, where fall height requirements dictate the thickness of the safety surfacing. This is known as the Critical Fall Height (CFH). Our surfaces can be padded to meet specific fall height requirements, ensuring maximum safety for children. We’ll need to know the highest point a child could fall from to specify the appropriate depth.

With the area and depth determined, we can calculate the total material quantity. The research shows that a typical loss of material can occur during installation and over time, so it’s always wise to factor in a small buffer. We’ll also need to consider the binder-to-crumb ratio, which is crucial for the surface’s strength and flexibility. This ratio will vary slightly depending on the specific product and desired outcome. For a deeper dive into these calculations and how they impact your budget, check out our Playground Rubber Flooring Price Complete Guide.

Essential Tools for a DIY Rubber Surfacing Project:

- Measuring Tape: For accurate site dimensions.

- Level: To ensure an even sub-base.

- Edging Material: Timber or PC edging.

- Mixing Drill with Paddle Attachment: For thoroughly combining crumb and binder.

- Large Mixing Buckets or Tubs: To prepare batches of material.

- Trowels (flat and notched): For spreading and smoothing the rubber mixture.

- Hand Roller or Weighted Roller: For compacting the surface.

- Solvent (e.g., mineral spirits): For cleaning tools and as a trowel lubricant.

- Gloves and Safety Goggles: Essential personal protective equipment.

- Rake or Spreader: For initial distribution of the mix.

Step 2: Selecting the Right Rubber Crumb and Binder

Now that our site is perfectly prepared, it’s time to talk about the stars of the show: the rubber crumb and the binder. The choices we make here will significantly impact the look, feel, durability, and lifespan of our new surface. It’s a bit like choosing the right ingredients for a gourmet meal – quality matters!

Understanding Your Rubber Crumb Surfacing Options

When it comes to rubber crumb surfacing in Charlotte, NC, we primarily work with two types of granules: EPDM and SBR.

-

EPDM (Ethylene Propylene Diene Monomer) rubber is a synthetic, virgin rubber. It’s renowned for its vibrant, fade-resistant colors (we offer 16+ options!), excellent UV stability, and superior resistance to extreme temperatures, weather conditions, and chemicals. EPDM’s robust nature means it has high resistance to tears and other damage, making it ideal for the top, visible layer of our surfaces, especially in areas with high sun exposure like Tucson, AZ, or the humid climates of Lake Charles, LA. EPDM can make a surface last significantly longer, often extending its lifetime from 2-5 years to 7-12 years. Our EPDM Rubber Playground surfaces are a testament to this durability and aesthetic appeal.

-

SBR (Styrene-Butadiene Rubber), often referred to as recycled tire rubber or crumb rubber, is exactly what it sounds like – granules salvaged from old scrap tires. This material forms the resilient, shock-absorbing base layer of many of our installations. It’s highly cost-effective and provides excellent impact attenuation. While SBR is incredibly durable and can withstand significant wear, it typically comes in black or a limited range of darker colors and has less UV stability than EPDM. Using SBR for the base layer is a fantastic way to use recycled materials, contribute to sustainability, and keep costs down without compromising safety. You can learn more about how we transform discarded tires into these valuable resources in our Recycled Rubber Chips Complete Guide.

Here’s a quick comparison to help us decide:

| Feature | EPDM Rubber | SBR Crumb Rubber |

|---|---|---|

| Durability | Very high; resistant to tears, weather, chemicals | High; durable for impact absorption |

| Cost | Higher, due to virgin material and superior properties | Lower, as it’s made from recycled tires |

| Color Variety | Extensive (16+ vibrant colors), UV stable | Limited (mostly black/darker shades), less UV stable |

| UV Resistance | Excellent; fade-resistant | Moderate; can fade over time |

| Primary Use | Top wear layer, visible surface | Base shock-absorbing layer |

Choosing a High-Quality Polyurethane Binder

The binder is the unsung hero of our rubber crumb surfacing. It’s the glue that holds everything together, literally! We use a high-quality, single-component, moisture-cured polyurethane binder. This binder is typically based on MDI (diphenylmethane diisocyanate) prepolymer, which ensures a strong, flexible, and long-lasting bond. Once cured, the chemicals in these binding agents are considered inert, posing minimal health risks.

