Why Rubber Resin Playground Surfaces Are Changing Child Safety

Rubber resin playground surfaces combine recycled tire rubber with polyurethane binders to create seamless, impact-absorbing safety surfaces. Here’s what you need to know:

Key Benefits:

– Safety: Protects from falls up to 11.5 feet (3.5 meters) when properly installed

– Durability: Lasts 8-12 years with minimal maintenance

– Cost: $8-18 per square foot for areas over 1,000 sq ft

– Sustainability: Made from 100% recycled vehicle tires

– Accessibility: ADA-compliant smooth surface for wheelchair access

Main Types:

– Resin bound rubber mulch: Granules mixed with clear resin

– Wet pour (poured-in-place): Two-layer system with SBR base and EPDM top coat

– Hybrid systems: Combines both methods for 20% cost savings

As one facility manager shared: “We used to rake and redistribute our loose mulch daily—now our maintenance team can focus on other priorities.”

Every playground deserves a surface that keeps kids safe while supporting your environmental goals. Traditional wood chips and sand create ongoing maintenance headaches, harbor pests, and offer limited fall protection. Rubber resin playground surfaces solve these problems by changing waste tires into durable, colorful safety zones that meet strict ASTM F1292 and BS EN 1177 standards.

I’m Landon Olson, and through my work at Replay Surfacing, I’ve helped transform millions of pounds of scrap tires into high-quality rubber resin playground surfaces across North America. My mechanical engineering background and MBA help me apply both technical expertise and business insight to create sustainable surfacing solutions that exceed safety standards while supporting your budget and environmental goals.

Rubber resin playground vocab to learn:

– epdm rubber playground

– wetpour rubber surfacing

– resin bound rubber crumb

What Is Rubber Resin Playground Surfacing?

Rubber resin playground surfacing transforms discarded vehicle tires into high-performance safety flooring that protects children when they fall.

