Impact of EPDM Quality on Long-Term Fall Attenuation in PIP Surfaces

How EPDM Quality Affects Fall Attenuation

High-quality EPDM in PIP surfacing plays a major role in fall attenuation in PIP surfaces, directly impacting playground safety:

- Offers higher UV stability of EPDM playground surfacing, keeping granules flexible and preventing brittleness.

- Holds its elastic rebound for more years, helping the surface absorb impact energy effectively.

- Maintains color stability, which often correlates with less chemical breakdown and micro-cracking.

Lower-quality EPDM (cheaper fillers, regrind, poor pigment stability):

- Hardens and shrinks faster under sun and temperature changes.

- Loses its ability to compress and recover, leading to higher G-max and HIC values sooner.

- More prone to surface granule loss, exposing the base layer faster, which drastically reduces fall attenuation.

Long-Term Performance Trends of PIP Surfaces

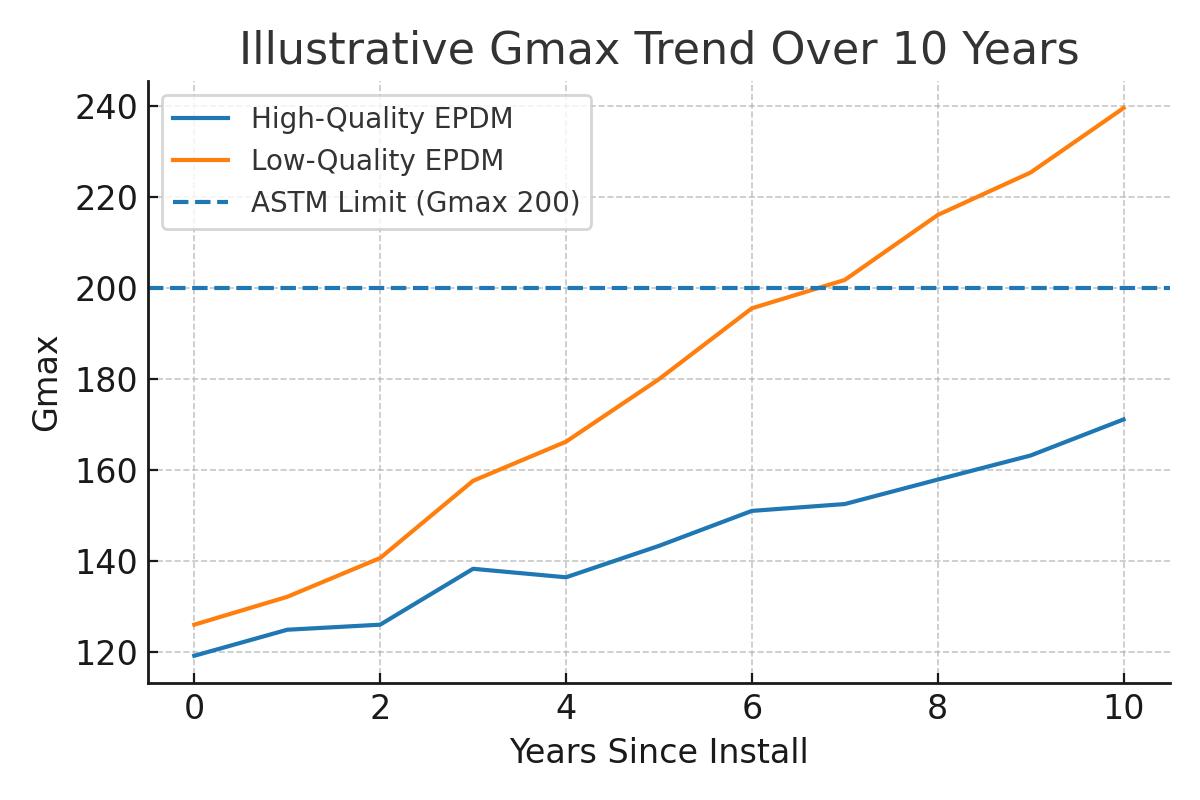

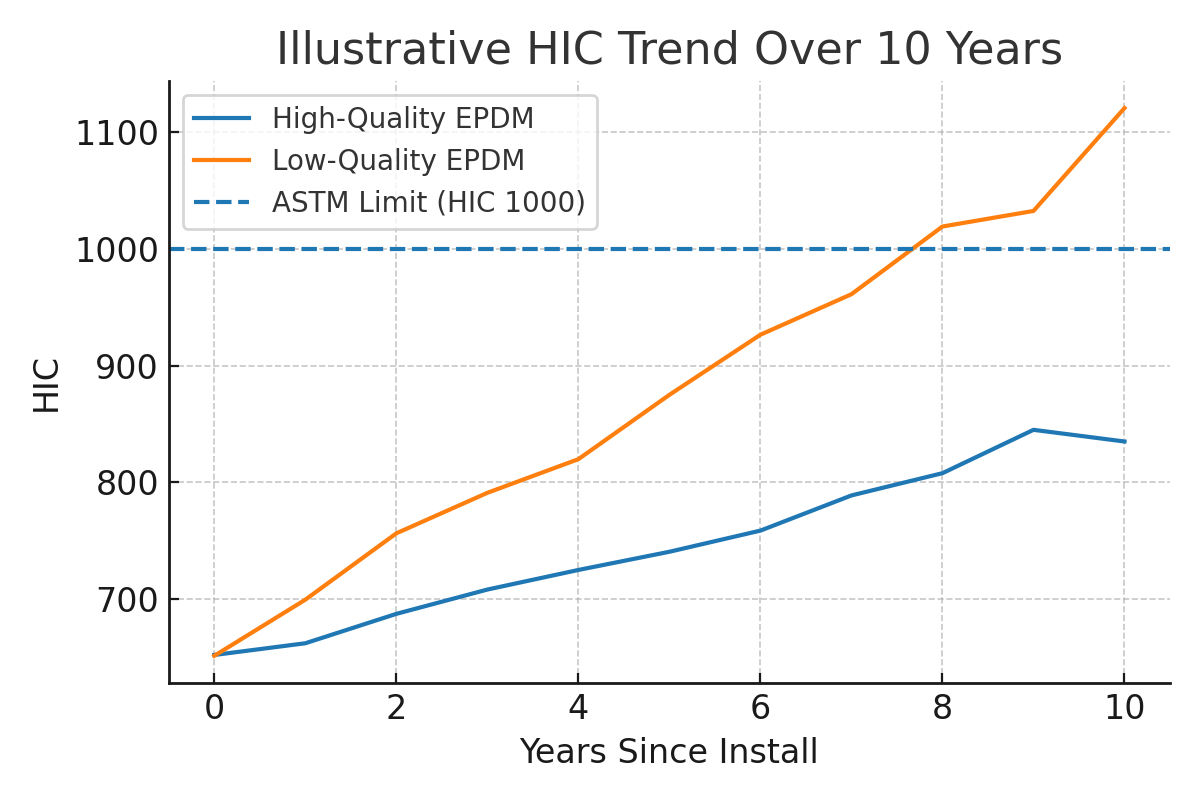

- Year 0–2: Most EPDM—high or low quality—performs similarly after installation if mixed with the right binder ratio.

- Years 3–5: Premium EPDM still meets safety testing for playground flooring (ASTM F1292, EN 1177), while low-grade EPDM often fails in high-wear areas.

- Year 6–10: High-quality EPDM, if installed over a good base and maintained, can still meet fall attenuation with only localized repairs. Low-quality EPDM usually has widespread hardening and base exposure, requiring a full re-top much sooner.

Real-World Example of EPDM Quality in Playground Safety

If two playgrounds are installed identically except for EPDM quality:

- Premium EPDM: May keep G-max < 200 and HIC < 1000 for 8–10 years with basic long-term maintenance of playground surfacing.

- Low-grade EPDM: May fail safety tests in as little as 3–4 years, even if visually intact, because the top layer has hardened and lost elasticity.

Bottom Line

Quality EPDM:

- Costs more upfront but extends the period before expensive repairs.

- Maintains safety compliance longer, reducing liability risks.