The quality of this binder directly affects the surface’s overall performance and longevity. Just as EPDM can extend the life of your surface, a premium binder ensures that our rubber crumb surfacing remains cohesive and resilient for years to come. When planning your project, especially in areas like Raleigh, NC, or Nashville, TN, where humidity and temperature can vary, it’s important to consider the weather conditions during application, as moisture plays a role in the curing process. For certain applications, such as resin-bound rubber crumb surfaces, the binder is specifically formulated to create a solid, permeable surface.

Step 3: The Wet-Pour Installation Process for Rubber Crumb Surfacing

With our site prepped and our materials selected, we’re ready for the exciting part: bringing our rubber crumb surfacing to life! The wet-pour method is where the magic happens, changing loose granules into a seamless, resilient surface.

Mixing Your Materials to Perfection

The key to a successful wet-pour installation lies in consistent and precise mixing. Our rubber chippings typically come in handy-sized 20kg poly bags, which makes handling and mixing on-site much easier. We’ll combine the rubber crumb (SBR for the base, EPDM for the top layer) with the polyurethane binder in a specific ratio. This ratio is critical – too much binder, and the surface can become too hard; too little, and it won’t bond properly, leading to premature breakdown.

We use mechanical mixers to ensure every granule is thoroughly coated with the binder, creating a homogenous mixture free of clumps. This meticulous mixing process ensures uniform density and optimal performance across the entire surface. Safety is paramount during this stage, so we always wear appropriate personal protective equipment, including gloves and eye protection. For those interested in the details of the wet-pour technique, our guide on Wetpour Rubber Surfacing offers more insights.

Pouring and Troweling for a Seamless Finish

Once mixed, the material needs to be applied quickly and efficiently. We begin by pouring the mixture onto the prepared sub-base, starting with the SBR base layer if we’re doing a two-layer system. This base layer acts as the shock pad, providing the primary impact absorption. After the base layer is evenly distributed and compacted (if applicable), we apply the EPDM wear layer.

Our skilled installers then use specialized trowels to spread and level the rubber crumb surfacing to achieve a smooth, seamless finish with consistent thickness. Trowel lubricant is often used to prevent the rubber from sticking to the tools, ensuring a professional, unblemished appearance. This manual process allows us to create intricate patterns, logos, and custom designs directly into the surface, adding aesthetic appeal and functionality. Imagine a vibrant hopscotch pattern on a playground in Charlotte, NC, or a school logo subtly integrated into a sports surface in Nashville, TN! This level of customization is a significant advantage of poured-in-place rubber. For more on creating these fantastic surfaces, check out our guide to Poured in Place Rubber The Ultimate Playground Safety Surface.

The surface then needs to cure, which typically takes about 48 hours to solidify. During this time, it’s crucial to keep traffic off the newly laid surface to allow the binder to fully set and achieve its maximum strength.

Step 4: Post-Installation Care and Safety Benefits

After the final trowel stroke and the curing process is complete, our vibrant new rubber crumb surfacing is ready to be enjoyed! But our commitment to quality doesn’t end there. Understanding proper care and the inherent safety benefits of this material is crucial for maximizing its lifespan and ensuring continued user safety.

Maintenance for Long-Lasting Durability

One of the great advantages of rubber crumb surfacing in Charlotte, NC, is its low maintenance requirement. Unlike traditional materials that might require frequent weeding, raking, or patching, our surfaces are designed for durability. Regular sweeping or blowing away loose debris is usually all that’s needed to keep them looking fresh. For a deeper clean, a gentle wash with warm soapy water and a soft brush is sufficient. It’s important to avoid harsh chemicals like bleach or strong degreasers, as these can damage the rubber and binder.

Our surfaces don’t freeze, blow away, compress, erode, or decompose like some loose-fill options. They are also clean, meaning they won’t bleed colors or harbor pests. Spot repairs are relatively easy if minor damage occurs, which helps extend the overall lifespan. We also recommend seasonal checks to ensure everything is in top condition, especially after extreme weather. For more detailed insights into maintaining your rubber surfaces, our article on The Pros and Cons and Recycled Rubber Walkways provides valuable tips. With proper care, your rubber crumb surfacing can comfortably last 7-12 years, providing a beautiful and safe environment for years to come.