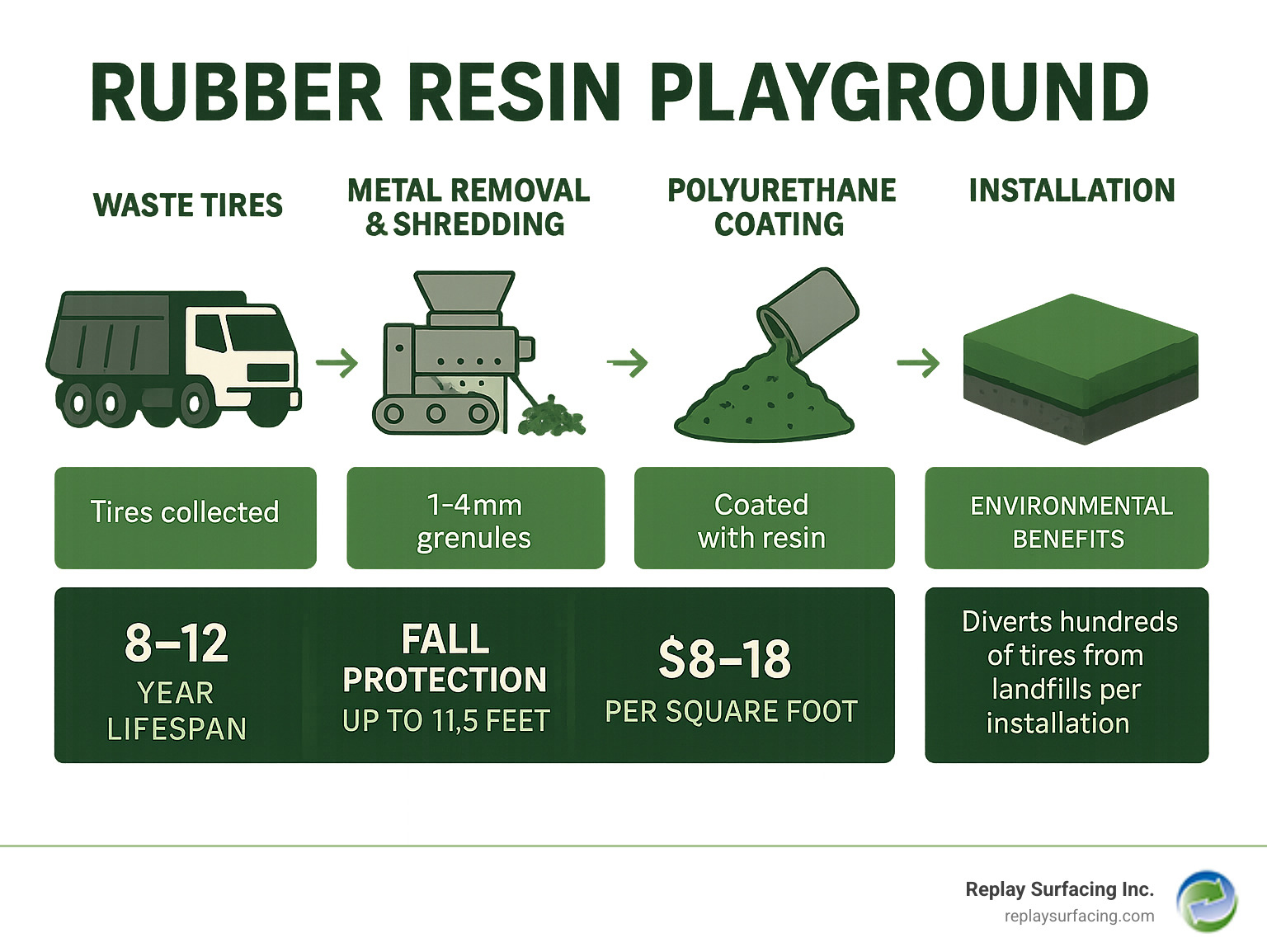

The process starts with collecting end-of-life tires from recycling programs. After removing all metal components, tires are shredded into precise 1-4mm rubber granules. These particles get cleaned, sorted by size, and coated with UV-stable pigments and low-VOC polyurethane binders.

The polyurethane binder acts like flexible glue that holds crumb rubber particles in place while allowing the surface to compress and rebound when kids land on it. This creates resin bound mulch—a surface that’s both durable and forgiving.

Two main installation methods exist: Wet pour systems involve mixing materials on-site and applying them while liquid, creating seamless surfaces with unlimited design possibilities. Pre-mixed alternatives get troweled into place for simpler installations.

EPDM (Ethylene Propylene Diene Monomer) granules create vibrant colored surfaces, while SBR (Styrene-Butadiene Rubber) provides shock-absorbing foundation for impact protection.

Properly installed surfaces feature porosity—water drains naturally through tiny spaces between bound particles, preventing slip hazards while supporting sustainable drainage.

The critical test is critical fall height—the maximum height from which a child can fall without risk of life-threatening head injury. A 50mm thick surface protects children from falls up to 2.4 meters (nearly 8 feet).

Scientific research on recycled tire rubber safety confirms that properly processed tire rubber poses no health risks while providing superior safety performance.

The Science Behind Safety in a Rubber Resin Playground

Every rubber resin playground surface must pass rigorous ASTM F1292 testing, involving dropping a specialized headform from various heights and measuring transmitted g-force.

The critical threshold is 200 g’s with Head Injury Criteria (HIC) values under 1000. When impact occurs, the surface compresses to absorb energy, then rebounds to original thickness. This shock attenuation dramatically reduces force transmitted to a child’s body.

European BS EN 1177 standards use similar methods, ensuring consistent global performance. Quality surfaces maintain performance across typical climate temperature ranges.

Main Material Types in a Rubber Resin Playground

Resin bound rubber mulch offers cost-effective solutions for larger areas. We mix 100% recycled tire rubber granules with polyurethane resin and hand-trowel for seamless surfaces with excellent drainage.

Poured-in-place systems provide maximum customization with two distinct layers: SBR shock pad base (20-40mm thick) handles impact absorption, while EPDM wear layer (10-15mm thick) provides color and durability.

