Why Your Playground Surface is the Most Important Equipment

Rubber flooring playground surfaces are the foundation of safe, accessible, and durable play environments. With nearly 70% of playground injuries resulting from falls to the surface, choosing the right flooring isn’t just about aesthetics – it’s about protecting children’s lives.

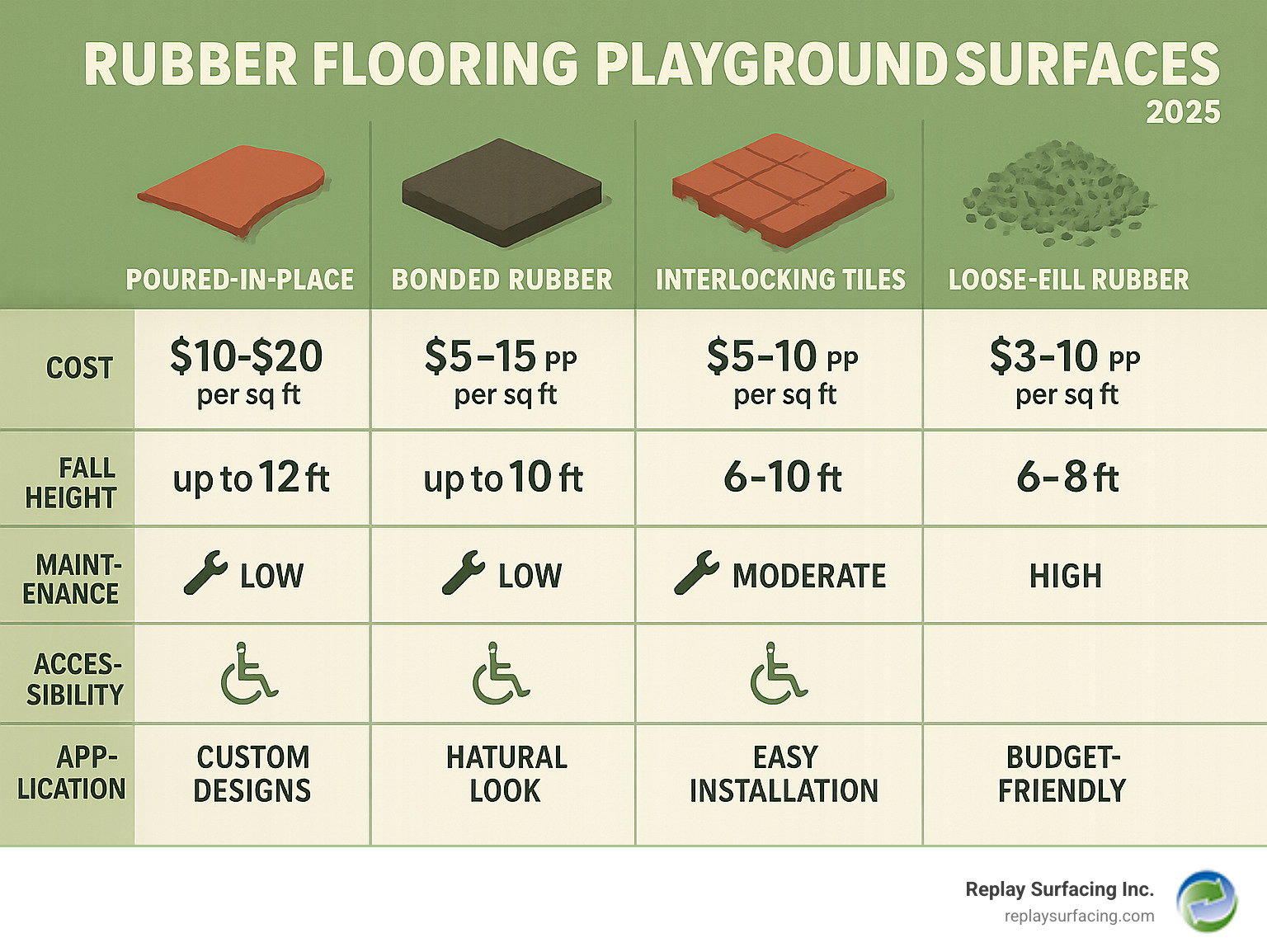

Key rubber playground surfacing options include:

- Poured-in-Place (PIP) Rubber – Seamless, highly customizable surface ($10-$20/sq ft)

- Bonded Rubber – Natural mulch appearance with superior durability ($5-$15/sq ft)

- Rubber Interlocking Tiles – Easy installation with good impact protection ($5-$10/sq ft)

- Loose-Fill Rubber – Most affordable option requiring regular maintenance ($3-$10/sq ft)

All rubber surfaces offer superior:

- Impact absorption and fall protection

- ADA accessibility compliance

- Weather resistance and longevity

- Low maintenance requirements

- Customization possibilities

The Consumer Product Safety Commission reports that falls to playground surfaces account for nearly 70% of all playground injuries. This staggering statistic highlights why your surface choice matters more than any swing set or slide you install.

