Why Recycled Playground Surface Safety and Sustainability Matter

A recycled playground surface transforms millions of discarded tires into safe, durable play environments that protect children while protecting our planet. These innovative surfaces offer superior safety performance, environmental benefits, and long-term cost savings compared to traditional playground materials.

Key Benefits of Recycled Playground Surfaces:

- Safety: Superior impact absorption and fall height protection up to 12 feet

- Sustainability: Diverts 290 million scrap tires annually from landfills

- Durability: 10-15 year lifespan with minimal maintenance

- Accessibility: ADA-compliant unitary surfaces for wheelchair access

- Cost-Effective: Lower long-term costs due to reduced maintenance needs

As parents, facility managers, and communities across Charlotte, Raleigh, and Tucson increasingly prioritize both child safety and environmental responsibility, understanding recycled playground surfaces becomes essential. These surfaces use 100% recycled tire rubber combined with safe polyurethane binders to create impact-absorbing surfaces that cushion falls while eliminating the need for constant refilling like traditional wood chips or sand.

The change from environmental hazard to playground safety surface represents a remarkable innovation. The EPA reports that about 290 million scrap tires are generated in the U.S. annually, and recycled rubber flooring requires less energy than creating new rubber products, resulting in lower overall carbon emissions.

I’m Landon Olson, a mechanical engineer and MBA who operates Replay Surfacing, where we specialize in recycling millions of pounds of scrap tires into high-quality recycled playground surface solutions. My experience spans manufacturing, sustainability, and safety surfacing, combining engineering principles with sustainable business practices to create safer play environments.

Key recycled playground surface vocabulary:

The Rise of the Recycled Playground Surface

Picture this: 290 million scrap tires pile up across America every year. That’s enough rubber to circle the earth several times! Instead of letting these tires sit in landfills creating environmental headaches, we at Replay Surfacing saw an incredible opportunity. We transform these discarded tires into beautiful, safe recycled playground surface solutions that kids love and parents trust.

The environmental wins are huge when you choose recycled rubber surfacing. Every playground we install diverts thousands of tires from landfills, giving them a meaningful second life where children can play safely. But the benefits go way beyond just reducing waste.

Manufacturing recycled rubber flooring uses significantly less energy than creating new rubber from scratch. This means fewer carbon emissions floating around in the air our kids breathe. In water-conscious areas like Tucson, families especially appreciate that our recycling process conserves precious water resources compared to traditional manufacturing.

The change from roadside hazard to colorful playground is honestly pretty amazing to watch. You can see the fascinating process of turning tires into playgrounds in action. Our comprehensive Recycled Tire Playground Flooring options prove that sustainability and safety make perfect partners.

From Charlotte’s humid summers to Raleigh’s changing seasons, from Columbia’s community parks to the desert playgrounds of Tucson, we’re creating eco-conscious play environments that serve both children and the planet. Every installation represents millions of pounds of tires that found their purpose instead of becoming tomorrow’s environmental problem.

Primary Types of Recycled Playground Surface Materials Offered by Replay Surfacing Inc.

When families across Connecticut, Indiana, and Oregon visit their local playgrounds, they’re walking on one of three main types of recycled playground surface materials we specialize in. Each option brings unique advantages depending on your specific needs and vision.

Poured-in-Place (PIP) Rubber creates the most stunning and versatile surfaces you’ll find anywhere. Think of it as a custom canvas for creativity – we can design anything from simple color patterns to elaborate graphics that bring playgrounds to life. The system uses two layers: a shock-absorbing base made from 100% recycled tires, topped with a durable wear layer that delivers those vibrant colors kids gravitate toward.

The seamless nature means no loose pieces to scatter or create tripping hazards. Whether you’re planning a playground in snowy Indiana or sunny Tucson, PIP rubber delivers consistent safety performance year-round. Our Poured-in-Place Rubber: The Ultimate Playground Safety Surface guide shows exactly why this option leads the industry.

Rubber Tiles offer the perfect balance of performance and practicality. These interlocking squares install like puzzle pieces, making them ideal for DIY-friendly projects or situations where future modifications might be needed. Each tile provides excellent shock absorption while maintaining the durability that recycled rubber is known for.

The modular design means if one section gets damaged, you can replace just that tile instead of resurfacing the entire area. Available in multiple colors and thicknesses, these tiles adapt to any design vision while meeting strict safety standards. Our Non-Toxic Playground Tiles ensure families get both safety and peace of mind.