Hybrid cushion systems combine both approaches—20mm base layer plus 20mm resin bound top—reducing costs by 20% while maintaining safety performance.

More info about EPDM systems explains customization options for specific applications.

Planning & Installing a Rubber Resin Playground Surface

Successful rubber resin playground installation starts with thorough planning. We survey drainage patterns, check soil conditions, and map utilities to prevent problems.

Foundation work uses MOT Type 1 sub-base—engineered aggregate from 40mm stones to fine particles creating perfect stability and drainage balance. Geotextile membrane prevents weeds while allowing drainage.

Weather timing is critical. We won’t start when temperatures drop below 5°C or rain threatens within 24-48 hours. Polyurethane binder needs consistent dry conditions for proper curing.

Mixing requires precision—maintaining 5:1 weight ratio of rubber granules to resin. Once mixed, we have 60 minutes before resin sets.

ADA compliance means controlling slopes below 1:20 (5%) maximum and creating smooth transitions. Surfaces must be firm enough for wheelchair navigation while providing impact protection.

Quality control happens continuously—checking mixing ratios, measuring thickness, monitoring surface smoothness and temperature.

Sub-base & Drainage Requirements for Rubber Resin Playground Success

MOT Type 1 sub-base creates stable foundation through carefully graded granite, limestone, or crushed concrete mixture. Larger stones provide strength while smaller particles prevent settling. Proper compaction achieves 95% standard Proctor density.

Existing concrete or asphalt surfaces work excellently after cleaning, crack repair, and primer application—saving demolition costs while providing superior foundation.

SUDS compliance supports stormwater management as surfaces allow rainwater infiltration rather than runoff. Permeability testing shows 200-400mm per hour infiltration rates.

Edge restraint using treated lumber, recycled plastic, or concrete prevents maintenance issues and keeps surfaces performing throughout their lifespan.

Step-by-Step Wet Pour & Mulch Installation Guide

Site preparation starts with utility marking and safety zones. Excavation goes 100-150mm deep depending on design requirements.

MOT Type 1 sub-base installation requires patience. Geotextile membrane gets 150mm overlaps, edge restraints follow, then level checking before proceeding.

Shock pad installation mixes SBR rubber crumb with polyurethane binder, applied to specified thickness (20-40mm). Hand tamping ensures consistency, followed by 4-6 hour cure period.

Wear layer application brings color through EPDM granules mixed with color-matched binder. Hand-trowel technique uses soapy water lubrication for smooth finishing.

Quality control includes critical fall height testing using ASTM F1292 protocols, drainage verification, and specification compliance before completion.

More info about poured in place rubber provides detailed technical specifications.