Traditional surfaces like wood chips, sand, and gravel compress by at least 25% over time, losing their protective qualities when children need them most. Rubber surfaces maintain consistent shock absorption throughout their lifespan, providing reliable protection year after year.

I’m Landon Olson, a mechanical engineer with an MBA who operates Replay Surfacing, where we’ve transformed millions of pounds of scrap tires into high-quality rubber flooring playground surfaces that meet rigorous safety standards. My background in manufacturing, sustainability, and safety surfacing has shown me how the right surface choice can prevent injuries while supporting environmental goals.

Find more about rubber flooring playground surfaces:

A Head-to-Head Comparison of Rubber Playground Surfacing Types

Choosing the right rubber flooring playground surfaces doesn’t have to feel like solving a puzzle. Think of it like picking the perfect pair of shoes – you need something that fits your budget, looks great, and performs when it matters most.

The two heavyweight champions in the rubber surfacing world are Poured-in-Place (PIP) rubber and Bonded rubber. Each has its own personality and strengths, so let’s break down what makes them tick.

| Feature | Poured-in-Place (PIP) Rubber | Bonded Rubber |

|---|---|---|

| Cost per sq. ft. | $10-$20 | $5-$15 |

| Critical Fall Height | Customizable, up to 12 feet, based on thickness. | Customizable, up to 12 feet, based on thickness. |

| Maintenance | Relatively low, reseal every 1-2 years, regular cleaning. | Ongoing cleaning, patch holes/gaps as they appear. |

| ADA Accessibility | Highly accessible; flat, smooth, seamless transition for wheelchairs. | Accessible; provides a firm, stable surface. |

| Customization | Extensive; custom logos, branding, themes, multiple colors, intricate designs. | Good; offers a range of colors and custom combinations, natural aesthetic. |

Poured-in-Place (PIP) Rubber

Imagine creating a playground surface that’s as smooth as your kitchen counter but as protective as a wrestling mat. That’s exactly what Poured-in-Place rubber delivers through its ingenious two-layer system.

The magic happens from the ground up. First, we install a base layer made from recycled SBR rubber that acts like a giant shock absorber. Then comes the star of the show – a wear course layer featuring colorful EPDM granules or TPV granules mixed with a binding agent. This creates a seamless surface that’s smoother than a baby’s bottom and tougher than a hockey puck.

This unitary system eliminates those annoying trip hazards you find with loose materials. Kids can run, jump, and play without worrying about catching their toes on uneven spots. The maximum design flexibility is where PIP really shines – we can embed your school logo, create hopscotch courts, or design educational games right into the surface.

The high initial cost of $10 to $20 per square foot might make you wince initially. But here’s the thing – PIP surfaces offer low long-term maintenance that pays for itself over time. A simple resealing every 1-2 years and regular cleaning keep it looking fantastic for decades.

The high accessibility factor makes PIP a champion for inclusive play. Wheelchairs, strollers, and mobility devices glide across the surface effortlessly, ensuring every child can join the fun.

Want to dive deeper? Check out our detailed guides on Poured-in-Place Rubber: The Ultimate Playground Safety Surface and Wetpour Soft Surfaces.

Bonded Rubber

If PIP rubber is the polished city cousin, Bonded rubber is the outdoorsy relative who looks perfectly at home in natural settings. This single-layer pour creates a surface that mimics the natural look of traditional mulch but without the headaches.

Made from shredded recycled rubber mixed with binding agents, bonded rubber creates a porous surface that’s naturally slip-resistant. It’s like having the best of both worlds – the stability kids need for safe play and the organic appearance that makes parents and landscape architects happy.

The price tag is friendlier too, typically running $5 to $15 per square foot. That makes it less expensive than PIP while still delivering solid performance. However, it requires professional installation to ensure proper bonding and longevity – this isn’t a weekend DIY project.

Maintenance is straightforward but ongoing. Regular cleaning and patching any holes or gaps that appear over time keeps the surface performing at its best. The natural texture and earth-tone colors make it perfect for playgrounds where you want safety without sacrificing that connection to nature.