Bonded Rubber Mulch delivers the natural appearance many communities prefer with none of the maintenance headaches. This innovative surface looks like traditional wood mulch but stays exactly where you put it. No more weekly raking, no annual top-offs, and no bare spots developing under swings.

The porous design allows water to drain through easily, preventing puddles that plague traditional surfaces. From Beaverton’s wet seasons to the occasional desert downpours in Tucson, bonded rubber mulch keeps playgrounds accessible and safe in all weather conditions.

From Scrap Tire to Safe Surface: The Recycling Process

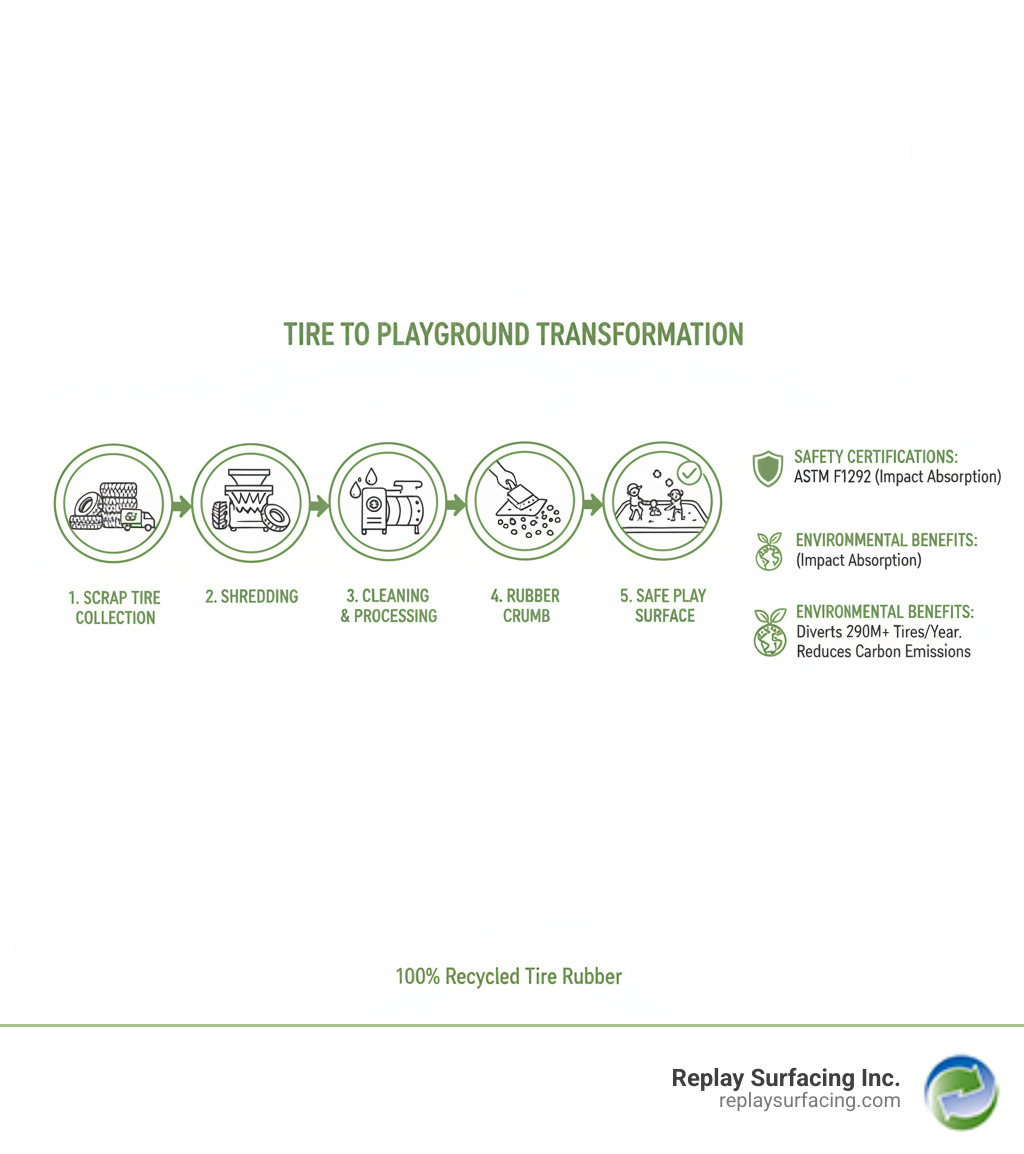

The journey from discarded tire to vibrant recycled playground surface involves precision, technology, and a commitment to safety that we take seriously at Replay Surfacing. Every surface we install across our service areas represents this carefully controlled change process.