Cost, Lifespan & Maintenance: Getting the Most from a Rubber Resin Playground

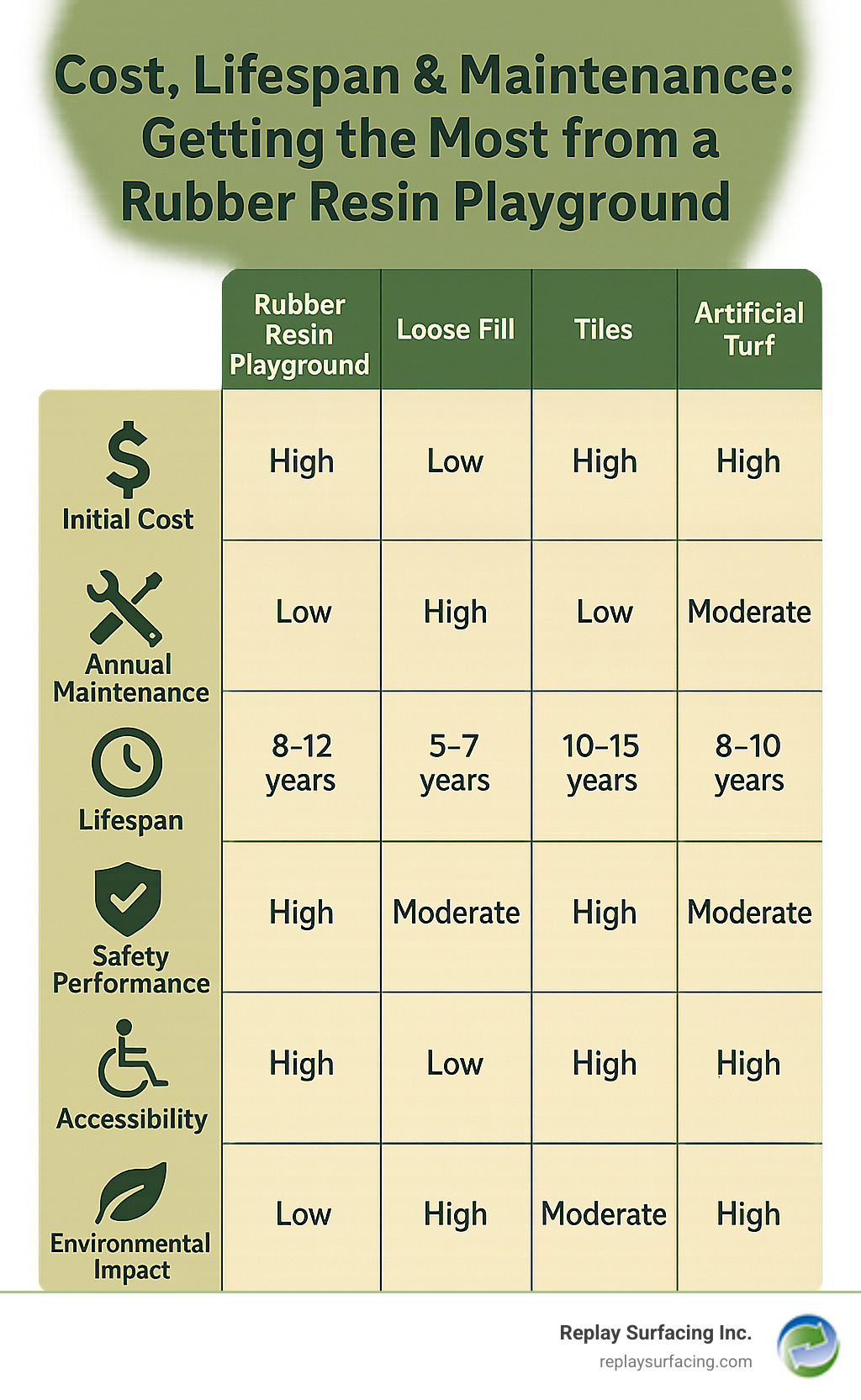

Resin bound rubber mulch costs $8-16 per square foot for areas over 1,000 square feet. Wet pour systems range $9-18 per square foot. Hybrid systems save 20% compared to full wet pour while delivering identical safety performance.

A properly installed rubber resin playground surface serves communities for 8-12 years—proven across different climates and usage levels. UV-stable pigments resist fading while flexible resin formulations handle freeze-thaw cycles.

Maintenance becomes simple: sweep weekly, power-wash quarterly, test critical fall height annually, plus bi-annual sealant application when specified. Annual maintenance costs just $0.50-1.00 per square foot—a fraction of loose-fill system demands.

While rubber resin playground surfaces require higher initial investment, total ownership costs often favor resin-bound systems within 3-5 years when factoring reduced maintenance, improved safety, and environmental benefits.

Repairing & Extending the Life of Your Rubber Resin Playground Surface

DIY patch kits handle small repairs under one square foot. Each contains pre-measured rubber granules, colored EPDM, and polyurethane binder. Process involves cutting damaged sections, preparing clean edges, mixing repair material, and hand-troweling to match surrounding texture.

Color matching requires finesse since outdoor surfaces fade gradually. Order repair materials during original installation and let them age naturally in storage for better color matches.

Sealant cycles every 2-3 years add surface life by refreshing polyurethane binder and restoring flexibility—preventive maintenance costing a fraction of replacement.