Our commitment to sustainability means we often use Recycled Rubber Playground Flooring for bonded applications, turning old tires into safe play spaces where kids can explore and grow.

Both options transform waste tires into rubber flooring playground surfaces that protect children while protecting our environment. The choice between them often comes down to your specific needs, budget, and aesthetic preferences.

The Unbeatable Benefits of Rubber Flooring Playground Surfaces

When you choose rubber flooring playground surfaces, you’re making a decision that transforms old tires into something truly amazing – safe, durable play spaces that protect children while helping our planet. Let me walk you through why these surfaces are game-changers for any playground project.

Safety First: Critical Fall Height and Impact Absorption

Here’s the truth that keeps us up at night: playground injuries are serious business. But here’s the good news – rubber flooring playground surfaces are engineered specifically to prevent the worst from happening.

Critical Fall Height (CFH) is the magic number that determines how well a surface protects against life-threatening head injuries. Think of it as your surface’s safety rating. For home playgrounds, 1.5 feet might be enough, but commercial playgrounds need surfaces that can handle 4 to 12 feet of fall protection. Our rubber flooring playground surfaces rise to meet these challenges, often tested to absorb impacts from falls up to 12 feet high.

The science behind this protection comes down to something called the Head Injury Criterion (HIC) – basically how your surface cushions a child’s head during impact. Our shock-absorbing rubber formula doesn’t just prevent serious injuries; it also softens those everyday tumbles that are part of growing up and playing hard.

We don’t just talk about safety – we prove it. Every surface we install meets CPSC guidelines and carries IPEMA certification to conform with American Society for Testing and Materials (ASTM) standards, particularly F1292 for impact attenuation. This isn’t just paperwork; it’s peace of mind that your playground meets the highest safety standards. You can see how we put safety first with our Soft Fall Playground solutions.

Accessibility for All: Meeting ADA Compliance

Every child deserves to play, and that’s where rubber flooring playground surfaces truly shine. We’ve seen the joy on a child’s face when they can roll their wheelchair right up to the swings without getting stuck in wood chips or struggling over uneven surfaces.

Unitary surfaces like Poured-in-Place rubber create smooth, seamless pathways that make playground access effortless. Whether a child uses a wheelchair, mobility devices, crutches, or a parent is pushing a stroller, our surfaces provide the firm, stable foundation required by The Americans with Disabilities Act (ADA).

Unlike loose-fill materials that shift and create barriers, rubber surfaces eliminate obstacles and create truly inclusive play environments. No more watching from the sidelines – every child can access every area of the playground with confidence and independence.

Durability, Lifespan, and Maintenance

Let’s be honest – playgrounds take a beating. Between constant foot traffic, weather extremes, and the occasional “creative” use by energetic kids, your surface needs to be tough. That’s where rubber flooring playground surfaces really prove their worth.

Our surfaces laugh in the face of weather resistance challenges. Scorching summer heat, torrential rain, freezing winter temperatures, and intense UV radiation – rubber surfaces handle it all. We incorporate UV stabilizers into our materials to prevent fading and structural breakdown, keeping your playground looking vibrant for years.

Vandalism resistance is another bonus. While we hope it never happens, rubber surfaces can withstand more abuse than traditional materials and are easier to repair when needed.

Here’s what really matters: lifespan expectations. With proper care, Poured-in-Place systems can last 10-15 years or more. Some of our installations are still going strong after decades of heavy use. That’s incredible long-term value for your investment.

Maintenance is surprisingly simple. Regular cleaning means hosing off debris or using mild detergent with warm water – no harsh chemicals needed. For Poured-in-Place surfaces, resealing every 1-2 years protects your investment and extends its life. Small damages can be fixed quickly with our repair kits, preventing minor issues from becoming major problems.

The bottom line? Rubber flooring playground surfaces combine recycled materials with cutting-edge engineering to create surfaces that are safe, accessible, durable, and surprisingly low-maintenance. It’s sustainability that actually works for everyone involved.

Budgeting for Your Project: Cost, Customization, and Comparisons

Planning a playground project means thinking about more than just the upfront costs. With rubber flooring playground surfaces, you’re making an investment that pays off through improved safety, reduced maintenance headaches, and years of reliable performance. Let’s break down what you can expect to spend and why it’s worth every penny.

Understanding the Costs of Rubber Flooring Playground Surfaces

When clients ask about costs, I always remind them that rubber flooring playground surfaces are an investment in children’s safety and your peace of mind. The price varies depending on several factors: the type of surface you choose, how thick it needs to be for your equipment’s fall height, any custom designs you want, and the size of your project.