Tire collection begins the process, with millions of scrap tires gathered from tire shops, recycling centers, and municipal programs. Instead of these tires becoming mosquito breeding grounds or fire hazards, they become raw material for something wonderful.

The shredding process breaks tires down into manageable pieces using powerful mechanical shredders or cryogenic freezing techniques. Cryogenic processing freezes tires to extremely cold temperatures, making them brittle enough to shatter into clean, uniform pieces.

Steel and fiber removal requires sophisticated equipment to separate the rubber from tire belts and textile fibers. Industrial magnets extract ferrous metals while screening systems remove fabric fibers. The goal is achieving wire-free rubber with metal content below 0.01% – critical for playground safety.

Cleaning and processing ensures the rubber meets our strict purity standards. Multiple wash cycles remove contaminants, dirt, and debris until the material is environmentally inert and completely safe for children’s play areas.

Crumb rubber creation produces the foundation material for all our surfaces. This processed rubber comes in various sizes, each engineered for specific applications. Whether destined for a playground in Charlotte or a splash pad in Columbia, every batch meets identical quality standards.

Finally, polyurethane binders transform loose crumb rubber into unified surfaces. These specialized binders are UV-stabilized, VOC-free once cured, and designed to withstand everything from Indiana winters to Arizona summers. The result is a resilient, impact-absorbing surface that protects children while protecting the environment for years to come.

Safety and Accessibility: A Head-to-Head Comparison

Choosing the right playground surface is a critical decision that impacts child safety, accessibility, and long-term maintenance. At Replay Surfacing, we’ve seen how our recycled playground surface solutions outperform traditional loose-fill materials across key metrics. Let’s compare them:

| Feature | Recycled Rubber (PIP, Tiles, Bonded Mulch) “`

Introduction

Picture this: millions of old tires that would normally sit in landfills are instead transformed into vibrant, safe playgrounds where children laugh and play. That’s the magic of a recycled playground surface – turning what was once an environmental problem into a solution that protects both kids and our planet.

These innovative surfaces aren’t just good for the environment. They actually outperform traditional playground materials in almost every way. A recycled playground surface provides superior impact absorption that can protect children from falls up to 12 feet high, while diverting 290 million scrap tires annually from landfills across America.

What really excites parents and facility managers in Charlotte, Raleigh, Tucson, and beyond is the long-term value. These surfaces last 10-15 years with minimal maintenance – no more weekly trips to add fresh wood chips or rake scattered sand. They’re also ADA-compliant, creating firm, stable surfaces that wheelchairs can easily steer, making playgrounds truly accessible for all children.

The change from environmental hazard to playground safety is remarkable. The EPA tells us that about 290 million scrap tires pile up in the U.S. every year. Instead of letting them become breeding grounds for mosquitoes or fire hazards, we use 100% recycled tire rubber combined with safe polyurethane binders to create surfaces that cushion falls and stay put through every season.

I’m Landon Olson, and as a mechanical engineer and MBA, I’ve seen how engineering meets sustainability at Replay Surfacing. We specialize in recycling millions of pounds of scrap tires into high-quality recycled playground surface solutions throughout our service areas. It’s incredibly rewarding to combine engineering principles with sustainable business practices, knowing that every playground we create makes communities safer while helping our environment.

Whether you’re exploring options like loose rubber mulch, resin bound rubber crumb, or epdm rubber playground surfaces, you’re making a choice that benefits children today and the world they’ll inherit tomorrow.

The Rise of the Recycled Playground Surface

At Replay Surfacing, we believe creating safe play environments for children should go hand-in-hand with protecting the planet they’ll inherit. That’s why we’re passionate about recycled playground surface solutions that make a real difference for communities across Charlotte, Raleigh, and beyond.

The environmental benefits of choosing recycled rubber are truly remarkable. Every year, approximately 290 million scrap tires pile up across the U.S., often ending up in landfills where they create environmental hazards and take up valuable space. By changing these discarded tires into playground surfaces, we’re giving them a meaningful second life while solving a massive waste problem.

Here’s what makes this change so powerful: using recycled rubber requires significantly less energy than manufacturing new rubber products from scratch. This energy reduction translates directly into lower carbon emissions, contributing to cleaner air for our children. In water-conscious areas like Tucson, AZ, the process also uses considerably less water than traditional manufacturing methods.