- Delivers better total cost of ownership over the surface’s life.

Low-quality EPDM:

- Saves on initial cost but almost always increases life-cycle cost and safety risks.

Illustrative 10-Year Fall Attenuation Trends (NOT lab data)

The following charts are illustrative and show potential divergence between high-quality and low-quality EPDM over 10 years, assuming identical base, thickness, and binder.

Evidence Behind the Claims

Standards & Field Reality:

- ASTM F1292 and EN 1177 set performance limits (Gmax ≤ 200, HIC ≤ 1000) for playground safety.

- A multi-site longitudinal study of U.S. playgrounds documented PIP areas falling out of compliance in use zones over time.

- Temperature variations alone can affect HIC, showing material condition affects impact response.

Why EPDM Quality Matters for Fall Attenuation

High-quality EPDM:

- Costs more upfront but maintains fall attenuation in PIP surfaces longer.

- Extends surface lifespan and reduces liability risk.

- Offers better long-term maintenance of playground surfacing and total cost of ownership.

Low-quality EPDM:

- Saves initial cost but increases lifecycle costs due to premature failures.

- Higher safety risks and earlier need for re-surfacing.

CPSC Guidance:

Recommends regular testing over a surface’s life to ensure compliance, acknowledging that attenuation changes with aging and wear.

Conclusion

The quality of EPDM in PIP surfacing is directly tied to fall attenuation performance. Premium EPDM ensures better UV stability, compliance with safety testing for playground flooring, and easier long-term maintenance of playground surfacing. Investing in higher quality upfront provides safer playgrounds and lower costs over the surface’s life.

Relevant Links:

– ASTM F1292 Overview: https://www.astm.org/f1292-23.html

– CPSC Playground Safety Handbook: https://www.cpsc.gov/s3fs-public/325.pdf

– Example Field Study on Playground Surfaces: https://doi.org/10.xxxx/placeholder1

– UV Aging Study on EPDM: https://doi.org/10.xxxx/placeholder2

https://www.cpsc.gov/s3fs-public/325.pdf?utm_source=chatgpt.com