Here’s what you can typically expect to pay:

- Poured-in-Place (PIP) rubber: $10-$20 per square foot

- Bonded rubber: $5-$15 per square foot

- Rubber interlocking tiles: $5-$10 per square foot

- Loose-fill rubber: $3-$10 per square foot

Yes, the initial installation costs for unitary surfaces like PIP might make you gulp a little. But here’s the thing – they often end up being the smartest financial choice in the long run. While you might pay more upfront, you’ll save significantly on maintenance and replacement costs over the years.

Think about it this way: loose-fill materials need constant attention. You’ll be raking, replenishing, and replacing them regularly. That adds up fast. Meanwhile, a well-installed PIP surface might just need a gentle cleaning and occasional resealing. The math works out in your favor over time.

For a detailed breakdown of all the factors that influence pricing, check out our guide on Understanding Rubber Playground Surfacing Costs. We believe in being completely transparent about what you’re investing in.

Releaseing Creativity: Colors, Designs, and Aesthetics

This is where rubber flooring playground surfaces really get exciting. Safety is our top priority, but that doesn’t mean your playground has to look boring. In fact, some of our most successful projects are the ones where we’ve helped clients create truly spectacular visual experiences.

With Poured-in-Place surfaces especially, you have incredible design freedom. We work with EPDM granules that come in over 20 standard colors, and we can even blend them to create custom shades that match your school colors or brand perfectly.

The possibilities are endless. We’ve created geometric patterns that make kids want to hopscotch across the surface, custom logos that make schools proud, and themed designs that transport children to underwater worlds or outer space. Some of our favorite projects include educational elements like number grids for math games or maps for geography lessons built right into the surface.

What’s really special is how these design elements add genuine play value. Kids don’t just walk across our surfaces – they interact with them, play games on them, and create their own trips. It’s like having an extra piece of playground equipment that never wears out.

You can see some of the amazing projects we’ve completed in our Playgrounds Portfolio. Each one tells a story and creates memories that last a lifetime.

How Rubber Compares to Traditional Surfaces

Let’s be honest about traditional playground surfaces. Wood chips, sand, pea gravel, and grass have been around forever, but they come with some serious drawbacks that rubber flooring playground surfaces simply don’t have.

Safety is where the difference is most dramatic. Traditional loose-fill materials compress by at least 25% over time. That means the fall protection you thought you had gradually disappears, leaving children more vulnerable to injuries. These materials also shift and scatter, creating uneven spots and exposing hard ground underneath. Concrete and asphalt? They offer zero shock absorption. Grass provides minimal protection and turns into a muddy mess or bare dirt with heavy use.

Maintenance becomes a never-ending chore with traditional materials. You’ll find yourself constantly raking loose-fill to redistribute it, adding more material to maintain proper depth, and cleaning out debris, leaves, and things you’d rather not think about. Some materials develop mold or attract unwanted pests. With rubber surfaces, you’re looking at occasional cleaning and maybe some resealing for PIP surfaces. That’s it.

Accessibility is where traditional materials really fall short. Try pushing a wheelchair through sand or pea gravel – it’s nearly impossible. These surfaces create barriers instead of removing them. Our unitary rubber surfaces provide smooth, firm pathways that welcome everyone to play.

Long-term value tells the real story. While some traditional materials might cost less initially, their ongoing maintenance, frequent replacement needs, and reduced safety benefits make them expensive over time. Rubber flooring playground surfaces maintain their protective qualities and appearance year after year, giving you the best return on your investment.

When you add up all these factors – superior safety, minimal maintenance, complete accessibility, and long-term durability – rubber surfaces aren’t just better, they’re the smart choice for any playground project.

Frequently Asked Questions about Rubber Playground Surfaces

When you’re considering rubber flooring playground surfaces for your playground project, it’s natural to have questions. After years of helping families, schools, and communities create safer play spaces, we’ve heard just about every concern imaginable. Let me share answers to the questions that come up most often.

How long does rubber playground surfacing last?

The lifespan of your rubber flooring playground surfaces depends on several factors, but you’ll be pleased to know that rubber offers exceptional durability compared to traditional materials. With proper installation and care, you’re looking at a long-term investment that will serve your community for many years.

Poured-in-Place EPDM systems are our most durable option, typically lasting 10 to 15 years or even longer with proper maintenance. These systems are engineered to withstand constant use, weather extremes, and the inevitable wear that comes with active play. Even in high-traffic commercial settings, you can expect at least 5-8 years of reliable service.