The journey from scrap tire to vibrant playground surface truly showcases human ingenuity at work. You can see this fascinating change by watching the fascinating process of turning tires into playgrounds. Our comprehensive Recycled Tire Playground Flooring options meet the highest safety and sustainability standards for communities throughout our service areas.

Primary Types of Recycled Playground Surface Materials Offered by Replay Surfacing Inc.

When designing a safe and engaging play space, the type of recycled playground surface you choose makes all the difference. We offer three main options, each with unique benefits custom to different needs and preferences for playgrounds across North Carolina, South Carolina, Arizona, and beyond.

Poured-in-Place (PIP) Rubber stands out as our most versatile and visually stunning option. This seamless surface creates unlimited design possibilities with vibrant colors, intricate patterns, and custom graphics. The system features two layers: a colorful top wear layer made from non-toxic EPDM rubber, and a shock-absorbing base layer crafted from 100% recycled tires.

What makes PIP special is its ability to conform to any playground layout. It flows over slopes, mounds, and contours while maintaining consistent safety performance across the entire play area. Since nothing displaces or shifts, children enjoy reliable protection whether they’re playing in Charlotte’s summer heat or Columbia’s spring showers. Learn more about Poured-in-Place Rubber: The Ultimate Playground Safety Surface.

Rubber Tiles offer a practical, modular solution that’s often perfect for DIY installations. These pre-fabricated tiles interlock seamlessly and can be easily replaced if needed, making them ideal for smaller community playgrounds or backyard play areas. They’re engineered with various thicknesses to meet specific fall height requirements while offering excellent shock absorption.

The beauty of tiles lies in their flexibility and range of colors, giving you design options without the complexity of a poured system. Our Non-Toxic Playground Tiles provide reliable safety performance that families can trust.

Bonded Rubber Mulch combines the natural appearance of traditional wood mulch with superior safety and durability. This innovative surface consists of shredded recycled rubber mixed with polyurethane binder, creating a unified yet porous surface that looks like loose mulch but stays exactly where you put it.

The porous design allows water to flow through easily, preventing puddles that can interrupt playtime. This feature proves especially valuable in areas like Louisiana with frequent rainfall, ensuring year-round playability. Bonded rubber mulch installs in a single step and creates a firm yet comfortable surface that’s much easier to walk and run on than conventional sand or wood chips.

From Scrap Tire to Safe Surface: The Recycling Process

The change of a discarded tire into a safe, vibrant recycled playground surface represents modern recycling technology at its finest. At Replay Surfacing, we’ve perfected this process to ensure the highest quality and safety standards for playgrounds throughout our service areas.

The journey begins with tire collection from various sources, preventing millions of tires from accumulating in landfills or becoming pest breeding grounds. Once collected, these tires undergo a rigorous shredding process using either powerful mechanical shredders or cryogenic freezing that shatters tires into smaller, uniform pieces.

During shredding, we carefully execute steel and fiber removal. Since tires contain steel belts and textile fibers, powerful magnets extract all ferrous metals while sophisticated screening systems remove fibers. This meticulous separation ensures the final rubber product is pure and playground-safe, with metal content typically less than 0.01%.

The cleaning and processing stage follows, where materials undergo thorough washing to remove contaminants, dirt, and debris. This critical step ensures the final product remains non-toxic and environmentally safe. The cleaned rubber then gets processed into various sizes, creating the crumb rubber that forms the foundation of our playground surfaces.

For unitary surfaces like Poured-in-Place rubber and bonded rubber mulch, we mix the crumb rubber with specially formulated polyurethane binders. These binders are engineered to be durable, UV-stabilized, and free of harmful VOCs once cured. The binder bonds rubber particles together, creating resilient, impact-absorbing surfaces that withstand years of play and weather conditions from Tucson’s intense sun to Indiana’s snowy winters.

This careful process ensures our recycled playground surfaces deliver both environmental responsibility and exceptional safety performance for children across all our service areas.

Safety and Accessibility: A Head-to-Head Comparison

Choosing the right playground surface is a critical decision that impacts child safety, accessibility, and long-term maintenance. At Replay Surfacing, we’ve seen how our recycled playground surface solutions outperform traditional loose-fill materials across key metrics. Let’s compare them:

| Feature | Recycled Rubber (PIP, Tiles, Bonded Mulch)