Choose between micro-repairs versus re-topping based on damage extent. Isolated damage responds to patches, but widespread wear might justify fresh wear layer installation over existing shock pad at 60% of replacement cost.

More info about surfacing costs helps with repair versus replacement decisions.

Design, Accessibility & Environmental Benefits

Rubber resin playground surfaces offer incredible design flexibility while solving accessibility challenges and environmental problems.

Design possibilities include color blends that gradually shift between hues, school colors creating pride underfoot, and logos and educational games changing safety surfacing into interactive learning zones. We’ve created alphabet grids, hopscotch courts, number games, and even periodic tables for outdoor chemistry lessons.

These surfaces support seamless wheelchair routes throughout play areas. Unlike loose mulch creating barriers, rubber resin playground surfaces provide firm, stable pathways meeting ADA requirements without compromise.

Sensory zones benefit every child through varied textures using different EPDM granule sizes, high-contrast color combinations, and tactile patterns providing rich sensory feedback.

Environmentally, each installation diverts 600-800 passenger tires from landfills. The carbon footprint benefits from requiring less energy than virgin materials, maximized through 8-12 year lifespans.

Why a Rubber Resin Playground Supports Universal Play

ADA slope requirements limit accessible routes to 5% maximum grade. Poured-in-place installation allows precise grade control creating smooth transitions meeting accessibility standards.

Firm-stable surface requirements ensure mobility devices steer safely without getting stuck. The bound structure provides consistent support throughout surface life, with adjustable firmness balancing accessibility and impact absorption.

Inclusive markings help visually impaired children steer independently. High-contrast color combinations, tactile strips signaling transitions, and raised elements providing wayfinding integrate into attractive designs.

Turning Waste Tires into Play Spaces Kids Love

Tire stockpiles pose serious environmental risks—mosquito breeding grounds, fire hazards, and chemical leaching. Processing these into playground surfaces eliminates risks while creating decade-long community assets.

VOC-safe binders use water-based polyurethane systems meeting strictest indoor air quality standards. Third-party testing confirms properly cured surfaces pose no health risks.

Drainage performance improves environmental outcomes through porous structure preventing puddles while filtering rainwater naturally, reducing storm sewer burden and preventing erosion.

Heat concerns show properly formulated surfaces run only slightly warmer than asphalt, significantly cooler than metal equipment. Light colors minimize heat buildup.

More info about recycled rubber benefits explains continuous environmental improvements.

Frequently Asked Questions about Rubber Resin Playground Surfaces

Parents, facility managers, and school administrators ask us the same questions over and over. After installing thousands of rubber resin playground surfaces across North America, we’ve learned exactly what matters most to the people who use and maintain these spaces.

Let me share the answers to the three questions that come up in nearly every conversation.

What critical fall height can a rubber resin playground achieve?

The magic number everyone wants to know: how high can a child fall and still be protected? With a standard 50mm (2-inch) thick rubber resin playground surface, we protect children from falls up to 2.4 meters—that’s nearly 8 feet high.

Need protection from even higher play structures? We can build thicker systems that protect from falls up to 3.5 meters (11.5 feet) or more. The key is matching the surface thickness to your specific playground equipment heights.

For wet pour systems, we calculate protection by combining both layers. A typical 30mm SBR shock pad with a 20mm EPDM wear layer provides the same fall protection as a 50mm resin bound system. It’s like having a custom-engineered safety net under every piece of equipment.

The testing process is surprisingly precise. We drop a specialized headform (think crash test dummy head) from various heights and measure exactly how much force travels through the surface. To pass ASTM F1292 standards, surfaces must keep peak forces below 200 g’s and Head Injury Criteria values under 1000.

One playground director told us: “Knowing our surface protects from 8-foot falls gives me peace of mind every time I watch kids climb our tallest structures.”

Can it be installed over existing asphalt or concrete?

Absolutely! This is one of our favorite installation scenarios because it saves you money while creating an even better foundation than starting from scratch.

Your existing asphalt or concrete surface makes an excellent base—provided it’s structurally sound. We clean it thoroughly, repair any cracks or damage, then apply a primer coat to ensure the new rubber bonds perfectly to the old surface.