Understanding the Safety and Health Aspects

Safety is at the core of why we advocate for rubber crumb surfacing, especially for playgrounds and sports fields. The material’s inherent elasticity provides excellent impact absorption, significantly reducing the risk of injuries from falls. This is known as fall attenuation, and our surfaces can be designed to meet specific Critical Fall Height (CFH) ratings, ensuring compliance with safety standards for playground equipment. Furthermore, the textured nature of the surface offers superior non-slip properties, even when wet, making it an ideal choice for pool decks in sunny Tucson, AZ, or splash pads in Sanford, NC. Our Shock Absorbing Playground Surfaces are specifically designed with this in mind.

We understand that health concerns regarding recycled rubber have been raised in the past. We want to assure you that extensive research has consistently indicated a low potential for chemical exposure from rubber crumb surfacing. Studies, including those cited by the New York State Department of Health and federal research, have found no consistent differences in injury rates between natural and crumb-rubber infilled synthetic turf, and that the potential for chemical exposures is low. For instance, studies by Janes et al. (2018) found no determined health risk from ingestion or dermal contact with poured-in-place surfaces on playgrounds for children. They also noted that chemicals in cured binding agents are inert and pose minimal health risks.

While some older synthetic turf fibers did contain liftd lead levels, newer products, like those we provide, are manufactured without such concerns. The potential for inhalation exposure is generally insignificant and not different from natural turf fields. We continuously monitor and adhere to the latest research and guidelines to ensure our products meet the highest safety and health standards. For comprehensive information, we encourage you to review the Scientific research on injury rates on different surfaces and the Federal research on recycled tire crumb. We believe in providing surfaces that offer both peace of mind and endless fun, which is why we also address concerns in our guide Is Rubber Mulch a Safe Surface for Your Childs Playground.

Step 5: Advanced Considerations for Your Project

As we wrap up our guide, let’s explore some advanced considerations that can lift your rubber crumb surfacing project from functional to truly exceptional. This is where we blend practicality with personality, ensuring your surface not only performs flawlessly but also reflects your unique vision.

Releasing Your Creativity with Design

One of the most exciting aspects of rubber crumb surfacing is the incredible design flexibility it offers. With a wide palette of colors, we can transform any space into a vibrant, engaging environment. Imagine a playground in Columbia, SC, adorned with custom color combinations, educational elements like hopscotch, number grids, or even letter grids. We can integrate custom logos for schools or businesses, creating a truly unique and branded surface. Our ability to pour the material in any shape or design means there’s virtually no limit to what we can create. This allows us to make playgrounds not just safe, but also interactive and stimulating, reinforcing classroom learning through play. Explore the possibilities with our Colored Rubber Surfaces for Playgrounds.

Environmental and Sustainability Factors

At Replay Surfacing, our mission is deeply rooted in sustainability. Every project we undertake contributes to a greener future. We recycle millions of tires annually, diverting them from landfills where they pose significant environmental hazards, including the risk of toxic tire fires. By changing these waste tires into high-quality rubber crumb surfacing, we’re not just creating safe surfaces; we’re actively reducing landfill waste and preventing pollution.

Our surfaces are also permeable, allowing water to drain through, which supports healthy ecosystems and reduces the strain on stormwater systems. This commitment to environmental responsibility means that choosing our products can even contribute to LEED credits for sustainable construction materials. We’re proud to be part of the solution, turning an environmental challenge into a valuable resource. For more on the broader impact of recycled rubber, dig into the Environmental Impacts of Recycled Rubber and learn about Sustainable Construction Materials.

When considering local installation services in areas like Charlotte, NC, Columbia, SC, Raleigh, NC, Sanford, NC, Tucson, AZ, Connecticut, Indiana, Nashville, TN, Beaverton, OR, or Lake Charles, LA, you’re choosing a partner committed to both exceptional quality and environmental stewardship.

Conclusion: A Professional Finish for Your Space

We’ve journeyed through the entire process of installing rubber crumb surfacing in Charlotte, NC, from preparing the ground beneath our feet to selecting the perfect blend of materials and bringing vibrant designs to life. We’ve seen how this remarkable material transforms recycled tires into incredibly safe, durable, and aesthetically pleasing surfaces that benefit both people and the planet.

The benefits are clear: superior safety with excellent impact absorption and non-slip properties; exceptional durability with a lifespan of 7-12 years and minimal maintenance; endless aesthetic possibilities through custom colors and designs; and a strong commitment to sustainability by recycling millions of tires.

By following this guide, you can confidently install a high-quality, long-lasting rubber crumb surfacing that provides a safe and attractive environment for years to come. For professional-grade materials and expert advice for your next project, explore our playground surfacing solutions.