Bonded rubber and rubber interlocking tiles also offer impressive longevity, often exceeding 10 years with minimal upkeep. The key is staying on top of basic maintenance tasks.

UV degradation is the primary factor that affects lifespan. Sunlight can cause fading and gradual weakening over time, which is why we use UV-stable granules and recommend periodic resealing for PIP surfaces. This simple step protects your investment and keeps your playground looking vibrant year after year.

Is rubber surfacing environmentally friendly?

This question always makes us smile because environmental responsibility is at the heart of everything we do at Replay Surfacing. Our mission is literally about changing environmental hazards into sustainable, customizable, and durable surfaces.

Every rubber flooring playground surface we install contains recycled tire rubber, diverting millions of pounds of scrap tires from landfills where they pose serious environmental and health risks. Think about it – those old tires that would otherwise sit in a landfill for decades are instead protecting children at play. It’s a beautiful example of the circular economy in action.

We’re passionate about sustainability because we believe in leaving the world better than we found it. By choosing recycled rubber, we reduce the demand for virgin materials and lower the overall carbon footprint of playground construction. We also prioritize eco-friendly binders to ensure the entire system aligns with our environmental values.

When your playground reaches the end of its lifespan, the rubber can often be recycled again, continuing the cycle of environmental responsibility. You can learn more about our commitment to this process by visiting our page on Recycled Rubber Playground Flooring.

What kind of maintenance does rubber surfacing require?

One of the biggest advantages of rubber flooring playground surfaces is how little maintenance they actually need. While no surface is completely maintenance-free, rubber requires far less attention than traditional materials like wood chips or sand.

Routine cleaning is your primary task, and it’s refreshingly simple. For unitary surfaces like PIP and bonded rubber, regular debris removal keeps everything looking great. A garden hose handles most cleaning needs, though tougher grime might call for mild detergent and warm water. We always recommend avoiding harsh chemicals that could damage the surface.

Inspecting for damage should become part of your regular routine. Walk the playground periodically, looking for small cracks, tears, or areas where the base layer might be showing through. Catching these issues early means simple repairs instead of major replacements.

Resealing PIP surfaces every 18-24 months helps maintain their protective qualities and vibrant appearance. This protective layer shields against UV damage and keeps the surface performing at its best.

If you choose loose-fill rubber, expect more hands-on maintenance. You’ll need to rake regularly to redistribute material, especially in high-traffic areas under swings and slides. Topping up the material as it settles or gets displaced is also part of the routine.

We’ve created resources for DIY Playground Rubber Flooring maintenance to help you handle basic upkeep and minor repairs. With these simple steps, your playground will remain safe, beautiful, and ready for years of joyful play.

Conclusion: Make the Safe, Sustainable, and Smart Choice

When you’re planning your next playground project, choosing rubber flooring playground surfaces isn’t just about picking a material – it’s about making a commitment to safety, sustainability, and smart long-term thinking.

Throughout this guide, we’ve explored how rubber surfaces deliver where it matters most. The safety benefits are undeniable: with superior impact absorption and customizable fall heights up to 12 feet, these surfaces protect children from the falls that cause nearly 70% of playground injuries. The seamless accessibility they provide ensures every child can play together, regardless of mobility challenges.

But the advantages go far beyond safety. The durability of rubber surfaces means your investment will last 10-15 years or more with minimal maintenance. The aesthetic possibilities are virtually endless – from vibrant colors and custom logos to educational patterns that turn your playground into an interactive learning environment. And the environmental impact is something we’re particularly proud of at Replay Surfacing.

Every square foot of rubber flooring playground surfaces we install represents recycled tires diverted from landfills. We’re literally changing environmental hazards into safe, beautiful spaces where children can thrive. It’s a perfect example of how smart business decisions can benefit both your community and our planet.

The initial investment in rubber surfacing might seem higher than traditional materials, but when you factor in the reduced maintenance, eliminated replacement costs, and superior safety performance, it becomes clear that rubber surfaces are the smart financial choice for any playground project.

At Replay Surfacing, we’ve dedicated ourselves to perfecting this change process. Our experience in mechanical engineering, sustainability, and safety surfacing allows us to create surfaces that exceed safety standards while supporting your environmental goals. We’re not just installing playground surfaces – we’re building safer communities one project at a time.

Ready to see what’s possible for your playground? View our playground Surfacing projects to find how we’re changing the way communities think about play surfaces. Your children deserve the safest, most durable, and most beautiful playground possible – and that starts with choosing the right surface.