The overlay approach eliminates demolition and disposal costs entirely. No jackhammers, no dumpsters, no disruption to surrounding landscaping. We simply build the new safety surface right over what’s already there.

Drainage does require some planning when we overlay existing surfaces. The porous rubber resin playground surface allows water to filter through naturally, but that water needs somewhere to go once it reaches the base level. We might install edge drains or adjust the surface profile slightly to prevent any pooling.

Schools especially love this approach because it minimizes disruption during the installation process. Kids can often continue using other areas of the playground while we work, and the project timeline stays predictable.

Can rubber resin surfacing be installed over existing concrete or asphalt?

Yes. In many cases, existing hard surfaces can serve as a stable foundation for rubber resin systems, as long as they are structurally sound and properly prepared. This approach often saves on demolition costs and shortens installation timelines.

How hot does a rubber resin playground get in summer?

Here’s the honest answer: rubber resin playground surfaces do get warm in direct sunlight, typically running 5-15°F warmer than surrounding grass areas. That’s about the same as asphalt, but significantly cooler than metal playground equipment that can become dangerously hot.

Color selection makes a huge difference. Light colors like beige, tan, and light gray stay much cooler than dark colors like black or navy blue. We often recommend earth-tone blends that look great while keeping temperatures comfortable for bare feet.

Smart installation techniques help too. Proper drainage prevents water from pooling and creating hot spots, while adequate surface thickness prevents heat from conducting up from the sub-base below.

In extremely hot climates like Arizona or Texas, we work with clients to plan additional cooling strategies. Shade structures, misting systems, or specialized heat-reflective additives can keep surface temperatures in the comfort zone even during peak summer heat.

One facility manager in Phoenix shared: “We installed a light tan surface with partial shade coverage, and even in July, kids can play comfortably during our morning camp hours.”

The bottom line? With thoughtful color selection and proper planning, heat doesn’t have to limit your rubber resin playground enjoyment.

Conclusion

Every child deserves a safe place to play. That’s the simple truth driving everything we do at Replay Surfacing Inc.

We saw two problems needing solutions: playgrounds that weren’t safe enough, and millions of waste tires in landfills. The answer was beautifully simple—turn discarded tires into rubber resin playground surfaces that protect children while protecting our planet.

We’ve installed millions of square feet across Charlotte NC, Columbia SC, Raleigh NC, Sanford NC, Tucson AZ, Connecticut, Indiana, Nashville TN, Beaverton OR, and Lake Charles Louisiana. Each project teaches us about creating spaces where all children play together safely.

The numbers tell part of the story: fall protection up to 11.5 feet, 8-12 year lifespans, 20% cost savings with hybrid systems. But the real story happens watching kids play—children in wheelchairs accessing equipment for the first time, facility managers relieved from raking scattered mulch, communities proud of colorful playgrounds built from recycled materials.

Rubber resin playground surfaces work through smart engineering solving real problems. Impact absorption science keeps kids safer. Durability means lasting investment. Sustainability means environmental responsibility. Accessibility means every child gets to play.

The best playgrounds aren’t just safe—they’re inspiring. We offer unlimited colors, custom graphics, and educational markings making your playground as unique as your community while meeting strictest safety standards.

Maintenance becomes manageable: basic sweeping and occasional washing replace constant raking, organic buildup removal, and pest control. Your team focuses on creating great experiences for kids.

After thousands of installations, rubber resin playground surfaces represent safe play’s future. They turn environmental waste into community assets, make playgrounds accessible to previously excluded children, and last longer while costing less over time.

Ready to see what’s possible? Our team loves helping communities design surfaces meeting specific needs—maximum fall protection, custom school colors and logos, or budget-friendly solutions maintaining safety standards.

More info about our playground safety surfacing company shows our commitment to quality, safety, and environmental responsibility.

Contact us today to start your playground change conversation. We’ll help you understand options, plan budgets, and create rubber resin playground surfaces serving your community for years. Every child deserves safe play spaces—every community deserves playgrounds they can be proud of.